Report Outlines Use of Generative AI and Digital Twins in Manufacturing

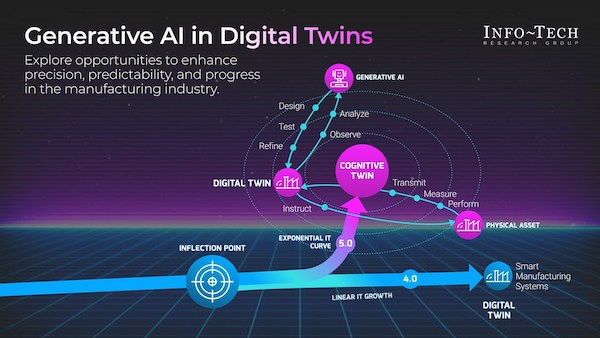

Info-Tech Research Group has released a new resource report that outlines strategies for manufacturers to leverage generative artifical intelligence (Gen AI) and digital twins to enhance precision, predictability, and progress in manufacturing.

“Digital twins have long been recognized for their potential to revolutionize predictive maintenance and streamline processes. When combined with Gen AI, the possibilities for the manufacturing industry expand exponentially,” says Shreyas Shukla, principal research director at Info-Tech Research Group. “However, many manufacturers worldwide continue to grapple with the challenges of Industry 4.0 and the remnants of pandemic-era supply chain disruptions. The fusion of Gen AI and digital twins promises not only to optimize current manufacturing processes but also to usher in a new era of design, simulation, and real-time predictive analysis.”

Info-Tech’s research identifies several obstacles facing the manufacturing sector, including the significant compatibility of integrating new technologies with existing systems. According to the report, there is a lack of skilled professionals who are well-versed in both the manufacturing industry and advanced technologies, including AI. Moreover, there is a need for a comprehensive understanding and ethical use of Gen AI to ensure integrity in decision-making processes within manufacturing operations.

According to Info-Tech’s research, cognitive twins play an important role in the modern adaptive cognitive manufacturing system (ACMS) paradigm. ACMS is different from other modern manufacturing paradigms, such as Industry 4.0, and is primarily focused on intelligent collaboration between humans, IT, and OT.

The firm’s blueprint names some of the strategic advantages of harnessing exponential IT technologies like Gen AI and digital twins across the manufacturing industry. Those advantages are:

- Enhanced Analytics: Predict future states of the system and identify potential issues or failures.

- Optimized Performance: Optimize system and process performance, resulting in improvements.

- Improved Decision-Making: Create innovative designs and solutions, resulting in novel products and services.

- Improved Resilience: Enhance supply chain visibility and predict potential disruptions.

- Improved Modeling: Create accurate simulations of complex systems, thus quickly developing and testing new concepts.

- Risk Management: Assess and simulate various risk scenarios, thus enabling proactive risk management.

- Rapid Changes: Enable digital twins to adapt in real-time to environmental changes.

- Sustainability and Waste Reduction: Reduce waste and energy consumption, leading to more sustainable operations.

In the blueprint, Info-Tech underscores the significant role AI is expected to play in manufacturing over the next decade, potentially outpacing the impact of automation in the past. The firm suggests that organizations prioritizing AI investments now can significantly expand their offerings and capabilities, leading to increased market presence, revenue growth, and improved customer satisfaction.

Sources: Press materials received from the company and additional information gleaned from the company’s website.