Bamboo Cloud / llLab. | ArchDaily

Text description provided by the architects. Bamboo Cloud’s original idea was to create a spontaneous place that sparks encounters and gatherings.

In January 2022, because one of our built projects Bamboo Bamboo Canopy and Pavilions in Yangshuo, Guilin was seen on the Internet by the organizer of NYC x Design from New York City, we were invited to design a bamboo made project specifically for the public area at Gansevoort Plaza in New York. This gave us an opportunity to start researching on how to create/construct bamboo weaving and movable natural environments using methods that can be assembled and disassembled.

After the completion of the original Bamboo Bamboo Canopy and Pavilions, in Yangshuo, we have received some invitations from other countries to participate in weaving construction or exhibitions, but due to time constraints, geographical location and transportation restrictions, it was not possible. However, this opportunity, the delayed schedule caused by the pandemic, gave us time to re-imagine, and also contributed to this breakthrough process about the use of materials and production.

The theme of the exhibition is Open To The Sky. Then how to maximize the effect from the woven bamboo while simultaneously making the structure disappear and making the floating bamboo clouds the lightest form of expression has become a crucial goal. The choice of bamboo, a natural material, and the hand-woven method used by Bamboo Cloud, although they can stimulate awareness of nature and perception of the environment, will be limited by the geographical factors of handwork and the source of the material.

Bamboo Cloud’s overall creative and construction concept attempts to break this innate limitation by using an assembly method that allows it to break through geographical and material boundaries, thereby bringing natural consciousness and natural space to more previously unreachable areas, such as here, like a clump of fibers floating over New York City.

This seemingly contradictory physical expression prompted us to overturn previous experience and rethink the entire structural system, weaving, form-finding, construction and installation, and all other key construction procedures. Bamboo is still relatively ambiguously defined, though bamboo has been applied in various aspects in the field of architecture. In terms of structural calculation and material properties, it can still only be compared with wood in the role of “engineered bamboo”, for imperfect construction implementation.

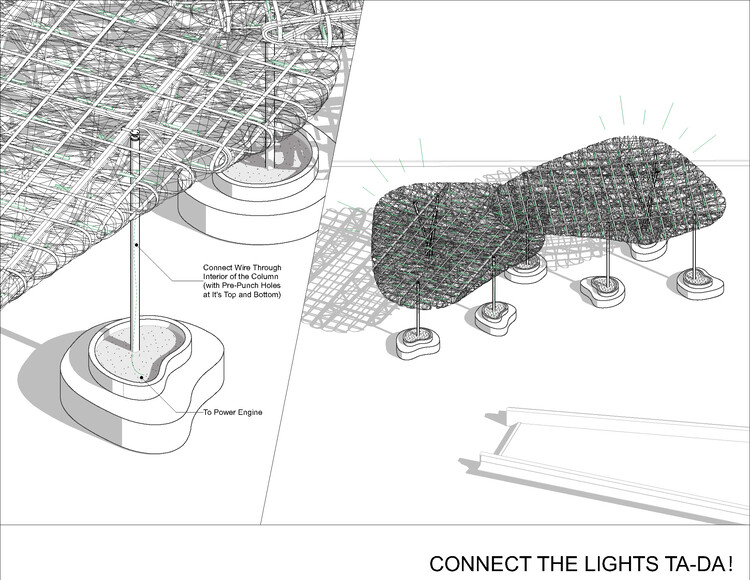

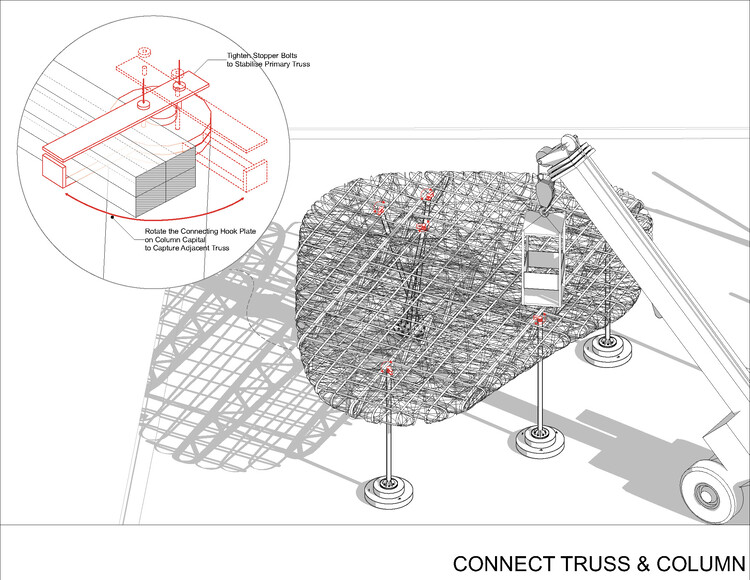

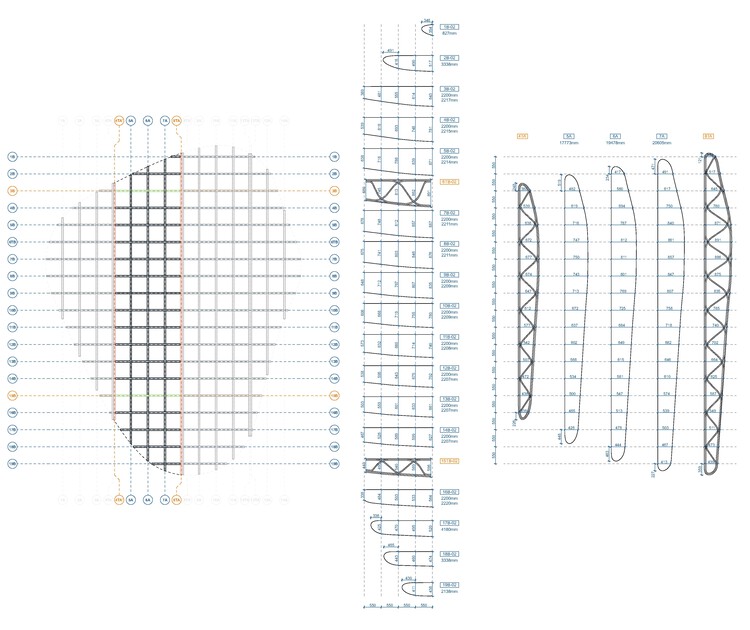

However, the Bamboo Cloud intends to unify original bamboo and engineered bamboo in terms of materials and applications, as well as their properties and physical presentation. Bamboo has its own resilience and its materialistic stress, but assembly process cuts off the force transmitted by the material itself to a certain extent. Therefore, considering transportation and overall composition, an accurate segmentation direction is determined, thus defining the bamboo cloud itself. The assembly logic is that the critical line of segmentation becomes the positioning axis of the bamboo truss of the main structure (also defined as the holding point of the vertical supporting structure), and the structural support and form-finding of the remaining woven layers are all based on the auxiliary trusses. And the rest is defined by the mutual constraints of the bamboo strips themselves.

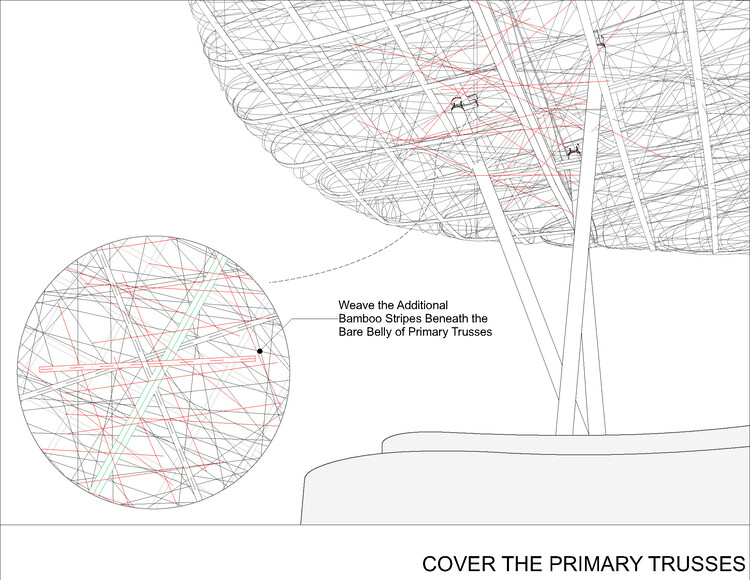

The format of the main truss is limited by the inner dimensions of the shipping container to achieve the maximum coverage. The traditional use of rods and nodes of the truss structure and the triangular sub-frame, with our concept of using bamboo, becomes very inconsistent and contradictory in terms of the material physical property. Therefore, the production of bamboo truss structure also overturned the traditional logic of truss nodes and rods, and combined the two into one to form a wave form, with multiple arcs bending and joining each other. The interlocking joint between the “waves” also allows the material properties of bamboo to be continuous in the structural plane and within its own direction. The all contacting points have been extended to surficial contact, that can help evenly distribute the pressure to avoid stress concentration.

At the same time, in order to maximize the effect of “disappearing structure”, the weaving process is carried out without relying on the structure at all, and bamboo strips are used to hold each other as the main structure of the weaving part of the bamboo clouds to support and fix. 12 main trusses, 16 auxiliary trusses, and about 10,000 bamboo strips form a bamboo cloud space of about 120 square meters, hoping to bring a completely new exploration to the Gansevoort Plaza in the New York City. Bamboo Cloud focuses on the relationships between inherent material properties and their potential applications beyond convention. Bamboo has been mainly applied on the scale of handcraft, followed by the recent popularization of its utilization in sustainable buildings. However, the advantage of utilizing bamboo has not been thoroughly understood, so most applications have remained superficial.

The idea of making Bamboo Cloud has further triggered the integration of form and structure. The process investigated performance extremes in order to optimize efficiency by using bamboo as the most organic construction material beyond its commonly applied fields. During prototyping, bamboo strips less than 5 mm thick and less than 5 cm wide are used to test the threshold for lightweight construction. The process places particular emphasis on the unique material properties of bamboo, which could potentially inspire a wider range of construction applications. Bamboo Cloud, a porous volume made of woven bamboo stripes, naturally finds its form due to the internal resilient force in the material and eventually stabilizes as a volumetric object, making it a potential implementation at building scale. Bamboo Cloud visualizes its inherent force in the form itself, which therefore makes it possible to grow architecturally and culturally.