Rivelin Robotics automating metal post-processing through new Innovate UK project

UK-based 3D printing post-processing firm Rivelin Robotics is leading a UK government-funded project to deliver a digital process for the automated finishing of metal 3D printed parts. In particular, the project targets the post-processing of aerospace parts, orthopaedic implants and gas turbine components.

Called Project CAMPFIRE (Certified Additive Manufactured Parts Finished with Intelligent Robotics Engine), the 15-month venture sees Rivelin collaborate with Attenborough Medical, GKN Aerospace and Materials Solutions, a Siemens Energy business.

All three companies have adopted Rivelin’s Netshape Robots, which leverage 3D vision and force control algorithms to finish metal 3D printed parts with minimal human input. Robotics firm YASKAWA EU and grinding technology specialist Saint-Gobain Abrasives are also contributing to the project by delivering key hardware.

It is hoped that the project, which is part of UK Research and Innovation’s MSI Challenge, will demonstrate the value of Netshape Robots in highly regulated industries. These include the aerospace, medical, energy, defense and automotive sectors.

CAMPFIRE is being delivered by Innovate UK, the Engineering and Physical Sciences Research Council, and the Economic and Social Research Council. The project is one of 11 grants, worth £3.7 million, awarded to late-stage robotics and automation initiatives seeking to improve productivity, sustainability and resilience in manufacturing.

“Leading Project CAMPFIRE is a significant milestone for Rivelin Robotics. While we have been delivering and installing Netshape Robots to key customers since last year, this project is a brilliant way to demonstrate the capabilities of Netshape across industries and applications,” commented Rivelin Robotics’ CEO Robert Bush.

Automated post processing of metal 3D printed parts

Metal 3D printed parts pose notable challenges when it comes to post-processing. Generally, metal supports are removed by hand once a part has been additively manufactured. This labor-intensive activity is time-consuming, messy, and can be dangerous.

Moreover, manual post-processing often results in poor repeatability and quality control, long lead times, and high costs. This is significant for companies working in regulated industries, such as aerospace and medical, that must adhere to strict manufacturing standards.

Rivelin Robotics seeks to overcome these challenges through its Netshape Robots. Launched at Formnext 2022, this technology incorporates the company’s Netshape software to enable automated support removal and surface finishing of metal parts. According to Rivelin, its technology enables a 90% reduction in defects, a 10-fold reduction in operating costs, and eliminates the potential for human risk and variability.

Innovate UK’s Project CAMPFIRE

Through Project CAMPFIRE, GKN Aerospace has adopted Rivelin Robotics automated post-processing technology. According to the British aerospace manufacturer, the finishing stage remains a barrier to its productivity and quality assurance when producing high volumes of parts.

Based out of its Global Technology Centre in Bristol, GKN Aerospace has already collaborated through Innovate UK’s ATI DAM and ATI Horizon R&D projects to develop the UK’s additive manufacturing capabilities. Now the firm is working to optimize the post processing stage of its metal 3D printing workflow with Netshape technology.

Through the collaboration, GKN Aerospace will assess the performance of Rivelin’s current system for the removal of support material from complex aerospace components. The company will provide direct feedback on upgrades and modifications that can be incorporated into future models.

“This will ensure that the technology has a route to scalable adoption in the aerospace sector, meeting the needs of end-users,” explained Brad Hughes, Principal Research Engineer – Additive Manufacturing at GKN Aerospace. “The upgrades will be validated by the consortium, through a joint technology demonstrator enabling us to quantify the benefits of the technology against the rudimentary manual removal methods.”

Away from aerospace applications, Project CAMPFIRE also sees Materials Solutions adopt Rivelin Robotics technology to assess its value for 3D printed gas turbines in the energy sector. According to Trevor Illston, Chief Manufacturing Engineer at Materials Solutions, additive manufacturing allows for the production of complex and optimized geometries that optimize the performance of these parts.

The company now hopes to streamline its post-processing operations to improve efficiency and enable time-savings. Materials Solutions will leverage a Netshape Robot to reduce the number of iterations in its process chain and improve the quality of the vane leading edges of its 3D printed turbines. This will remove the need for rework, boosting productivity. The firm will also work to determine whether Rivelin’s offering can meet the demanding certification requirements of parts for the energy sector.

Attenborough Medical, a UK manufacturer of medical devices, will incorporate Netshape Robots into its existing workflow of 10 large format 3D printers and two Nikon SLM Solutions laser sintering systems. The company uses this technology to produce patient-specific implants but faces bottlenecks when it comes to post-processing. These include long lead times and parts breaking during support removal.

“As our business has grown and volumes continue to increase, finding a solution to overcoming this bottleneck is imperative,” stated Ed Attenborough, the company’s CEO. “Being part of Project CAMPFIRE is a no-brainer and potentially a game-changer for us. We are working collaboratively within this project because we need a full digital post processing solution.”

Optimizing 3D printing post processing

Automating the finishing of 3D printed parts is nothing new. Previously, HP and AM Solutions, the Italian 3D printing subsidiary of the Rösler Group, collaborated to develop automated post-processing systems for Multi Jet Fusion 3D printers. Announced at Formnect 2019, this partnership saw AM Solutions add the HP Jet Fusion 5200 3D printer to its services portfolio.

In an interview with 3D Printing Industry David Soldan, AM Solutions Head of 3D post-processing technology, explained that the company focuses on 2-in-1 solutions that reduce costs and streamline the process chain.

This ethos is evident in AM Solutions’ C2 machine for polymer parts produced on the SLS and MJF powder bed processes. The C2’s Liquid Color Smoothing process can smooth and dye parts in a single pass, reducing the cost per finished part and cutting process times.

In the metal 3D printing space, Austrian company M&H recently adopted post-processing systems manufacturer Solukon’s SFM-AT1000-S depowdering system to improve the de-powdering and post-processing of its 3D printed metal parts.

The SFM-AT1000-S is designed to eliminate powder residues from the internal channels and cavities of complex parts. The system can also be used with Large and heavy metal components, reaching heights of up to 1,000 mm and weighing a maximum of 800 kg. Incorporating this system into its workflow, M&H aims to establish new benchmarks in post-processing across a range of materials including titanium, aluminum, stainless steel, Scalmalloy, and Inconel.

Want to help select the winners of the 2024 3D Printing Industry Awards? Join the Expert Committee today.

What does the future of 3D printing hold?

What near-term 3D printing trends have been highlighted by industry experts?

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news.

You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

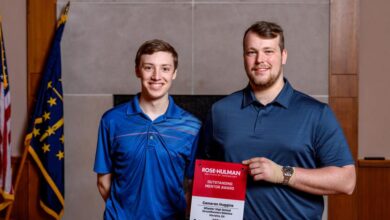

Featured image shows the Project CAMPFIRE team. Photo via Rivelin Robotics.