3 takes on MRO data analytics

Data analytics in maintenance often comes down to three metrics:

- How often does that (conveyor, lift truck, automated storage system or other essential materials handling piece of equipment) require maintenance?

- What’s the next date for scheduled maintenance?

- How much did you spend last year?

Yes, you probably have your own top three list. But it’s still a top three list. There has to be a better way to manage MRO.

And there is. However, at least 75% of materials handling operations have not started their transition to a more sophisticated data analytics program.

That said, it was time for Modern to talk to some experts about where MRO data analytics stands today and some options going forward. So, we talked to automated systems supplier Dematic, lift truck supplier Raymond and MRO services provider SDI.

Each has its own take on MRO data analytics. That should tell you something important right away. Quite simply, there is no right or wrong way to approach this can of worms.

Furthermore, all recognize that we are in the early days. They and others will refine, modify even overhaul their approach to data analytics going forward as they learn more and technology changes. Slipping in a quick mention of AI at this point is not gratuitous. Just an affirmation of the inevitable.

Here’s what the three had to say midway through 2024.

Automated systems perspective

A tech uses data and expertise to make specific maintenance decisions.

Mike Jones, implementation and support manager, Dematic

Joe Ellenwood, resident maintenance manager, Dematic

If there’s a recurring word in Dematic’s approach, it has to be data. The data that gets collected; where that data is sent; and how the data is analyzed. And, ultimately, how that data is turned into information that generates work orders that address maintenance issues.

“Good data is essential to generating accurate information that solves maintenance problems. Data is the foundation,” explains Jones.

Foundational to making data actionable is Dematic’s Sprocket enterprise asset management software (EAM). Jones was the general manager of Sprocket before Dematic purchased it in 2013.

“The software streamlines and automates processes to assist in maintenance management, improves workflow within maintenance departments and minimizes costs to perform maintenance,” says Jones.

The software is hosted on the Google Cloud Platform. It’s also one of several such software platforms for EAM.

That said, the techs who ultimately make the maintenance decisions are very much in the loop, explains Ellenwood. As the manager of Dematic’s resident maintenance program, Ellenwood puts a heavy emphasis on the value of each tech’s experience with both the equipment and the output from Sprocket.

“We’re only in the very early stages of taking input from the software and letting it direct what the techs actually do,” Ellenwood continues. He estimates it will be several years before the balance of power between software and human techs shifts from the latter to the former.

“We rely on techs to absorb data both from Sprocket and their familiarity with the equipment itself to make specific maintenance decisions,” Ellenwood says.

He also points out that Dematic does not have a centralized war room that manages maintenance for clients. Instead, the software can be run either by the client on site with or without Dematic techs, or by Dematic on site with Dematic techs.

One of the strengths of maintenance software right now, says Jones, is its ability to display for techs the trends week to week. “It’s important to look at past failures and draw a trendline that previously would not have been possible to see,” explains Jones.

When asked about the top 10 reports, which he labels anticipatory, Jones identified these:

- Mean time between failure,

- Mean time to repair,

- Preventive maintenance compliance,

- Preventive maintenance forecasting,

- Labor utilization,

- Spare parts inventory,

- Spare parts usage,

- Down time reporting,

- Infant mortality time to failure by part, and

- Corrective work order generation.

“These metrics offer insights at levels that were not generally visible previously,” says Jones.

Clearly, MRO data analytics has a way to go, agree Ellenwood and Jones. And when asked about the future of AI, they say it will come to materials handling equipment maintenance but only long after it has established itself in process industries.

Lift trucks perspective

About 25% of companies use data analytics to guide lift truck fleet maintenance

Tillie Battaglini, product manager, Raymond

Dave Norton, vice president of customer solutions and support, Raymond

Talk to Battaglini and Norton about MRO data analytics, and it quickly becomes clear that this is complicated. And in one major regard, lift truck maintenance already has a leg up when paired with telematics data from trucks today.

While standard telematics capabilities provide data relative to access control and utilization levels, layering MRO data to this allows for deeper analysis and understanding of equipment usage.

As Battaglini points out, there is nothing unusual about collecting data with standard onboard telematics capabilities. These monitor and track lift truck usage from access control to activities and utilization levels.

Then iTrack asset maintenance software, which she lives with day-in and day-out, provides that data to several outlets. These range from a web-based interface available to lift truck users, Raymond dealers, techs and Raymond itself.

The next question is: What to do with the data, explains Norton.

“Even for the most analytical of users, this requires some navigation to take the data and put it to good use. It can all be quite confusing for people,” says Norton.

Ask him to estimate how users respond, he has this to say.

“About 25% know what they are doing and do use data analytics effectively to manage their fleet. Another 50% are infrequent users. And the final 25% would be OK if it all just went away,” says Norton.

The only trouble is MRO data analytics “are critical to running the business,” adds Norton.

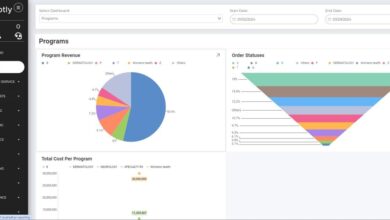

Battaglini says these are the top 10 uses for asset maintenance software:

- Total cost of maintenance by site,

- Recommendations for retaining, removing, reallocating and replacing assets,

- Asset profile from last work performed date to days of service,

- Fleet availability by individual asset,

- Dispatch metrics from request-to-dispatch time to total asset downtime,

- Total maintenance for the fleet,

- Parts usage by frequency,

- Rolling comparison for managing to budgets,

- Cost per hour to operate, and

- Customer service order review to provide oversight and control of work orders.

And while that list is all about data, people are key, says Norton.

“This isn’t just data. This is data that needs to be analyzed and interpreted by people. And I’m not talking about a team of highly trained analysts. MRO data analytics needs people who can look at the data, go out to the floor and talk to operators and make maintenance decisions,” says Norton.

And still no mention of AI. Yet. Battaglini and Norton agree that AI will have a future role. But for right now, smart people who can interpret data are where the answers rest.

The MRO services provider perspective

Parts usage by frequency is a core metric.

John Delligatti, director of digital supply chain transformation, SDI

Like others interviewed for this story, Delligatti will tell you MRO data analytics is all about the data. But he also says there’s another essential element—data literacy.

This is where he shifts the emphasis to the analytics. And, yes, he was able to pull in a sports analogy. Better yet, it works.

“Fantasy football is a data game,” says Delligatti. “And its data is expressed as touchdowns and yards. MRO data analytics is fantasy football with the data expressed as availability and costs.”

Now that we have established, what exactly does it mean?

“People have to able to understand the data that’s collected and translate it into business outcomes. They have to understand what the data is trying to tell them. For instance, a stock out in a critical spare part is vastly different than a general stock out. They are not the same event. And people need to understand that and act on it accordingly,” Delligatti says.

He adds that people need to interpret and consume data. However, and this is a big however, those people need not be highly trained data scientists. In fact, it’s better for all if those people are not involved. Instead, people just need to be data literate. Unfortunately, Delligatti says only about 25% of the people he comes across are data literate.

To help everyone, SDI has published an electronic guide “Zeus Supply Chain Analytics Guidebook.” Key topics covered include key metrics in MRO as well as spare parts procurement and management.

Delligatti says it’s all about data-driven decision making. And key areas here are all about doing more with less, pricing, lead time and parts availability.

In other words, MRO data analytics goes beyond the techs and the decisions they make from data. “The costs and lead times of MRO spare parts are still critical and that is not becoming any less important,” says Delligatti.

Looking to the future, he says that AI will be part of the MRO data analytics equation. And it will only amplify the importance of good data up front.

But the emergence of AI is still some time off. Delligatti estimates that less than 5% of companies are ready. And to him “ready” means of a mind set to spend for AI and capable of enterprise-wide analytics. But at least we know AI is coming to MRO data analytics.