Smart Lab Revolutionizes Nanomaterial Development

In a recent study published in Advanced Functional Materials, scientists from the Korea Institute of Science and Technology created an AI-powered robotic platform that can synthesize nanomaterials much faster and with consistent quality. This “Smart Lab” could revolutionize material development.

Before its effective development in the early 1900s, the Haber-Bosch technique required over 10,000 trials to find a catalyst for ammonia synthesis. The entire process of creating new materials, from design to commercialization, is expensive and time-consuming.

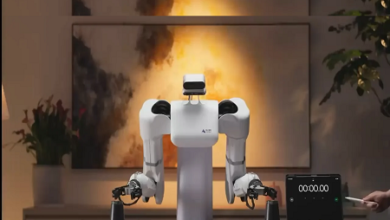

Lately, scientists have been attempting to use artificial intelligence (AI) to reduce development time. Without human intervention, material development research can be carried out 365 days a year, 24 hours a day, with the help of robots.

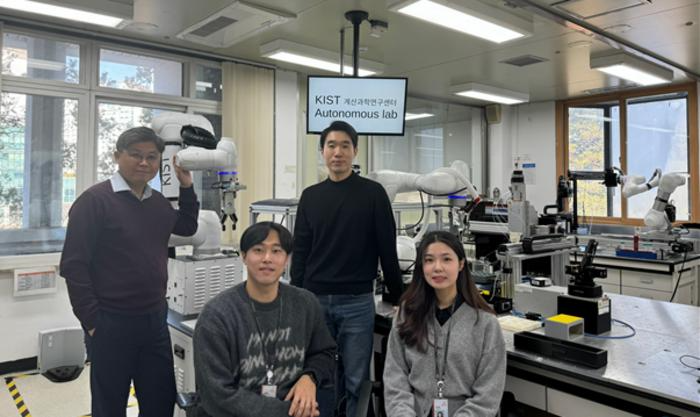

Dr. Sang Soo Han and Dr. Donghun Kim from the Computational Science Research Center, along with Professor Kwan-Young Lee from the Department of Chemical Engineering and Biotechnology at Korea University (under President Kim Dong-won), have pioneered a tailored synthesis platform for nanomaterials named Smart Lab, integrating AI and robotics.

The KIST-Korea University collaborative research team first created an automated apparatus that uses a robotic arm to produce nanoparticles and evaluate their optical characteristics. This was combined with AI technology to create a smart laboratory for the tailored synthesis of nanomaterials. With this, researchers can easily synthesize nanomaterials that satisfy their needs by entering the desired material qualities.

Compared to basic automated devices, the AI technology integrated into the Smart Lab platform increases the efficiency of material discovery by more than 500 times by combining a Bayesian optimization method with early stopping technology.

The outcomes of human studies depend so heavily on the study setting and the skill of the researchers that it is often difficult to produce repeatable findings. The established smart lab has the benefit of creating enormous numbers of reliable, high-quality data.

Additionally, the researchers created an AI system to guarantee smart lab security. Unmanned smart labs do not pose a risk of injury to researchers, yet it is challenging to prevent safety incidents, such as breakdowns caused by robot overload.

To anticipate and stop these safety mishaps, the researchers created DenseSSD, an AI vision system deployed in the smart lab. DenseSSD finds things in the lab, including materials and equipment used for research, and alerts users to any anomalies so they can take the necessary action.

The smart lab platform, which enables material development without human intervention, will be a new R&D paradigm that can solve the problem of declining research manpower due to aging.

Dr. Sang Soo, Computational Science Research Center, Korea Institute of Science and Technology

Dr. Donghun Kim said, “In the future, we plan to incorporate interactive language models such as ChatGPT to make it easier for non-experts to use the smart lab.”

The research team intends to expand the Smart Lab platform to include more material areas, such as catalysts, batteries, and displays.

Journal Reference:

Yoo, J. H., et al. (2024) Bespoke Metal Nanoparticle Synthesis at Room Temperature and Discovery of Chemical Knowledge on Nanoparticle Growth via Autonomous Experimentations. Advanced Functional Materials. doi.org/10.1002/adfm.202312561.