Robotics: Evolution and the dawn of new opportunities

The Transformative World of Robotics

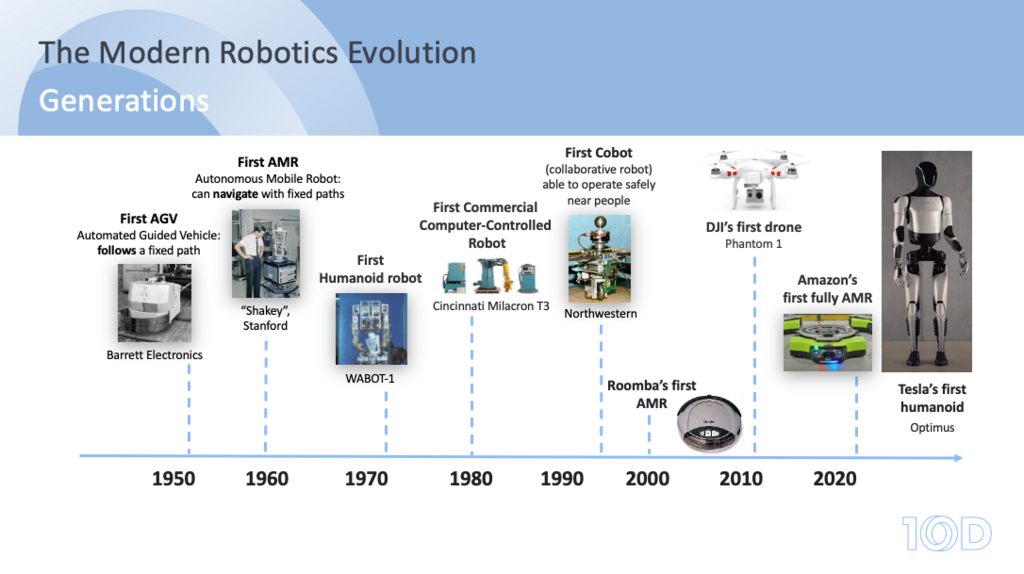

Robotics stands as a cornerstone of technological innovation, merging mechanical, electrical, and software engineering to create machines that can assist, augment, or automate human activities.

This field is rapidly evolving, propelled by advancements in AI, machine learning, and hardware, making robots more intelligent, versatile, and efficient in times of ever-increasing demand. As these machines grow in capability, they increasingly impact every sector, from manufacturing and healthcare to agriculture and personal care, reshaping productivity and efficiency paradigms.

Opportunities for Innovation and Investment

The assessment of robotics-related opportunities should be performed, in our opinion, at the industry level: we look for robots that have the potential to significantly disrupt a specific industry by reducing overall workload and increasing effectiveness and efficiency. There are sub-categories of robotics technologies (e.g. task-specific robotics, general-purpose robotics, software-only solutions, etc), however, in this blog post, we have decided to address the industry need and readiness for robotics, including the pain point/unmet need as well as other drivers of adoption (such as level of sophistication of the customers, willingness to pay, willingness to adopt such technologies, etc.).

Examples of industries with high potential robotics disruption include:

1. Healthcare: the medical industry is known for its adoption of highly sophisticated tech that can lead to better patient outcomes and lower cost of care, despite a high upfront cost in some cases. As such, it appears to be a good candidate to adopt robotics solutions. Examples of applications include:

-

Surgery: robotics technologies enable precise and minimally invasive procedures and surgeries (including remote), leading to reduced recovery times and improved patient outcomes.

-

Diagnostics: the implementation of robotic automation to diagnostics workflows such as imagery and laboratory testing can lead to faster and more accurate diagnostics results.

-

Rehabilitation: robotics applications such as prosthetics (e.g. bionic limbs) and advanced software can assist patients with mobility impairments, enhancing their quality of life, regaining sensory feedback, and speeding up recovery. One example of application in this domain is OneStep, a company that leverages smartphone sensors to continuously analyze real-life motion, enabling the convergence of smart prosthetics and advanced software to tackle motion-related challenges and rehabilitation.

2. Manufacturing: traditionally, there is a high willingness to invest in robotics and automation tech in the manufacturing industry (for example, in the automotive sector) as it continuously seeks to find new ways to increase production efficiency, quality control, and operation. The return on investment (ROI) is typically very clear, and is driven primarily by labor cost reduction, increased production efficiency, and higher product quality.

Robots can perform repetitive tasks with high precision and consistency, leading to increased production efficiency and reduced error margins. Unlike human workers, robots can work 24/7, significantly boosting productivity. Specifically, robots have proven successful at performing the following tasks:

-

Assembly: robots can assemble complex products with extreme precision, such as electronic components, where small errors can lead to significant production issues and associated cost burdens. They can also assemble very large components, that are difficult for humans to handle (e.g. automotive components).

-

Inspection: robots equipped with advanced sensors and AI can conduct thorough inspections of products, ensuring high-quality standards.

-

Hazardous materials handling: robots can safely handle and process hazardous materials, such as chemicals or radioactive substances, and operate in extreme conditions (e.g. high temperatures, toxic substances), significantly reducing the risk for human workers and ensuring continuous production in challenging environments.

3. Defense: while the defense sector seeks highly sophisticated products and allocates significant investment to R&D, it has also been challenging for governments to stay at the forefront of technological advancements, especially given the large investments in private defense companies and their high pace of development. We observe a trend that consists of “militarizing” commercial technologies, which opens doors for new players in the industry. While sale cycles might be longer (18-24 months) than in other industries, the budget and therefore market potential is however substantial.

-

Surveillance and reconnaissance: robots such as drones and autonomous vehicles can be deployed for surveillance and reconnaissance missions, providing real-time data, and reducing the risk to human soldiers. In addition, robotic systems can enhance national security by monitoring borders (e.g. detecting intrusions).

-

Combat and support: robots can minimize human casualties and increase the precision of military actions by engaging in combat operations, for example by neutralizing explosives and handling complex rescue missions. Robots can also ensure safe and efficient logistics and delivery in hostile environments (e.g. transporting equipment and supplies).

Robotics is a very rapidly evolving field, and as such comes with several risks that may impact the development, commercialization, and adoption of the technology:

-

Regulatory and Compliance Risk: the deployment of robotics in certain industries may be subject to regulatory scrutiny and compliance requirements, such as healthcare. Robotic systems also pose specific cybersecurity and data privacy threats that need to be managed.

-

Safety and Cost of Error: some industries, such as healthcare (e.g. high-precision surgeries) and manufacturing (handling hazardous materials) entail a safety risk factor. The cost of error might be tremendous, and we may not accept the error margin of human mistakes for a robot. This discussion is parallel to the one regarding Autonomous Vehicles.

-

Market Demand and Adoption Risk: the market demand for robotics solutions may vary across industries and regions, and factors such as economic conditions, competitive pressures, and customer preferences can influence adoption rates.

-

Competition and Disruption Risk: partially driven by increasingly many new entrants and an opaque innovation strategy/R&D roadmap of key tech players, we’re seeing an intense competitive dynamic with players who are competing on similar use cases using different technologies or approaches.

-

Ethical and Social Implications: lastly, it is worth raising the ethical and social considerations related to matters such as autonomous decision-making, potential job displacement, security, privacy and surveillance, creativity/IP generation, and human-robot interactions.

In conclusion, the robotics industry stands on the verge of a significant transformation driven by advancements in technology, growing market acceptance, and economic feasibility. We believe it stands at a pivotal moment in terms of robotics capabilities and potentially widespread adoption.

While the commercial robotics market is still in its infancy, the potential effect of robotics on our lives, across all categories, is immense. They are expected to reduce workload, enhance safety, increase efficiency and effectiveness, and as such disrupt both the realm of possibilities (industry outputs) and change the role of humans in society.

The pomise of robotics in shaping the future across all verticals and applications is undeniable and calls for cross-domain collaboration. As we embark on this new era, we are eager to explore and support the disruptive potential of robotics across various functions and industries.

The writers are Itay Rand, Emmanuelle Lipski, and Adi Mashash from 10D