ABB robots help quartz plant cut cycle times by 80%

|

Listen to this article |

America Quartz Technology (AQT) specializes in the manufacturing and processing of formed quartz products for the electronics and semiconductor industries at its plant in Hue, Vietnam. The production of AQT’s products demands the highest level of meticulousness and accuracy.

Challenges

Previously, components were processed manually, with workers performing high temperature heating processes. This dangerous and repetitive work meant that staff turnover was high, with an increased risk of accidents. There was also the risk of errors that could lead to serious production losses.

To solve these challenges, AQT decided it needed robots that would avoid labor shortages, reduce risk and improve productivity.

Solution

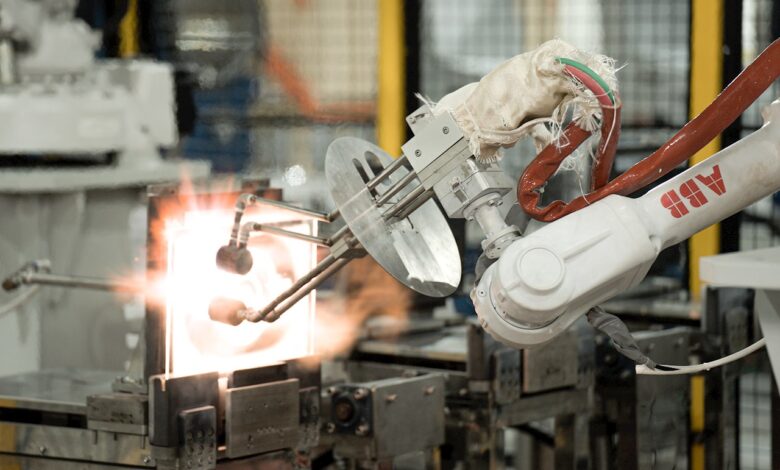

Having used ABB robots at its plants in the U.S., AQT approached ABB for a solution for its Hue plant. The result is a robot production cell consisting of an ABB IRB4600 industrial robot, an IRB2600 industrial robot and a moulding machine.

The ABB IRB4600 picks up the quartz workpiece and places it into position for the heat treatment process. Following this, the IRB2600 robot heats the workpiece evenly. Then, the cylinder mechanism sucks the heated quartz plate into the mould and shapes it. After 30 seconds, the vacuum valve shuts off, and the IRB 4600 robot removes the product and repeats the cycle.

![]()

Results

Since the introduction of the robots, plant efficiency and performance has been significantly improved, with five times fewer defective products due to production errors.

“Using the solution provided by ABB, our products are now consistently completed to the highest quality, with less manual intervention required and a reduction in errors. Conditions have also improved for workers as all of the dangerous and repetitive work is now taken care of by the robots,” said Tran Phuoc Thanh Vu, factory manager, America Quartz Technology.

Another improvement has been a dramatic reduction in production cycle times. With the robotic process, production time has been reduced from 25 to just five minutes, with a current average output of 100 pieces a day, a four-fold increase on the previous manually-based production process.

“The solution brings enormous value to the plant – it improves production capacity, ensures on time delivery of customer orders and offers high stability during the production process,“ said Vu. “We always aim to have a modern and professional factory, using the latest techniques and technologies to achieve a lean production process and improve productivity. Our good experience with ABB robots means that we plan to invest in several robot stations for the plant in the coming year.”