This robot will clean your home and do your laundry

Several companies

are now working on creating human-like robots that will enter the workplace.

One of these

companies is Norwegian 1X.

It was founded as

Halodi Robotics in 2014 by Bernt Øivind Børnich.

The company aim to build humanoid robots that can work side by side with humans to meet the

world’s labour demands.

1X is now making

two robots that resemble humans.

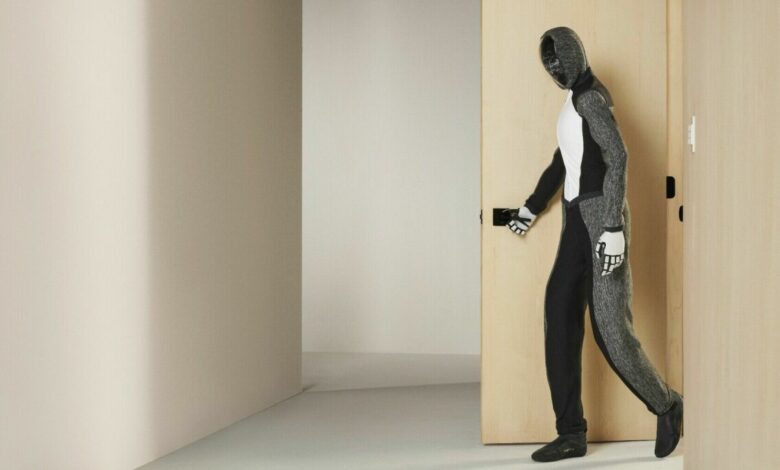

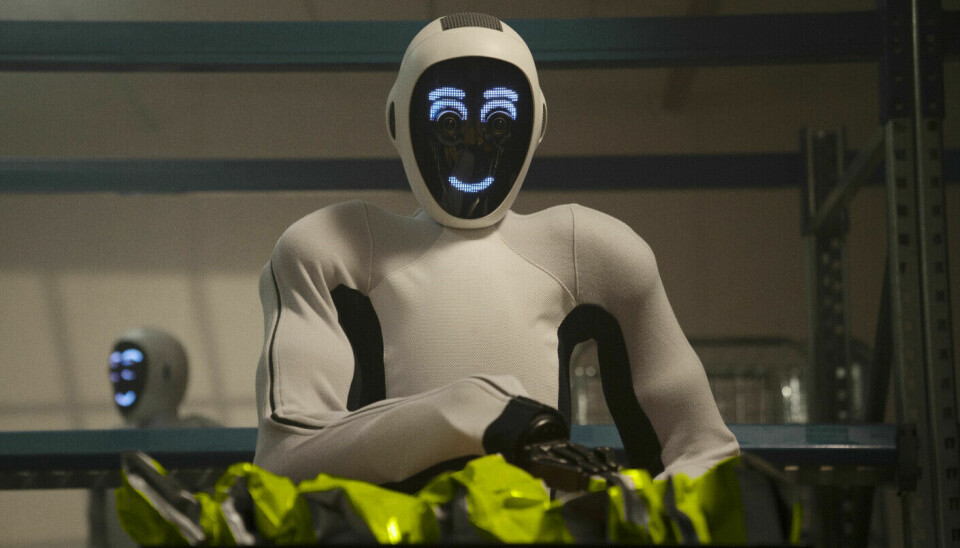

EVE and NEO

EVE is a robot that

has wheels and hands that can grip. It can open doors, operate elevators, and

move or lift things.

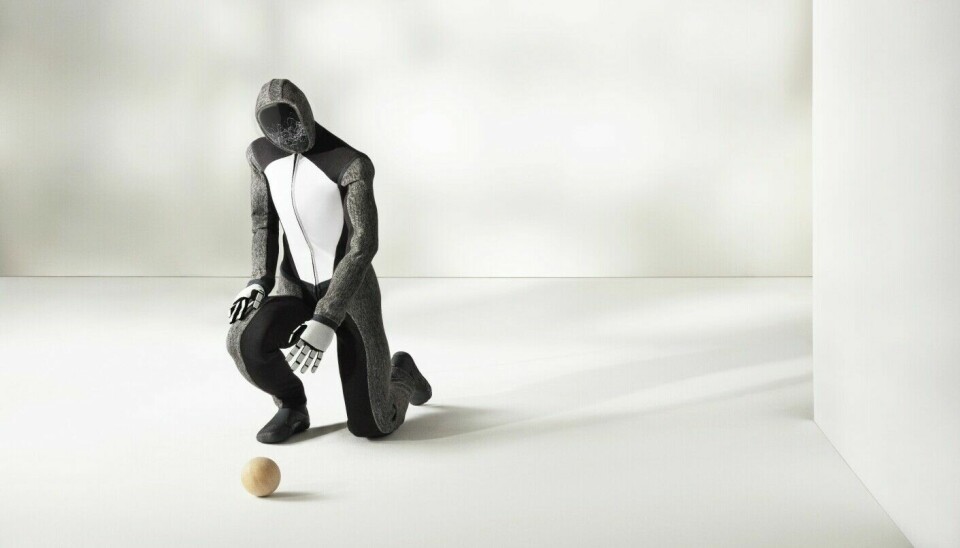

NEO looks even more

like a human and is under development. The goal is for people to be able to

talk to the robot and ask it to do things. The robot can walk, jog, and climb

stairs, according to 1X. NEO should be able to do tasks at home or handle work in

a factory.

1X plans to launch

NEO for home use next year, according to Bernt Øivind Børnich, CEO and founder

of the company.

Can log in and feed the cat

EVE is already at

work and has matured, says Børnich.

“It’s out with

several customers and performs tasks every day. It’s a commercialised product. Our

fleet size is getting quite large,” he says.

1X has produced 75

EVE robots, and half of them are used outside of the company by customers. Its

users include customers in the air, space, and logistics industries.

EVE is used in

three and a half ways, according to the 1X CEO.

The half range of

use is more like an experiment. Børnich naturally has an EVE robot at home and

has set it to do things around the house.

“But that’s not

really something we do with EVE, because it’s a bit too big and heavy,” he says.

NEO will be better

suited as a home helper.

The robots can also

be controlled via a VR headset.

“If I’m at my

cabin, I can log in and feed the cat or accept a package delivery at the door,”

he says.

Guards large buildings

EVE’s main area of

use is in security. The robot works as a security guard in large buildings. It

drives around on its own and checks to make sure everything is as it should be.

An operator monitors the EVE robots. If something needs to be resolved, the operator can control EVE

via a VR headset.

“Usually, these

situations are very simple. For example, a door alarm has gone off. The

operator takes over and sees, for instance, that someone has put a shoe in the

door. Then you can get EVE to bend down, remove the shoe, and close the door,”

Børnich says.

Other examples of

what EVE might need to tackle include closing windows that people have

forgotten to close or to turn off a coffee machine.

“Instead of making all these rounds, you can look at a fleet of robots that provide a very good

overview of the building. You can solve problems as they arise,” he says.

At the testing stage

EVE is the only

humanoid robot that Børnich knows of that is currently being purchased by

customers.

“We’re no longer

in the pilot stage,” he says.

Other humanoid

robots are often tested via the company’s research and development budget.

At this stage, EVE

is being perfected for merchandise and warehouse work.

“It’s going really well. We’re not far from commercial deliveries. But there’s still some way to go,” he says.

The competition is

fierce. People who do the same thing for eight hours every day are quick at

completing their tasks, Børnich says.

The last area of

use will be in production and car manufacturing. This is even more challenging because you cannot fail, Børnich notes. However, he believes the company can enter

this market in two to three years.

How can robots understand new tasks?

1X is working on

developing the artificial intelligence of the robots. EVE functions largely

autonomously, controlling itself. Humans can take over when necessary.

1X is working on

teaching EVE new things based on a few demonstrations of the task, as well as data previously collected and large models they have trained.

You can ask

generative artificial intelligence to draw an avocado chair, even if the model

has never seen it before.

“In robotics, we

haven’t yet been able to get robots to do tasks they have never seen before and

have never been trained for,” says Børnich.

“What’s very

exciting is that we see that we are getting this to work. That’s the next priority.”

Will be controlled in the beginning

1X plans to launch

NEO for home use as early as next year in the San Francisco area.

“At this beginning

stage, this product is quite limited. It will be aimed

at those who are very interested in technology and who find it acceptable that the product takes some time to mature,” says Børnich.

One advantage of

sending the robots out into the world early is that the experiences provide a

lot of data. This helps to make the robots more intelligent and better at solving

tasks over time.

In the first year, 1X

operators will control the robots.

“The aim is to move

towards autonomy as quickly as possible,” Børnich says.

Privacy concerns

are also something 1X is working on, he adds.

1X envisions NEO to

be able to do things like tidy up, washing, and laundry. It will also be able to

entertain and be someone to talk to. It can display body language.

Looking forward to seeing what people come up with

1X wants people to

be able to take part in training the robots themselves and collaborate with

others.

“You should have

something to look forward to every day when you come home, to see what others have

come up with. You can download others’ upgrades for lots of fun things

to do,” Børnich says.

Perhaps someone wants to teach NEO to dance or be a workout partner.

“I’m really looking

forward to seeing what people will come up with. Of course, there will be control from our side to ensure that what people teach them is sensible and safe,” he says.

1X is currently building a factory that will

produce NEO robots. They will produce more NEO robots than EVE robots.

“We’ll see a big increase

in production volumes,” says Børnich.

Collecting vast amounts of data

We have seen humanoid

robots do many different things for years without them appearing in people’s

living rooms. Is there anything different now?

Børnich believes

two things have changed.

“One is that I

believe we are now in a position to solve the AI problem,” he says.

“The models we use

in robotics are not that different from large language models or those used to

create videos, like Sora.”

They are trained on

huge amounts of text, images, and videos that already exist on the internet.

It is not as easy to get the same amount of data for robotics, as there is no existing data for physical task-solving. It must be gathered anew.

“That’s the current challenge,” Børnich.

Out and about

The company has several

strategies to address that problem. 1X plans to build many robots quickly and

collect data when the robots are physically out in environments, doing things

and collecting data from sensors. This is called embodied data.

The fact that the

robots will be used in different place – at home, in factories, or in warehouses – is an advantage, according to Børnich.

“There’s a limit

to how much you can learn from packing the same box of shoes every

day. Once you’ve done it 200 times, there’s not much more to learn. You have to

go out into different environments to learn more,” he says.

Others are focusing on using more videos, for example.

“I can’t prove

that you need a body and embodied data to solve general artificial

intelligence. But as an engineer, I can say that it’s cumbersome not to have

it,” he says.

“Contact forces,

for example, are not directly observable in a video. It’s a bit like trying to teach a language model colours without pictures. It works,

but you need a lot of examples in language to understand colours.”

Creating robots

that are so intelligent that they can work among us requires an

internet-scale amount of data, according to Børnich.

Technological advances

The second thing

that is different now is that it is possible to build robots that are safe and can be produced at a reasonable price, according to Børnich.

NEO is lightweight

and has a soft exterior. Motors pull strings, loosely inspired by muscles.

“This gives the robot dynamic movements, making it safe to have in the house and when

it bumps into things,” he says.

Over the years,

there has been a lot of research on making motors for robots and how to

transfer power, as well as developments in sensors.

“There’s also been significant progress in AI and simulations. We use this a lot when designing components,”

he says.

Børnich believes

that it won’t be that long before humanoid robots enter workplaces.

“It will happen.

First slowly, then faster than most people might think,” he says.

For people in the industry, it’s clear that the development is gradual, but for the rest of society, it could seem like it is

happening a little too quickly, like with ChatGPT, he thinks.

———

Translated by Nancy Bazilchuk

Read the Norwegian version of this article at forskning.no