Pudu Robotics rolls out robots for navigating industrial environments

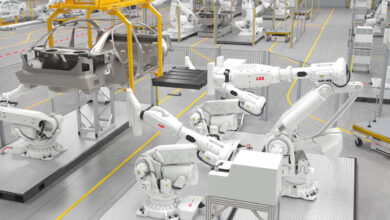

Pudu Technology Inc., a developer of service robotics, today announced the launch of its first line of robots designed expressly for industrial applications.

Pudu makes commercial robotics solutions, such as delivery robots, particularly for the hospitality and restaurant sector. The company has shipped more than 70,000 units globally and is a supplier for Walmart Inc., Pizza Hut LLC and KFC Corp.

The new PUDU T300 represents the company’s first foray into building a robot for industrial work. It can navigate through narrow passageways and transferring heavy or hazardous materials.

Today’s manufacturing environments have struggled to keep up with increasing demands for workers to keep up with advanced tasks such as maintaining supply lines, moving items between different locations and handling dangerous or arduous tasks. Lifting and moving heavy objects among them, robots have become commonplace in assisting workers get their jobs done faster.

An April 2024 joint study from the Manufacturing Institute and Deloitte noted the United States manufacturing industry will need up to 3.8 million jobs to be filled within the next decade. And, around half of those jobs remain unfilled because of current applicant gaps. Robots that can address easy labor needs, such as moving objects from place to place, mean that people need not be hired for roles of simply moving materials around the warehouse.

“There is a huge demand from industrial clients for automated, flexible robotics solutions that can operate continuously to meet high production rates and improve operational efficiency,” said Felix Zhang, founder and chief executive of Pudu Robotics. “As manufacturers struggle to attract and retain talent, the T300 fills the immediate gap by seamlessly integrating with facilities’ current processes as well as optimizing operations to spur sector-wide innovation.”

The T300 is designed to operate around people, so it has a “cute” form factor, with a display “face” that displays its intentions and includes high-brightness indicator lights that give those around an idea of where it’s going. The platform is also slim so it can navigate narrow passageways as small as 23.6 inches and cross 0.7-inch thresholds. It can carry objects up to 661 pounds.

For moving around factory and warehouse floors, the robot combines a fusion of laser and visual tracking for positioning that allows it very precise navigation capabilities. The company said this makes it highly adaptable in high-ceiling factories, allowing it to update its internal map in real time based on actual site changes. It’s built on the company’s proprietary VSLAM+ technology, which allows for marker-free navigation.

The robot can also interact with doors, elevators and the internal network of warehouses and factories through internet of things capabilities giving it secure access to production processes. This means that it can automate navigation through areas similar to human workers without the need for its movements to be overseen. The robot also recharges automatically and its battery can be quickly swapped, which means it can remain in continuous operation.

Pudu said that it expects the T300 could be deployed in production lines throughout the entire manufacturing sector, including electronics casting, automotive parts processing, metalworking and semiconductor fabrication.

Image: Pudu Robotics

Your vote of support is important to us and it helps us keep the content FREE.

One click below supports our mission to provide free, deep, and relevant content.

Join our community on YouTube

Join the community that includes more than 15,000 #CubeAlumni experts, including Amazon.com CEO Andy Jassy, Dell Technologies founder and CEO Michael Dell, Intel CEO Pat Gelsinger, and many more luminaries and experts.

THANK YOU