Robotic Arm for Porcelain Bushing Cleaning in Substations

A recent article published in the journal Scientific Reports demonstrates the design and development of a robotic arm for rinsing porcelain bushing in high-voltage substations. The researchers leveraged artificial intelligence and 5G technology to develop a robotic arm prototype with an integrated control system. Additionally, they verified the feasibility and effectiveness of the robotic arm in the Nanjing power grid.

Conventional Porcelain Bushing Cleaning

Porcelain bushing is a kind of insulator widely used in electrical substations as an essential part of external insulation. Contamination of porcelain bushing due to pollution can be dangerous for the corresponding electrical devices. It can cause flashovers, large-scale power failures, or even casualties. Thus, regular cleaning of porcelain bushing is crucial for the proper functioning of the substation.

Conventional cleaning of porcelain bushing is carried out manually with power shutdown and water or air blowing with power on. The manual cleaning is performed by the maintenance workers using a special cleaning cloth or brush. They are required to climb the electrical device or stand on a platform to complete the cleaning task. These methods have low efficiency and pose high security risks. Automatic cleaning devices like robots can overcome such challenges and improve cleaning efficiency and consistency without risking humans.

Design of Robotic Arm

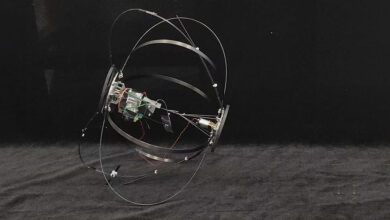

The researchers in the present study developed an automatic cleaning robot for 500 kV porcelain sleeves for power outage maintenance in substations. The main components of the robotic arm include a mobile electric lifting platform (supports the whole device), a cleaning brush finger, an operation box, a drive control box, photoelectric switches, and a lead screw module (for precise positioning). The operation box houses a control button box and industrial control touch screen, which control the platform and cleaning brush speed.

The cleaning brush finger is made of aluminum alloy and has a 120-degree split structure that allows easy adaptation to complex substation environments. It is driven by DC brushless motors with speed adjustable to the site conditions. Moreover, the cleaning brush rod is designed to have a variable axis length, which ensures efficiency and consistency in cleaning porcelain bushing.

Photoelectric switches help in precise localization of the mechanical arm and position perception of porcelain bushing. The positioning module ensures that the porcelain bushing is centered in the opening ring of the cleaning brush finger and prevents collision risk due to deviation of the porcelain bushing position. This open-cleaning circular ring structure of the device enables simple and effective alignment of the porcelain bushing during cleaning.

Control Method and Edge Computing

An efficient control system is crucial to realize the design of the robotic arm. Thus, the researchers used an S7-200 programmable logic controller (PLC) as the control unit of the whole cleaning robotic arm, which controls its every action by processing sensor signals. A real-time angle-feedback control method is applied for automatic platform leveling. It also ensures that the cleaning brush finger does not collide with the porcelain sleeve during platform balancing. The speed and torque sensor data are collected by an intelligent maintenance terminal and sent back to the monitoring system using a 5G network.

After positioning the robotic arm, it is crucial to maintain it at a safe distance from the electrical devices in the substation during the cleaning process. The researchers used edge computing to design safe-distance control and location methods based on ultra-wideband technology. Integration of Internet-of-Things and edge computing allows small-scale definition of the arm’s working area. It isolates the charged area near the work site and keeps the equipment and personnel safe during the insulator cleaning.

Field Test

To demonstrate the on-site applicability of the proposed automatic insulator cleaning, a prototype of the robotic arm was developed as per the porcelain structure of a typical 220 kV circuit breaker in a 500 kV substation. This prototype was employed for a cleaning test in the Nanjing power grid after preliminary commissioning in the laboratory and its performance was thoroughly evaluated.

The platform balancing adjustments were completed within 0.5 seconds according to the established control strategy. Once the robotic arm reaches the designated position, cleaning starts automatically. A 4.8 meter long 500 kV porcelain bushing was cleaned in 30 seconds, and the total cleaning time starting from the initial positioning was 50 to 105 seconds, which is much more efficient than manual cleaning methods. Thus, the robotic arm successfully passed the field test.

Significance of the Work

The robotic arm developed in this work can efficiently rinse porcelain bushings andtransmit all the corresponding information using 5G technology for feedback. Its effectiveness, quality, and safety were verified by the field test at the Nanjing power grid, where it not only met the main performance goals but also exceeded design expectations.

In conclusion, the devised intelligent porcelain bushing cleaning robotic arm can be used to maintain electrical devices in high-voltage substations and as a measure against pollution flashover of porcelain bushing. This study widens the applicability of robots in cleaning insulators and enhances the state control level of substation equipment.

Journal Reference

Chen, H., Han, W., Xu, W., Tang, Z., Chen, Y., Xu, P., & Ma, Z. (2024). Design of robotic arm for the porcelain bushing in substation. Scientific Reports, 14(1). https://doi.org/10.1038/s41598-024-58443-7, https://www.nature.com/articles/s41598-024-58443-7