ANYbotics agrees partnership with Energy Robotics – Robotics & Automation News

ANYbotics, a provider of autonomous robotics solutions, and Energy Robotics, a developer of advanced AI-software platforms for autonomous robotics, have agreed a strategic partnership.

The companies say the collaboration will “transform asset monitoring through comprehensive end-to-end inspection solutions and data integration for the energy industry”.

The ANYbotics and Energy Robotics platform integration was recently successfully demonstrated in a leading international energy company’s program to scale automated robot inspections.

ANYbotics’ flagship robot, ANYmal, features AI-driven mobility, full autonomy, and capabilities for navigating complex industrial environments, performing routine inspections, and capturing critical data.

With over 100 robots delivered to customers worldwide and with an Ex-proof version of its robot, ANYbotics is well positioned for the energy industry.

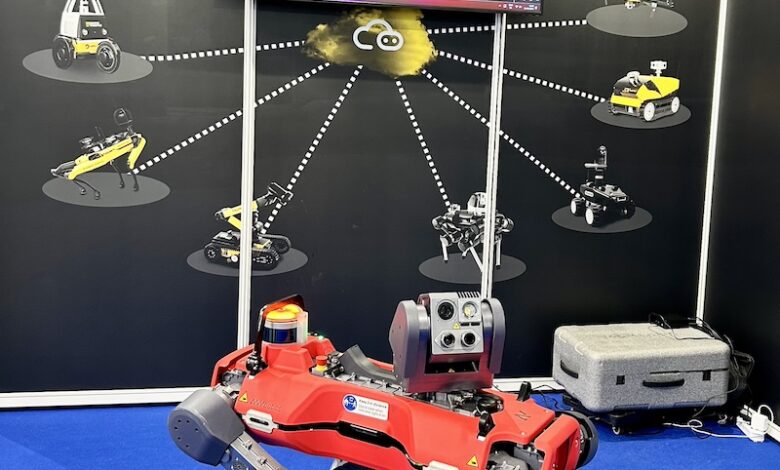

Energy Robotics’ hardware-agnostic fleet management solution is renowned for its robust data collection, processing, and analytics capabilities.

This platform enables seamless integration with various robotic systems, providing a comprehensive solution for data-driven decision-making and robot and drone inspection operations.

Dominik Neuwirth, VP partnerships AI, Energy Robotics, says: “We believe this partnership will set a new standard in autonomous robotics.

“Our AI-powered software platform for fleet management and analytics capabilities will complement ANYbotics’ unmatched robotic mobility and autonomy, providing significant value to the industry.”

ANYbotics offers a versatile API that integrates seamlessly with any third-party platform.

The integration with the Energy Robotics platform enables operators to manage their robot fleets directly from their existing asset management or digital twin software, streamlining operations and reducing the need for additional training or infrastructure investment.

The deep integration between the ANYbotics and Energy Robotics platforms accelerates the deployment of ANYmal for Energy Robotics’ customers and enables ANYbotics customers to leverage the Energy Robotics AI Software platform.

This will ensure faster implementation, an improved customer experience through easier adoption, and a wider market reach that enables broader access to advanced robotics technology.

This integration was recently successfully demonstrated in a leading international energy company’s program to scale automated robotic inspections.

The integration functionality included inspection data, camera streaming, planning and control of inspection missions, remote control (teleoperation), and monitoring via the Energy Robotics platform.

The unveiling of this collaboration at Achema 2024 is a significant step forward in autonomous robotics. The joint go-to-market strategy targets sectors where the need for autonomous solutions is paramount.

By integrating their technologies, ANYbotics and Energy Robotics will set a new benchmark for overcoming asset monitoring challenges such as hazardous environments, remote monitoring, and unplanned downtime.

This will further improve the energy industry’s safety, efficiency, and operational reliability. The combined strengths of the two companies will also foster more robust and versatile solutions.

Satschin Bansal, global VP strategic alliances and partnerships, ANYbotics, says: “The Energy Robotics partnership makes it easier for customers to integrate multiple inspection robots into their operations seamlessly.

“Additionally, it accelerates market penetration by leveraging both go-to-market teams.”

ANYbotics will be a preferred four-legged robotics partner of Energy Robotics, demonstrating its commitment to providing cutting-edge autonomous solutions for various industries.

As part of this alliance, the ANYmal robot will be deployed in the robot park at Energy Robotics’ headquarters in Darmstadt to demonstrate ANYmal’s advanced capabilities live to customers in real-life scenarios.