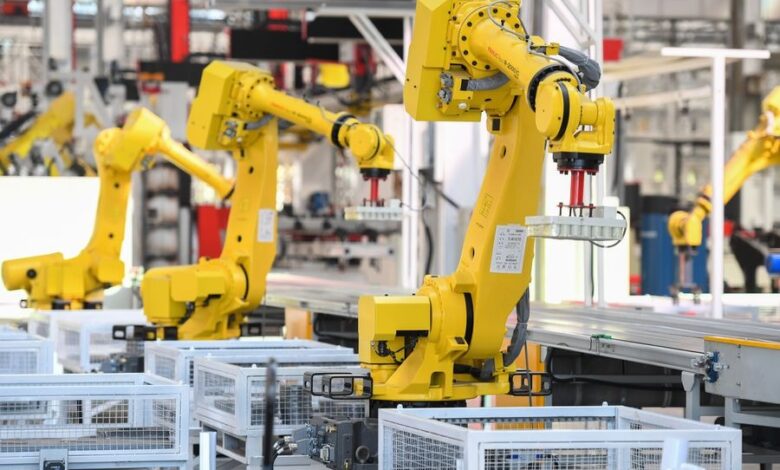

Ascending local brands make their mark on rising robots

BEIJING — The dawn of the industrial robot era began in 1959 with the debut of the hydraulically powered Unimate, marking a significant leap in automation technology.

Over the subsequent decades, the market was dominated by the “Big Four” including Japan”s FANUC and Yaskawa. These titans have leveraged their extensive technological heritage and industrial production experience to maintain a market share consistently above 50 percent.

However, the landscape is shifting as Chinese players break through the ranks.

With the world’s largest manufacturing sector at its disposal, China has emerged as the largest consumer market for industrial robots globally. In 2013, it overtook Japan to claim the top spot and has maintained this position for 11 consecutive years.

Data from the research institute GGII indicates that domestic Chinese brands have seen a sustained and rapid increase in sales of industrial robots, surpassing foreign brands with over 160,000 units sold in 2023. This is the first time the home-made share has exceeded 50 percent.

The growth in market share is paralleled by the rise of domestic excellence, as innovative homegrown enterprises are having more market presence in producing the core components of robots, once a field dominated by foreign brands.

An example is Shanghai STEP Electric Corporation, which has spearheaded collaborative research and development among 12 upstream and downstream enterprises along the Yangtze River Delta. This initiative has led to the application of domestically produced robot parts in complete machine units.

The firm’s president Liang Rui stated that the regional industrial chain and the continuous advancement in core technological capabilities have accelerated the adoption of domestic robots in factory settings.

For instance, the arc welding robots used in automobile production lines now boast controllers from Shanghai, servo motors from Zhejiang, reducers from Jiangsu, and casings from Anhui, with the three major core components locally manufactured thanks to the system integration from within the Yangtze River Delta region.

From a collaborative perspective, the synergy in robot-making epitomizes China’s strategy to capitalize on its strengths by integrating the capabilities of regional industrial and innovation chains.

The Yangtze River Delta region is a powerhouse of economic and innovative activity in China. With its advanced manufacturing, a dense network of thriving industries, and a strong entrepreneurial spirit, the region is a hub for technological innovation and sustainable development.

Shanghai is the first city in China to count robot density — the number of robots per 10,000 employees. At present, the robot density of key industrial enterprises in Shanghai has reached 426 units, leading the international field.

According to an action plan issued by the central government in 2023, by 2025, China’s robot density in manufacturing sector will double from that of 2020. While in Shanghai, the robot density in key industries will reach 500 units in 2025.

A market report revealed that there was not much of a performance difference between the robots manufactured along the Yangtze River Delta and comparable models manufactured by global leading brands in terms of dozens of evaluation sub-items.

The introduction of industrial robots has led to a quantum leap in production efficiency and cost savings. Take the new energy vehicle industry as an example, industrial robots have given rise to a batch of “unmanned factories,” capable of rolling out a vehicle within a few tens of seconds.

From 2015 to 2022, China’s annual production of industrial robots soared from 33,000 units to 443,000 units. The latest data from the National Bureau of Statistics shows that the production volume in the first quarter of this year reached 120,000 units.

After rapid development in recent years, China’s industrial robot industry has made significant strides in both product technology and practical application, setting the stage for companies to expand into larger markets overseas.

According to the International Federation of Robotics (IFR), in 2023, China’s export volume of industrial robots reached a new high of 118,300 units, while the import volume was 82,400 units.

Han’s Robot Group’s General Manager Wang Guangneng noted that Chinese robot brands are primarily sold to developed markets such as North America, Japan, Germany, and South Korea, as well as rapidly industrializing markets like Latin America and Southeast Asia.

“Companies are keen to use robots to achieve automation to lower cost,” said Wang. “Our six-axis collaborative robots have a work efficiency comparable to that of an average worker, but they can work around the clock, effectively equivalent to the workload of two workers,” he added.

Wang also mentioned that their products allow most customers to recoup their investment within a few months.

As Made-in-China robots, ranging from mobile to collaborative models and extending into cutting-edge applications, expand their global reach, they emerge as a pivotal catalyst for the advancement of the worldwide manufacturing sector.