ABB launches the special robot controller Omnicore

Commander

ABB launches the special robot controller Omnicore

Source:

ABB | Translated by AI

Related Vendor

ABB Robotics has developed Omnicore, an “intelligent” automation platform that is faster, more accurate, and more sustainable to optimize and future-proof robot operations.

(Image: ABB)

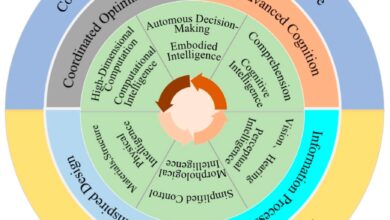

The Omnicore platform is the result of an ABB investment of over 170 million US dollars in next-generation robotics. It marks a major step towards a modular and future-proof control architecture for robot systems. Omnicore enables complete integration of artificial intelligence, sensor, cloud and edge computing systems to develop cutting-edge and autonomous robot applications. The reason is that automation is a strategic necessity for ABB customers who demand more flexibility, simplicity and efficiency in order to respond to global megatrends such as labor shortages, uncertainty, and the need for sustainable economic practices. A unique feature of Omnicore is its ability to control movements, sensors and application devices through a single integrated system. Last but not least, ABB celebrates 50 years of innovation history, as noted.

Robots now work significantly faster and more economically

Through the development of advanced mechatronics, AI, and image processing systems, ABB robots are more accessible, powerful, flexible, and mobile than ever before. Increasingly, however, they also need to work seamlessly together – both with ABB and with each other – to perform more tasks in more places. That’s why ABB is launching Omnicore. It is a unique, unified control architecture based on a single platform and language, and includes ABB’s entire portfolio of leading-edge hardware and software. The special Omnicore motion control achieves a robot path accuracy of less than 0.6 millimeters in the field, which is achieved even when multiple robots are working at high speeds of up to 1,600 millimeters per second. This opens up new automation possibilities in areas like arc welding, mobile phone display assembly, adhesive bonding and laser cutting, where high precision is required, as ABB explains. Compared to the previous ABB controller, Omnicore enables up to 25 percent faster robot operation and a 20 percent lower energy consumption, it is said.

Unlimited robot possibilities for value creation

Omnicore is based on a scalable, modular control architecture that offers a wide range of functions for developing almost any conceivable application. It opens the door to ABB Robotics’ entire hardware and software portfolio – in any combination and on a single control platform. This creates unlimited possibilities and new ways of creating value. Therefore, Omnicore is suitable for any company wanting to automate processes in existing and new segments such as biotechnology, construction, or many other industries. With over 1,000 hardware and software functions, one can easily plan, execute, maintain, and optimize operational processes, as promised by ABB. This is made possible by ABB software features such as Absolute Accuracy and Pickmaster Twin, as well as hardware options ranging from external axes and imaging systems to field buses, as noted by ABB. For example, in terms of the automotive industry, Omnicore allows for an increase in production output of robot-supported press lines from 12 to 15 strokes per minute, thus producing 900 parts per hour, giving manufacturers a tremendous competitive advantage.