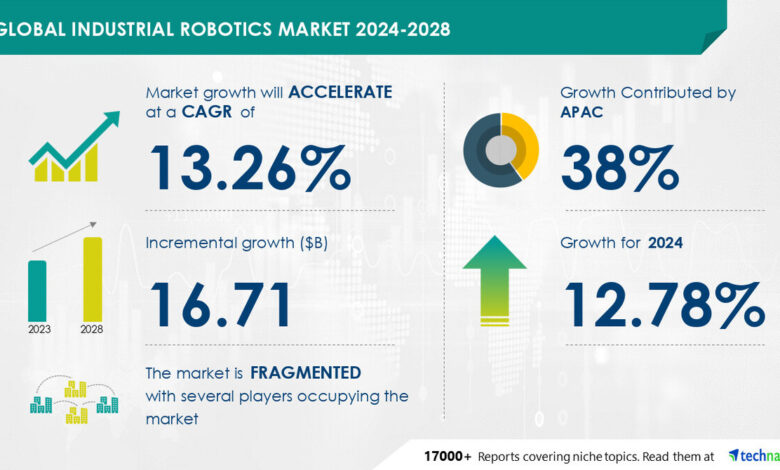

Industrial Robotics Market size is set to grow by USD 16.71 billion from 2024-2028, Surge in demand for industrial robots to boost the market growth, Technavio

NEW YORK, May 23, 2024 /PRNewswire/ — The global industrial robotics market size is estimated to grow by USD 16.71 billion from 2024-2028, according to Technavio. The market is estimated to grow at a CAGR of 13.26% during the forecast period.

For more insights on the forecast market size and historic data (2018 – 2022) – Download Free sample report in minutes

|

Forecast period |

2024-2028 |

|

Base Year |

2023 |

|

Historic Data |

2018 – 2022 |

|

Segment Covered |

Type (Articulated, SCARA, Cylindrical, and Others), End-user (Electrical and electronics, Automotive, Metal and machinery, Pharmaceuticals, and Others), and Geography (APAC, Europe, North America, South America, and Middle East and Africa) |

|

Region Covered |

APAC, Europe, North America, South America, and Middle East and Africa |

|

Key companies profiled |

ABB Ltd., b m surface systems GmbH, Comau Spa, DENSO Corp., Durr AG, FANUC Corp., Kawasaki Heavy Industries Ltd., MIDEA Group Co. Ltd., Mitsubishi Electric Corp., NACHI FUJIKOSHI Corp., OMRON Corp., Relay Robotics Inc., Rethink Robotics GmbH, Robert Bosch GmbH, Rockwell Automation Inc., Seiko Epson Corp., Shenyang Xinsong Robot Automation Co. Ltd., Staubli International AG, Teradyne Inc., and Yaskawa Electric Corp. |

Key Market Trends Fueling Growth

In Singapore and beyond, the Industrial Robotics Market is experiencing significant growth, driven by quality and delivery demands in various sectors. IoT capabilities are becoming essential, influencing robot applications and operation modes. Articulated robots, such as those from Yaskawa Electric and Denso, are trending, offering real-time performance data and automating tasks in material handling, assembly, and welding. Competition in the U.S., France, India, and other regions intensifies, pushing for advancements in robot safety, efficiency, and productivity.

Market Challenges

- The industrial robots market experiences growth due to benefits such as precision, flexibility, and consistency in manufacturing processes. However, the shortage of skilled workers with the necessary qualifications to collaborate with these advanced technologies poses a significant challenge. Robotic solutions, including cobots and machines with multiple axes, are integral to Industry 4.0 and the forefront of automation.

- Yet, the need for trained engineers and operators to handle roles like soldering, painting, and integration with sensors and supply chains remains a capacity concern. In regions like Africa, the Middle East, Brazil, South Africa, and emerging economies like China and India, labor costs and the need for skilled labor further complicate the market landscape.

- Despite these challenges, the adoption of robotics technology, artificial intelligence, and automation solutions continues to scale, shaping the future of manufacturing industries.

Research report provides comprehensive data on impact of trend, driver and challenges – Download Free sample report in minutes

Segment Overview

- Type

- 1.1 Articulated

- 1.2 SCARA

- 1.3 Cylindrical

- 1.4 Others

- End-user

- 2.1 Electrical and electronics

- 2.2 Automotive

- 2.3 Metal and machinery

- 2.4 Pharmaceuticals

- 2.5 Others

- Geography

- 3.1 APAC

- 3.2 Europe

- 3.3 North America

- 3.4 South America

- 3.5 Middle East and Africa

1.1 Articulated- The industrial robotics market is segmented by type, with articulated robots occupying a prominent role due to their handling capabilities and versatility across industries such as automotive, metals and machinery, and pharmaceuticals. These robots, renowned for their precision and dexterity, offer a variety of applications, including soldering, painting, and assembly lines.

The global shortage of skilled labor and the need for increased product quality have fueled the deployment of articulated robots in manufacturing processes. With Industry 4.0 at the forefront, these robots are integrated with sensors and artificial intelligence to enhance capacity and consistency on production lines. The market for articulated robots is forecasted to grow significantly in Africa, the Middle East, Brazil, and other emerging markets.

The majority of industries are turning to robotics technology to address labor costs, maintenance, and flexibility needs. The most common configuration for articulated robots is the 6-axis robot, which offers six degrees of freedom and the ability to reach any point within its workspace. Additionally, the emergence of cobots and advancements in robotics technology are expected to further scale the market.

For more information on market segmentation with geographical analysis including forecast (2024-2028) and historic data (2018 – 2022) – Download a Sample Report

Research Analysis

The Industrial Robotics Market is experiencing significant growth due to the automation of tasks in various sectors, including manufacturing processes for vehicles, material handling, and welding. Technologies such as SCARA robots, cobots, and industrial vehicles are driving productivity and flexibility in development, enabling factories to increase capacity and improve product quality.

The integration of sensors, artificial intelligence, and forecasting tools enhances consistency and reduces labor costs, while also improving maintenance and integration with assembly lines and supply chains. The role of industrial robots extends to sectors like painting and soldering, providing precision and reducing the need for human intervention.

Industry 4.0 is pushing the forefront of robot market development, with machines becoming smarter and more cost-effective, leading to a transformation in production lines and the overall industry landscape.

Market Research Overview

The Industrial Robotics Market encompasses a wide range of automated systems designed for various industries to enhance productivity and efficiency. These robots are integral to modern manufacturing processes, providing solutions for tasks such as welding, painting, assembly, pick and place, and material handling. The market is driven by factors including the increasing demand for automation in industries, the need for cost savings, and the continuous advancements in robotics technology.

Furthermore, sectors like automotive, electronics, and food and beverage are significant contributors to the market’s growth. The future of industrial robotics lies in the integration of advanced technologies like AI, machine learning, and IoT, enabling more sophisticated applications and improving overall performance.

Table of Contents:

1 Executive Summary

2 Market Landscape

3 Market Sizing

4 Historic Market Size

5 Five Forces Analysis

6 Market Segmentation

- Type

- Articulated

- SCARA

- Cylindrical

- Others

- End-user

- Electrical And Electronics

- Automotive

- Metal And Machinery

- Pharmaceuticals

- Others

- Geography

- APAC

- Europe

- North America

- South America

- Middle East And Africa

7 Customer Landscape

8 Geographic Landscape

9 Drivers, Challenges, and Trends

10 Company Landscape

11 Company Analysis

12 Appendix

About Technavio

Technavio is a leading global technology research and advisory company. Their research and analysis focuses on emerging market trends and provides actionable insights to help businesses identify market opportunities and develop effective strategies to optimize their market positions.

With over 500 specialized analysts, Technavio’s report library consists of more than 17,000 reports and counting, covering 800 technologies, spanning across 50 countries. Their client base consists of enterprises of all sizes, including more than 100 Fortune 500 companies. This growing client base relies on Technavio’s comprehensive coverage, extensive research, and actionable market insights to identify opportunities in existing and potential markets and assess their competitive positions within changing market scenarios.

Contacts

Technavio Research

Jesse Maida

Media & Marketing Executive

US: +1 844 364 1100

UK: +44 203 893 3200

Email: [email protected]

Website: www.technavio.com/

SOURCE Technavio