ADLINK’s one-stop solution elevates AI-innovations in electric vehicle battery manufacturing

Ensuring the quality and efficiency of batteries is crucial for the performance and safety of electric vehicles (EVs). With this in mind, most new energy EV battery manufacturers are actively advancing towards smart technologies, integrating motion control, visual inspection, and other technologies into the initial, middle, and final stages of the manufacturing process.

For instance, a leading automotive battery manufacturer has recognized that traditional manual sampling inspections are not only time-consuming and labor-intensive but also tend to identify defects late in the process. This results in the production of defective products and increased waste.

In due course, the manufacturer entrusted a specialized System Integrator (SI) in visual inspection and AI analysis to establish a tailored quality control mechanism. This involves real-time detection and adjustment of “Key Process Input/Output Variables” (KPIV/KPOV) to prevent failure modes from affecting subsequent processes.

However, given that the SI specializes in visual inspection software development rather than the installation and maintenance of computers and peripheral equipment, they sought a supplier capable of providing a one-stop solution that includes industrial computers, expansion cards, and GPU cards. This supplier must offer comprehensive after-sales service to address multi-source supply challenges, such as incompatibility and troubleshooting issues. After a thorough evaluation, the SI decided to adopt ADLINK Technology’s complete solution, which includes an industrial PC, image capture card, and GPU card.

Establishing a Digital Inspection Infrastructure with IPC and Image Capture Cards

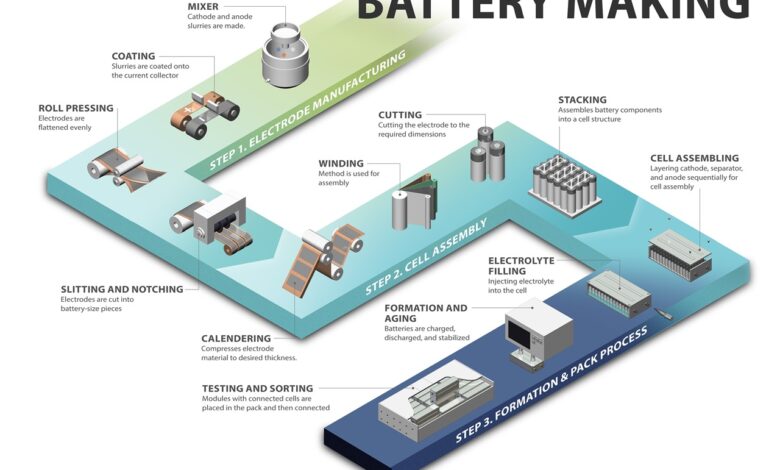

Hsin-Chen Lin, Product Manager at ADLINK Technology’s Edge Computing Platform Product Center, put an emphasis on the battery manufacturing process, which is divided into three stages: initial, middle, and final. The initial stage involves the “electrode production” process, which includes steps such as raw material mixing, coating, electrode pressing, and die-cutting.

The middle stage is the “battery cell assembly,” which involves placing the battery case through winding or stacking methods, followed by sealing through hot pressing, ultrasonic welding, and laser welding. The final stage is “activation testing,” where the battery is activated by injecting electrolytes, followed by charge and discharge testing, and capacity grading and sorting marking the final step.

Electric Vehicle Battery Manufacturing Process

He elaborated further that after the three stages, the battery proceeds to the modularization phase, which includes component gluing, side plate welding, harness installation, and final testing. These steps are pivotal for assembling the final automotive battery module.

Using ADLINK Technology’s IPC and professional image capture card visual inspection solutions for digital inspection enables real-time monitoring during these production stages. This ensures adherence to rigorous manufacturing standards at every step.

Given the complexity of the over ten detailed processes across these stages, numerous critical monitoring and inspection requirements are presented. For example, in the early stage’s coating process, AI technology with Camera Link cards and line scan cameras must accurately detect coating defects and width discrepancies, preventing conductivity issues and material exposure. It ensures the battery’s optimal charge and discharge performance.

Similarly, in the die-cutting process, it is essential to check the electrode tab-cutting precision. Lastly, the middle stage also presents strict challenges, ensuring precise alignment between winding and stacking and mitigating safety risks of low capacity or lithium plating. During ultrasonic and laser welding processes, it is necessary to meticulously inspect the electrode tab welds for scratches, fractures, and wrinkles. AI technology plays a key role here, effectively detecting defects that traditional vision systems may overlook.

In the modularization stage, component gluing and shell welding processes also rely on advanced imaging technology and AI machine learning to inspect the quality which is crucial for preventing component misalignment and electrolyte leakage, thus avoiding potential battery short circuit issues.

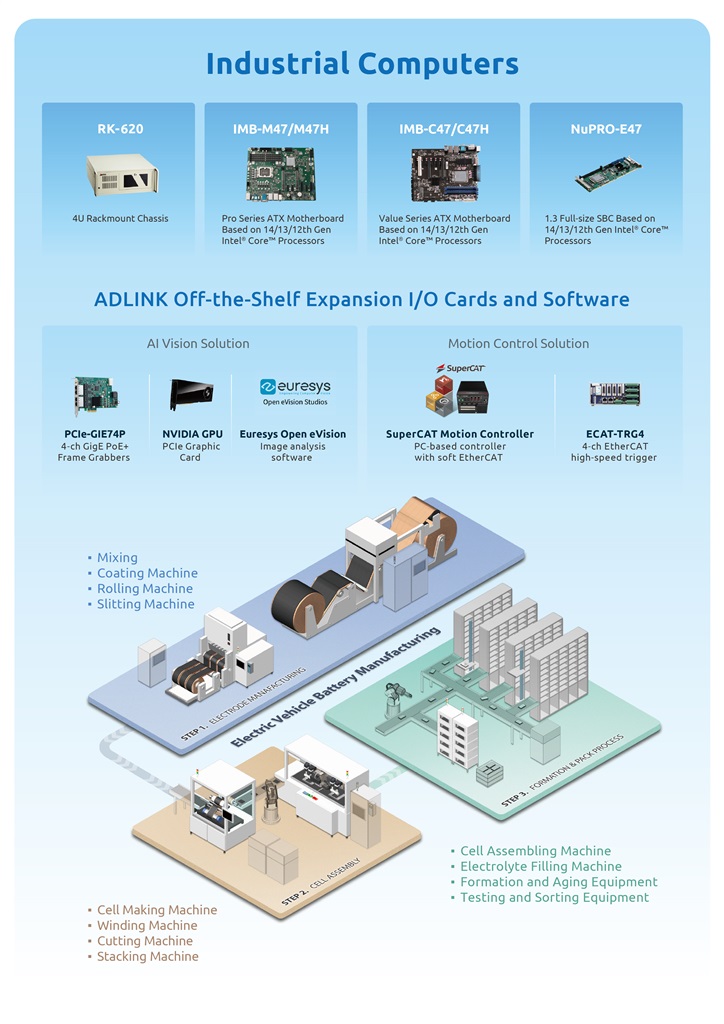

Understanding the specific inspection needs of SIs, ADLINK Technology delivers a complete solution based on the IMB-M47 motherboard as the core of the Industrial Computer (IPC), combined with a dedicated chassis and Power Supply Unit (PSU), paired with the PCIe-GIE74P image capture card and GPU card. This comprehensive solution showcases ADLINK Technology’s thoroughness and expertise compared to most industrial control companies only offering motherboards or Box PCs.

This one-stop solution simplifies system configuration and speeds up the deployment process. It allows SIs to quickly and effectively integrate visual inspection software into battery production equipment, significantly enhancing production efficiency and product quality control.

Leading Electric Vehicle Battery Manufacturing into a New Era of Innovation

ADLINK Technology provides comprehensive support services, allowing SIs to confidently resolve any issues with industrial computers, expansion cards, and other critical components. This enables SIs to focus on software development without worrying about hardware-related problems, thereby helping automotive battery manufacturers reduce inspection time, lower scrap rates, and detect subtle defects. This results in lower production costs while enhancing battery production efficiency and quality.

ADLINK solutions offering for EV battery manufacturing

Hsin-Chen Lin emphasized ADLINK Technology’s latest solution, the IMB-M47 motherboard, highlighting its two significant technological advancements. He noted its superiority, achieved through the utilization of 12th/13th generation Intel Core processors combined with the latest memory and I/O expansion interfaces like DDR5 and PCIe Gen5, offering significantly better processing performance than the commonly used 8th/9th generation processors.

It is complemented by the IMB-M47 motherboard’s ability to support at least two PCIe-GIE74P image capture cards to handle multiple complex inspection tasks. With the increasing demand for visual inspection and the large data volume generated by high-resolution line scan images, the high-performance IMB-M47 motherboard paired with PCIe-GIE74P image capture cards ensures precise and fast inspections, making it an ideal combination.

Comprehensive Expansion Card Solutions Accelerate Intelligent Battery Manufacturing

ADLINK Technology’s greatest advantage in the realm of “intelligent manufacturing for new energy EV battery equipment” stems from its roots in expansion cards. Whether it’s image capture cards, motion control cards, DIO cards, or GPU cards, ADLINK Technology boasts the most comprehensive and high-quality product lineup.

Currently, the primary application involves integrating IPCs and image capture cards for visual inspection. However, across the entire automotive battery manufacturing process, spanning from early to late stages and including equipment such as mixers, coaters, cold press machines, die-cutters, winding/staking machines, and more, ADLINK Technology’s innovative solutions play a vital role.

Through ongoing R&D investments, ADLINK Technology consistently incorporates the latest technology standards and chipsets into its industrial computer systems, significantly boosting processing speed, data transfer efficiency, and reliability. Furthermore, ADLINK Technology’s internal expansion card solutions effectively tackle compatibility issues faced by system integrators, further enhancing overall production efficiency.

These innovative technological solutions reinforce ADLINK Technology’s leadership in the automotive battery manufacturing sector and establish it as the preferred partner for automotive battery manufacturers, production equipment suppliers, and system integrators.

Learn more about ADLINK Industrial PC or contact ADLINK for more information about products and solutions.