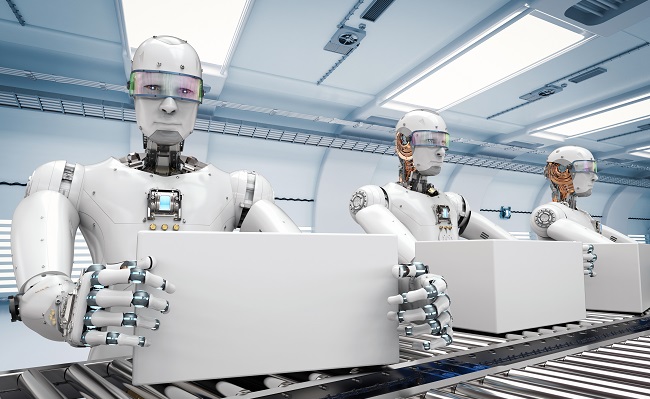

Humanoid robots tipped for industrial impact

Management consultancy Horvath predicted deployment of robots with a more human-like form than those commonly used in factories would be bolstered by technological advancements and a drop in price resulting from mass production in the coming years.

In the company’s Humanoid Robots in Operations report it pinned 2025 as the date when mass production of the machines could begin, with that development expected to cut the price of the units from an average €80,000 to €48,000 by 2030.

It noted current acquisition costs for humanoid robots were higher than other industrial robots.

Horvath added these human-form machines would also require maintenance costs of around €4,000 per year.

Alongside a benefit from an anticipated cut in price, by 2030 the company expects continued increases in sophistication, with the units likely to surpass human capabilities in terms of “speed of movement, flexibility and fine motor skills”.

Currently, Horvath noted, common industrial robots used for the likes of welding, assembly and quality inspection resembled human arms. Humanoid robots, on the other hand, are as tall and heavy as actual people making them “them particularly suitable for working in environments designed for humans”.

The consultancy’s senior project manager Tobias Bock said there were many potential applications for the human scale robots, adding they could “take on particularly labour-intensive, physically demanding and repetitive tasks in production and logistics.”

It anticipates robots could take over more than half of manual tasks currently in the production line.

Among early pilot projects being undertaken in this area is a deal announced earlier this year between Mercedes-Benz and Apptronik to use the latter’s Apollo robot, with the automotive giant assessing use cases including delivering parts to human workers while simultaneously inspecting the components.