How Virtual Incision designed the mini, mighty MIRA surgical robot

The Virtual Incision MIRA Surgical System’s design was small to start with — and then came an opportunity to test aboard the International Space Station.

Virtual Incision’s MIRA (Miniaturized In Vivo Robotic Assistant) Surgical System [Photo courtesy of Virtual Incision]

In conversations with Medical Design & Outsourcing, surgical robotics developers often say they try to use as many off-the-shelf components as possible.

That wasn’t possible for the MIRA (Miniaturized In Vivo Robotic Assistant) Surgical System, Virtual Incision co-founder and Chief Technology Officer Shane Farritor said.

“Everything in our device is quite custom … from scratch, bespoke,” he said in an interview. “… Our robot’s different than everyone else, because it’s miniature, and we think miniature is big.”

Virtual Incision’s MIRA won FDA de novo classification in February 2024 as a table-mounted miniaturized electromechanical surgical system. Around the same time, Virtual Incision sent a modified version of the system called spaceMIRA to the International Space Station to test how well surgeons on Earth could control the robot in orbit.

“The story starts with the University of Nebraska Medical Center,” Farritor said. “I was on faculty at the engineering college, but the medical center acquired the eighth da Vinci ever sold. They were very early adopters of robotic surgery and they hired my co-founder, Dr. Dmitry Oleynikov, to start a robotic surgery program. And this is 2002, 2003 — really, really early. He and I both thought that there’d be another way to do surgery, that it should be small robots that go inside the body rather than big robots reaching in from the outside. Da Vinci is an incredible machine, maybe the best medical device ever made. But we think there’s also an advantage to small devices. So we started making little robots.”

In the beginning, those robots looked like miniature versions of the rovers NASA sent to Mars. Before joining the University of Nebraska, Farritor worked on the Mars Rover project through Massachusetts Institute of Technology’s Field and Space Robotics Laboratory and the C.S. Draper Laboratories Unmanned Vehicle Lab.

Virtual Incision’s research won funding from the U.S. government “because NASA and the Army want to do surgery in crazy places, and miniature devices lend themselves to crazy places,” Farritor said.

Virtual Incision is designing more devices for soft-tissue, abdominal procedures.

“We think every surgical procedure can be addressed with a miniature robot,” Farritor said.

DeviceTalks Boston: Meet Virtual Incision’s MIRA robot at our medtech show May 1-2, 2024

Designing a miniature surgical robot

The Virtual Incision MIRA Surgical System’s arm weighs around 2 lbs. [Photo courtesy of Virtual Incision]

“Most of the other devices are big robots on the outside,” Farritor said. “That means you put big motors on the outside, and then you have usually cable transmission into the body to actuate the tips of the instruments. That has a lot of advantages, but you have a bigger motor and then you have to have a bigger motor to hold that motor and it snowballs into a big device.”

So Virtual incision designed MIRA with local actuators, placing miniaturized motors closer to where the robot’s instruments would actually be working.

Related: Maxon helped get Virtual Incision’s surgical robotics system to space

“Mechanically, our robots are pretty tightly packed and that can cause all kinds of other problems, but we think it has all sorts of advantages to the challenges we think we’ve overcome,” he said. “You can’t have big motors, you have to use little motors efficiently. Efficiency is a big issue, heat dissipation, all these sorts of things start to come into play. But we think MIRA is a fantastic device and shows the feasibility of this approach.”

One advantage is the ability to quickly move from quadrant to quadrant within a patient.

“To go from the rectum all the way up to the spleen, over to the liver, and then down to your cecum happens in seconds with our device,” he said. “There’s no docking, there’s no undocking, there’s no instrument change required. Multiquadrant access is one of the powerful aspects of miniature.”

MIRA’s rigid arms with motors mounted inside provide strength while fully enabling triangulation of the camera and instruments.

[Photo courtesy of Virtual Incision]

Another advantage of miniaturization is constant triangulation. Instead of a multiport system that inserts instruments from several incisions and comes together inside the patient, the MIRA system is internally triangulated when it drops in.

“It’s really inherent with the design of the device and it’s again part of being miniature. The surgeon always gets the same first-person view, like we’ve shrunk them down and put them inside the body,” he said.

For simplicity and ease of use, Virtual Incision designed the MIRA system with a single cable and to use only four disposables — and no drapes. The system can be set up in six to eight minutes.

“Our focus has always been on simplicity in the operating room, and that’s been the driving ethos in the work that we do. We want to make our system easy to use so that you don’t need special teams to be trained and you can do surgery in forward environments, you can do surgery at night. All these things that make it simpler, we think also makes it more useful. One of the effects of simplicity can be low cost.”

MIRA is also designed for up to 15 cycles of reuse with vaporized hydrogen peroxide (VHP) sterilization. Ethylene oxide is difficult to work with and the surgical robot can’t be sterilized with an autoclave, so VHP is “the next-simplest” method of sterilization, Farritor said.

“It made sense for us,” he said. “It’s another step toward simplicity and sustainability.”

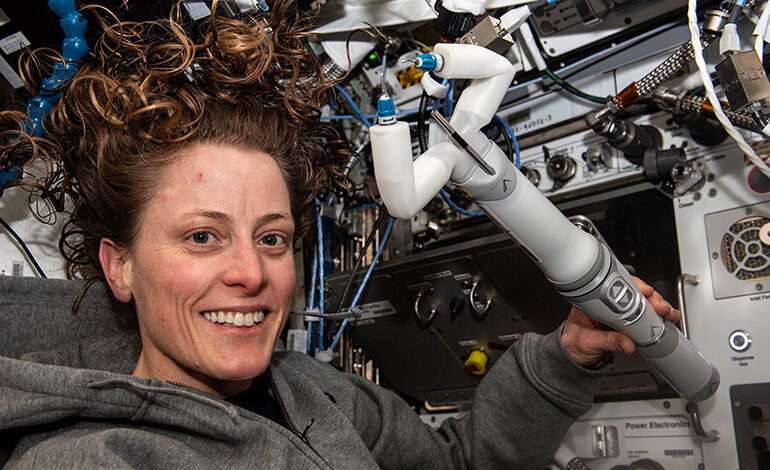

Making MIRA even smaller for space

NASA astronaut and Expedition 70 Flight Engineer Loral O’Hara poses with Virtual Incision’s spaceMIRA aboard the International Space Station. [Photo courtesy of NASA]

Virtual Incision modified MIRA into an even more compact spaceMIRA to fit inside a NASA-provided locker aboard the International Space Station. Those microwave-size lockers fit in EXPRESS Racks, short for “expedite the processing of experiments to space station.” Those racks have connections for power, data and video, plus cooling, water, nitrogen supply and vacuum exhaust.

To fit into one of those lockers, SpaceMIRA is about three inches shorter than its Earth-bound predecessor.

“MIRA has a long straight section that will accommodate different abdominal wall thicknesses and different surgical targets inside the body so you can extend to different targets. We didn’t need to do all that in our experiment, so we were able to shorten it and fit it in the diagonal of that EXPRESS Rack locker. That really simplified the operation,” Farritor said. “NASA does a lot of these lockers and they know how to handle them, so that really simplified our in-flight operations.”

Virtual Incision conducted two experiments aboard the ISS. The first was a pre-programmed run for semi-autonomous surgery, testing how well the surgical robot could cut rubber bands on its own as a simulation of surgical tasks.

Shane Farritor controls spaceMIRA while his Virtual Incision co-founder Dr. Dmitry Oleynikov watches. [Photo courtesy of Virtual Incision]

The second experiment was to test and demonstrate telesurgery, giving surgeons on the ground control of the robot as it orbited 250 miles above Earth. They performed simple and advanced tasks despite 600-800 ms of latency.

“They learn to deal with the delay. This was only simulated surgery, but I was really encouraged that they were all able to do the task,” Farritor said. “It’s preliminary, but they all moved very deliberately, so the total distance traveled was actually less than when they would do these procedures on Earth. … It really just confirms and encourages a lot of the things that we’re already doing.”

The Virtual Incision team will review data from spaceMIRA after it returns to Earth to learn more.

Advice for device designers and engineers

Virtual Incision has what Farritor described as a “building ethos.”

“We make things and try them quickly, over and over and over again,” he said. “It’s very easy in the medical device industry to forget that and to try to get everything perfect before you try something. You have to look for ways to make little bets, to try small versions or test different aspects of what you’re trying to do in a physical way. and as clinically relevant as you can. So we really encourage that quick iteration and quick design process.”

“The saying is measure twice and cut once,” he continued. “Don’t measure. Just start cutting. Boards are cheap. If you’re measuring twice, you’re probably following a plan and following a plan means you’re probably not being as innovative as you could. So don’t measure — cut twice.”