Chinese carmaker Dongfeng to use humanoid robots in factory

Chinese car manufacturer Dongfeng Motors is set to use humanoid robots to help make cars.

When people say that robots are coming for our jobs, they’re not always joking.

We’re seeing the effects of automation all over the world, and China is no exception.

Where are the humanoid robots going to be working?

Chinese state-owned Dongfeng Motor is partnering up with robotic firm UBTech to automate its manufacturing process.

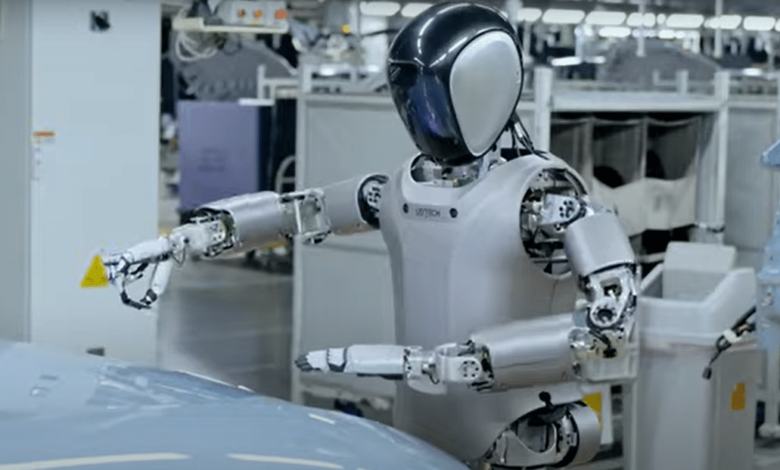

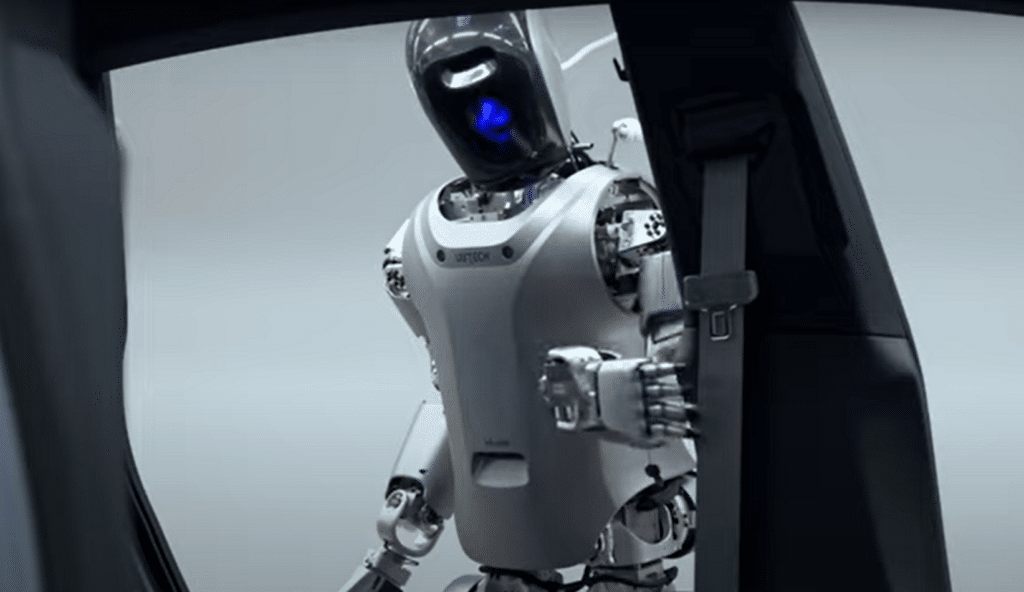

The Walker S humanoid robot will be carrying out different tasks on Dongfeng Motor’s production lines.

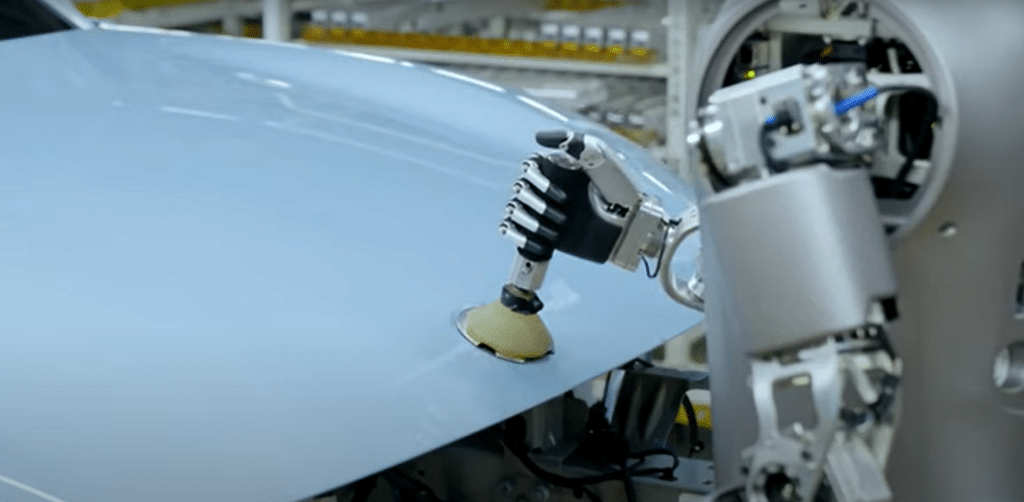

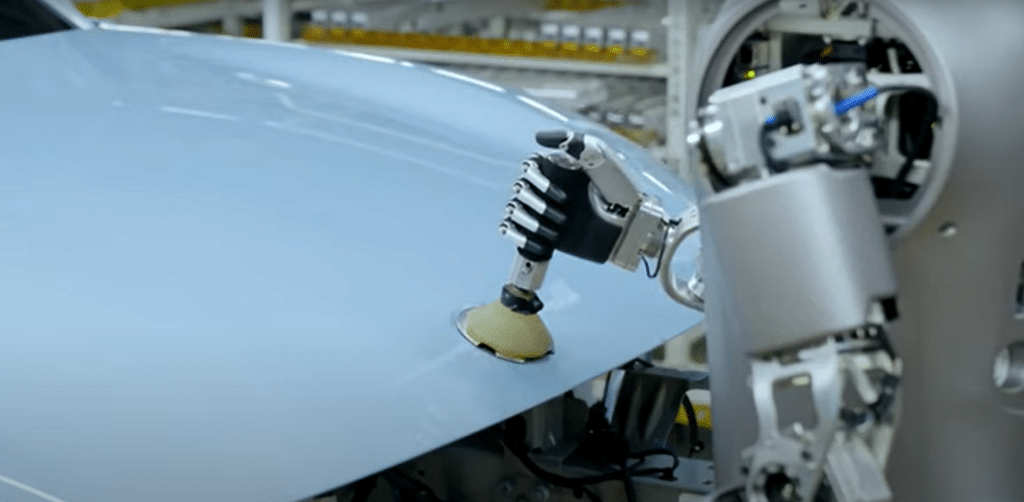

This will include safety belt inspections, door lock testing, body quality testing, oil filling, and label application.

The robot will be integrated with traditional machinery to handle more complex scenarios.

Walker S, a robot that is 1.7m (5 foot 5 inches) tall, communicates with the factory’s system and shares collected data in real time.

Through hands-on training, the robots are expected to enhance their capabilities in assembling components.

Currently, automaker Nio already uses them in their manufacturing plants.

Lin Changbo, the General Manager at Dongfeng Motor, said of the development: “This will not only bring greater improvement to Dongfeng Motor’s intelligent manufacturing level, but will also become a new style of intelligent manufacturing in the automotive industry.

“[It] will accelerate the scene-based and large-scale application of humanoid robots in the automotive industry.”

Why is Dongfeng choosing to use robots?

The humanoid robot has many qualities which make it a valuable asset on the factory floor.

It has vision cameras and depth sensors that allow it to navigate the environment, whilst its capacity to recognize 3D objects allows for obstacle avoidance.

Human-like hands allow them to take on jobs involving the manipulation of materials.

Walker S can carry 3 kilograms in each hand.

China is reported to have 12 times more robots within its workforce than experts predicted, making it the largest robotics market in the world.

It’s estimated that automation could boost global productivity growth by 0.8 to 1.4 percent annually.