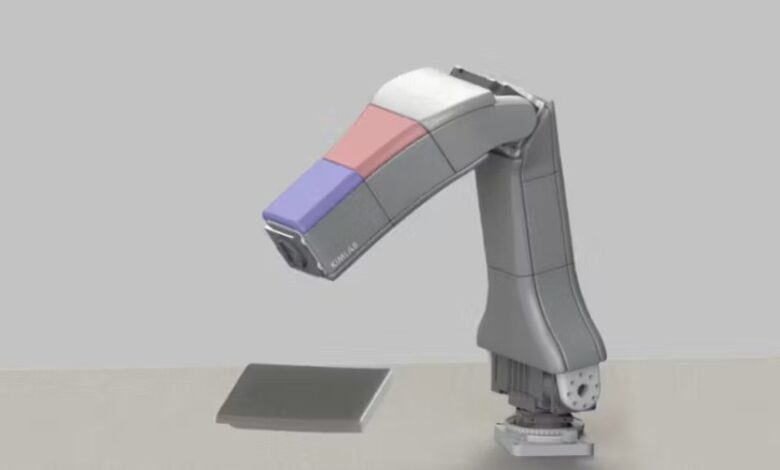

3D Printed Soft Skin Pads Offer Enhanced Safety and Usability in Robotics

Researchers at the University of Illinois Urbana-Champaign have unveiled a cost-effective solution to equip robots with a human-like sense of touch. Leveraging the power of 3D printing technology, these innovative soft skin pads not only provide a gentle touch but also serve as mechanical pressure sensors, heralding an extensive range of new possibilities in the field of robotics.

Traditionally, tactile sensors for robots have been complex and expensive, limiting their widespread adoption. However, the team led by Professor Joohyung Kim has shattered these barriers by demonstrating that functional and durable alternatives can be produced inexpensively using off-the-shelf 3D printers.

“Since it’s just a question of reprogramming a 3D printer, the same technique [of applying 3D printed soft skin pads] can be easily customized to different robotic systems,” Professor Kim stated when discussing the process of incorporating 3D printing. “Robotic hardware can involve large forces and torques, so it needs to be made quite safe if it’s going to either directly interact with humans or be used in human environments. It’s expected that soft skin will play an important role in this regard since it can be used for both mechanical safety compliance and tactile sensing.”

These soft skin pads achieve their remarkable capabilities through a combination of advanced materials and cutting-edge design. Developed from thermoplastic urethane using readily available Raise3D E2 3D printers, the pads feature a soft outer layer enveloping a hollow infill section. When compressed, the air pressure within the pads changes, enabling the detection of vibration, touch, and pressure by connected pressure sensors.

Given their straightforward manufacturing process and affordability, 3D printed parts offer an attractive option for integration into emerging robotic systems. The use of 3D printing can be particularly beneficial in scenarios where the maintenance and cleaning of components pose significant financial or logistical challenges. Kim outlined how 3D printing can navigate these hurdles, stating, “Imagine you want to use soft-skinned robots to assist in a hospital setting,” he said. “They would need to be regularly sanitized, or the skin would need to be regularly replaced. Either way, there’s a huge cost. However, 3D printing is a very scalable process, so interchangeable parts can be inexpensively made and easily snapped on and off the robot body.”

The soft touch pad design incorporates air which pressurized areas of the pad on touch.

As the demand for safer, more intuitive robots grows, 3D printed soft skin pads offer a compelling solution for a more comfortable, sensitive interaction between human patients and machines. Moreover, their affordability and versatility make them accessible to many users, paving the way for widespread adoption in various fields.

What do you think of the benefits and applications of these 3D printed soft skin pads? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: University of Illinois Urbana Champaign