Innovations in Electric Vehicle Batteries, with Micah Ziegler

The Full Transcript

Kristin Hayes: Hello, and welcome to Resources Radio, a weekly podcast from Resources for the Future. I’m your host, Kristin Hayes. Today’s episode is the second in our series on electric vehicles (EVs). As I was thinking about guests and topics, I knew early on that I wanted to speak to someone about the future of battery technology. I would argue that how batteries evolve, particularly in terms of range and cost, may make or break the adoption of EVs. So, what might car buyers see in the next decades?

Today, I’ll be talking about batteries with Dr. Micah S. Ziegler, an assistant professor at Georgia Tech in the School of Chemical and Biomolecular Engineering and the School of Public Policy. Micah earned his PhD and bachelor’s degrees in chemistry, and he now evaluates sustainable energy and chemical technologies, their impact, and their potential. His postdoctoral research at the Massachusetts Institute of Technology (MIT) was particularly focused on energy storage. Today, Micah and I are going to take a deep dive on batteries, and he’ll also provide some insights from his own research on how best to spur innovation in this space moving forward.

Two quick notes about our series. If you missed a previous episode, feel free to click around in the show notes or the podcast homepage to catch up. If you decide you don’t need to know all the details about EVs, no worries. Just tune in again after a few weeks when we’ll return to our normally scheduled programming, but of course, I hope you’ll stay with us.

Hi, Micah. It’s a pleasure to talk with you today, and I’m really glad that you’re here on Resources Radio to talk about electric vehicle battery technology.

Micah Ziegler: Thank you for having me. I’m delighted to be here.

Kristin Hayes: Great. Before we get to that topic, I’d love to know more about your background, of course, and in particular, how you came to work on clean energy technologies as a chemist.

Micah Ziegler: I’ve been interested in addressing environmental issues since my childhood. I was especially inspired by visits to national parks. As an undergrad at Yale, I considered many different ways I could have an impact. I considered working in advocacy or going to law school, and over time, I found that I wanted to leverage my interest in strengths in science and research broadly and apply those to addressing environmental challenges. After a few years working on climate and energy policy at the World Resources Institute in Washington, DC, I decided to pursue a PhD in chemistry.

At the time, I already knew that climate scientists were doing great work to describe climate change and its impacts. I wanted to do something different. I wanted to focus on studying possible solutions to environmental challenges. I chose to study chemistry to better understand and contribute to the science that underlies many of the possible technologies we could use to reduce greenhouse gas emissions to mitigate climate change. My first project in graduate school at the University of California, Berkeley, was actually focused on how to take carbon dioxide out of the air and turn it into anything that was not carbon dioxide.

Toward the final years of my graduate research, I found myself increasingly asking why some technologies succeed while others do not. Many things we can do in the lab never make it to broad deployment. For example, my colleagues could make an artificial leaf that could store energy from sunlight by splitting water, but I couldn’t get one for the roof of my apartment. I wanted to study this gap quantitatively to better understand why some technologies make it onto the roofs of houses while others never leave the pages of a lab notebook; to understand why some technologies improve rapidly while others do not.

I turned to studying energy systems and technological change. I studied these subjects for a few years at MIT, as you mentioned, and I’m continuing to do so here at Georgia Tech.

Kristin Hayes: It’s great to have someone with your breadth of experience join me to talk about EV batteries, and it’s great to have a chemist, in particular. Let’s start with a little bit of historical context on the battery side. My understanding is that in the early days of the automotive industry, battery-powered vehicles were actually developed alongside the typical internal combustion engine vehicle. But essentially, internal combustion engine technology won out. What did those early EV batteries look like, and what’s your sense of why batteries didn’t stay prevalent early on?

Micah Ziegler: You’re entirely correct. Battery-powered vehicles were relatively common in the early 1900s. Some estimates suggest that for a while, there were as many electric cars as there were gasoline-powered cars. These electric vehicles were used in both personal and commercial contexts. For example, the US Postal Service in New York City had a few electric trucks, which reportedly had the capacity to run for 45 miles on a single charge. Many of those early EV batteries were lead acid batteries, which were introduced in the late 1850s, decades earlier.

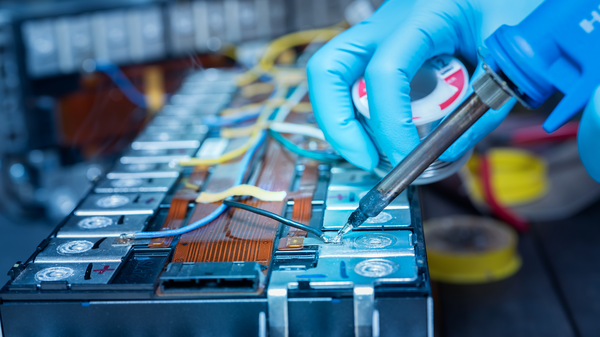

These batteries contained lead and sulfuric acid. They were heavy. They required frequent maintenance. Like today’s EV batteries, many smaller battery cells were combined to form the larger batteries used in vehicles. Also like today, there were competing battery chemistries. Notably, some vehicle manufacturers offered the option to upgrade batteries to those that relied on nickel and iron.

Of course, when one technology outcompetes another, as gas-powered vehicles outcompeted electric options, there are often multiple factors that play a role. One major factor here was that the batteries were quite limited in the amount of energy that could be stored within a given weight, what is known as the specific energy. In turn, this really limited both the range and the speed of these early electric vehicles.

Moreover, while big cities had charging infrastructure, beyond the cities, charging options were scarce. As road infrastructure improved and expanded and gasoline became more available, gas-powered automobiles became more popular. Gas-powered cars allowed people to travel further and faster and could be refilled beyond the cities.

Another factor though was the integration of small batteries into these gasoline-powered vehicles. Previously, gas-powered cars needed to be started with a crank. It was hard work. Batteries allowed gas-powered vehicles to be started more easily and also powered their lights. In essence, batteries brought some of the convenience associated with electric vehicles at the time to gas-powered options. Batteries were still critical but as a component in the gas-powered cars.

Kristin Hayes: Got you. It’s interesting to think about—you mentioned charging infrastructure, and it’s funny, I hadn’t even thought about what charging infrastructure in those early days might possibly have looked like, but it’s an interesting mental image, and I definitely have a mental image of the crank that one would use to start cars.

You also referenced different battery chemistries. Lead and sulfuric acid don’t sound like the most wonderful combination of chemicals, but there certainly are many different combinations of materials. I think today, lithium-ion batteries are the most common battery in use in electric vehicles and in many other applications but certainly in batteries for EVs. How did that particular combination of materials come to dominate?

Micah Ziegler: Researchers have long focused on using lithium in batteries. It is the third-lightest element, and it supports high voltages, which can enable substantial amounts of energy to be stored in lightweight batteries. For many decades, people have made batteries using lithium metal, and they still do. For example, some of the coin-shaped cells that you might replace every couple of years in small portable electronics like wireless keys often use lithium metal. However, conventional lithium-metal batteries are not rechargeable. Attempts to develop batteries that were rechargeable and relied on metallic lithium have historically faced considerable challenges. The batteries would often short-circuit, and they presented safety concerns.

Lithium-ion batteries are different. Note the introduction of the word “ion” here. These are not the same as lithium-metal batteries. In lithium-ion batteries, lithium ions intercalate or insert into and out of the anode and the cathode and the materials at the different ends of the battery. This intercalation allows these batteries to avoid the challenges associated with metallic lithium. Notably, the anode of these batteries is commonly made out of graphite, which is composed of flat sheets of carbon atoms. When you charge a lithium-ion battery, the lithium ions migrate into and sit between these sheets rather than combining with electrons and becoming lithium metal. This allows lithium-ion batteries to be recharged much more easily.

When lithium-ion batteries were introduced by Sony in the early 1990s, these batteries presented a major step up in performance compared to other rechargeable batteries at the time. They held much more energy in a given volume or mass of batteries, which was especially important for their initial applications in portable electronics. Portable electronics like video cameras and laptops and cellphones became increasingly popular and as you well know, consumers desired devices that lasted longer on a single charge. Therefore, researchers improved battery performance significantly, production increased substantially, and cost dropped dramatically.

Some of my and my colleagues’ recent research showed that over just about three decades, the prices of lithium-ion batteries declined by approximately 97 percent. In other words, batteries today cost less than 3 percent of what they cost three decades ago. Over the same time, lithium-ion batteries were also customized for use in a range of applications, from cellphones to power tools, eventually to vehicles and to stationary storage connected to the electric grid. This improvement in performance and decline in cost combined with that flexibility that allowed lithium-ion batteries to be customized for different applications, all of this led to their dominance.

Kristin Hayes: Why are people now looking for alternatives then? Maybe I should start that question by saying it certainly does seem like people are now looking for alternatives to something that, as you point out, has been tremendously successful and widespread and has had a lot of value. Why are we looking for alternatives now?

Micah Ziegler: It’s important to note that lithium-ion batteries are no longer composed of just a single combination of materials. Rather, the term lithium-ion now refers to a constellation of different materials. Over time, researchers have developed new electron materials that provide a variety of improvements. Some cathode materials, for example, replace some of the cobalt which was used in the original lithium-ion batteries with nickel and manganese. This can reduce cost and reliance on somewhat scarce cobalt while also increasing the amount of energy that can be stored. Meanwhile, other cathode materials were developed that rely on iron and can last longer and cost even less.

However, you’re right, people are still concerned about how and where these materials are mined and processed. Some metals for batteries, notably cobalt, are associated with human rights abuses. There are concerns about the environmental impacts of mining. Meanwhile, the processing of these materials is currently generally limited to a small handful of countries. There are also questions as to whether we can scale the mining and processing of these materials quickly enough to meet demand for our many energy storage applications, including electrifying cars and trucks, as well as supporting electric grids that are increasingly dependent on solar and wind resources. And of course, researchers and labs around the world are always on the search for better-performing, lower-cost options. Combined, these factors have driven a considerable search for alternatives.

Kristin Hayes: How does this affect the conversation about range, too? Certainly, you mentioned cost and the availability of materials a number of times. Are we looking for battery chemistries that might actually allow that longer range that seems to be a big part of the conversation around electric vehicles?

Micah Ziegler: Absolutely. We’re looking for new battery chemistries, new battery designs—ways to cut down on the weight and volume associated with all the components that go into supporting the batteries. Researchers at a variety of levels are trying to make sure we can essentially have electric vehicles that can travel as far as possible on a single charge.

Kristin Hayes: Some of the chemistries that I think are floating out there as near-term alternatives include sodium-ion batteries. I would love to talk about that. Then there’s also some talk about innovations in so-called “solid-state” batteries. I’m wondering, in the context of what we’ve been talking about around range and cost, can you just say a little bit about how those particular chemistries might show some promise?

Micah Ziegler: Sure. Let’s start with sodium-ion batteries. As the name implies, in these batteries, lithium is replaced with sodium, and there are other changes, too; for example, in the electron materials. In the commercial cells announced a few years ago, the cathode material relies on iron, and the anode material uses a different form of carbon. However, the fundamental process of the ions moving back and forth between and into and out of the electrodes when charging and discharging remains very similar to what we see in lithium-ion batteries. And these sodium-ion batteries are considered promising because of their reliance on less expensive, substantially more common elements. This leads to lower-cost batteries that might not face supply limitations.

However, the current generation of sodium-ion battery cells cannot store as much energy in a given mass or volume as can be stored by the best lithium-ion options. There are, interestingly though, some indications that sodium-ion batteries might perform better in lower temperatures.

Solid-state batteries, which you also mentioned, differ in another way. Notably, lithium-ion battery technologies today rely on a liquid electrolyte. The electrolyte is a solution that helps the lithium ions travel back and forth in the battery. Researchers are trying hard to replace this liquid with a solid electrolyte. Batteries with solid electrolytes could be safer and allow for a higher specific energy, for more energy to be held within a given weight of batteries. Notably, researchers hope that solid electrolytes might allow us to achieve the long-standing goal of safely using lithium metal in a rechargeable battery. Rechargeable lithium-metal batteries with solid electrolytes could allow us to substantially increase specific energy beyond what is seen in today’s lithium-ion batteries.

Kristin Hayes: Interesting. This leads me to something I’ve been very curious about. As this evolution of battery technologies is continuing, I’d love your opinion on whether you think we’ll end up with a multitude of battery chemistries across the globe, or do you think that one will eventually come to dominate, let’s say, at least temporarily, as lithium ions have done so far? I think about this not only in the context of electric vehicles and the development and deployment of those batteries, but you also mentioned a number of other applications. How do you think about that competition versus consolidation of chemistries over time?

Micah Ziegler: I suspect that, going forward, we’re going to see a diversity of battery chemistries that serve an even wider variety of applications, albeit with lithium still playing a major role. We’ve already seen diversification within the context of lithium-ion batteries and I expect that trend to continue. Lithium-ion batteries, as I’ve mentioned, can be made using different combinations of electrode materials to meet a range of performance and cost targets. Within this constellation of lithium-ion options, some battery chemistries store a lot of energy in these small, slim cells which we use in our laptops and our cellphones. Other chemistries and designs allow batteries to quickly release lots of energy—for example, in power tools—and still others balance the requirements for energy capacity and weight and power to allow electric vehicles to travel further and charge rapidly.

Due to the lightweight nature of lithium and its electrochemical characteristics, as well as the considerable head start that lithium-ion technologies have, I expect they will remain a major player in the battery space for at least a few decades.

I also suspect we will see some diversification outside of the lithium-ion space. As society works to electrify our energy systems, we’re going to need more options to store electrical energy for different applications. These options can be provided in part by a range of different battery chemistries and designs. For example, there are some battery chemistries being developed specifically for stationary storage to support the use of solar and wind power. In stationary applications, that lightweight nature of lithium is less relevant. There’s a prominent example: iron-air batteries. But how quickly these technologies will improve and scale versus lithium ion is still an open question.

Kristin Hayes: That’s actually a great lead into a bit of a conversation about your particular research that you mentioned at the beginning. Something that I think you’re really interested in is factors that actually influence technological change. How is it that some things develop more quickly and actually get into the marketplace, and what holds other things back? Maybe I can ask you a bit about that and why that’s a particular interest of yours, and maybe you could say a little bit, too, about how you research something like that?

Micah Ziegler: I really want to understand why some technologies succeed and others do not. What factors enable some technologies to improve and come down in cost rapidly? As we’ve seen for solar panels and batteries, why do other technologies stay relatively the same over time or sometimes even increase in cost? I believe that if we better understand these factors, we can help more sustainable technologies succeed. Hopefully, we can apply what we learn to improve the design of the next generation of technologies to enable them to improve rapidly. I also aim in this work to inform the design of policies and the direction of investment so they can enable the success of sustainable options.

To understand these factors, I collect a lot of empirical real-world data on technologies. What goes into these technologies? How much do these inputs cost? How are they manufactured? I try to collect data that describe how all of these change over time. Then, using models that reflect the underlying physics and chemistry and engineering, I can disentangle how various factors contributed to technological improvement. Essentially, we are quantifying the mechanisms of technological change. For example, using this approach, my colleagues and I have studied how changes in material performance and prices contributed to the rapid cost decline of lithium-ion batteries. We found that between the late 1990s and the early 2010s, the increase in cell charge density contributed more to cost decline than the decrease in the price of cathode materials. These results can inform the design and engineering of the next generation of batteries.

We also, in this work, estimated the contributions from high-level mechanisms of technological change, those often associated with policy and business decisionmaking, like research and development, learning by doing, and economies of scale. Using this approach, we found that over the same time period, the late 1990s to the early 2010s, research and development—both public and private—contributed more to the cost reduction of lithium-ion batteries than did economies of scale. These types of results can then inform the design of new public policies and how we direct financial investments.

Kristin Hayes: That is super interesting. I’d love to ask you to say just a little bit more about that in terms of what we’ve learned about batteries. How can policymakers come up with new policies that would really aim to accelerate some of this deployment that we really need either in the battery space or maybe in other sustainable technologies, too?

Micah Ziegler: My research suggests two major lessons for policymakers. The first emphasizes the importance of continued funding for research and development, and the second highlights certain technology designs that might enable rapid improvement.

As I mentioned earlier, in this research, my colleagues and I found that for more than two decades after the commercial introduction of lithium-ion batteries, public and private research and development played a very large role in cost reduction, while other factors like economies of scale contributed less. Other research found a similar result for solar photovoltaic modules—that research and development contributed substantially to cost reduction well after photovoltaics were introduced. These results suggest that if policymakers maintain funding for research and development for sustainable technologies even well after these technologies are introduced to the market, they could accelerate the improvement in deployment of these sustainable options.

It is important to note that policies that aim to stimulate demand and expand markets can also encourage private research and development, so market-expansion policies can complement those policies that more directly support public research and development efforts. In the case of lithium-ion batteries, we also found that access to a diverse range of chemistries might have enabled their rapid improvement and cost decline. As we’ve discussed, there are many different combinations of battery materials available that researchers discovered. Moreover, when researchers wanted to introduce an improved component, they didn’t need to reinvent how these batteries were designed and manufactured and operated every time an improvement was made.

This diversity of chemistries and the ability to easily integrate these many options into battery production might have contributed to the success of lithium-ion batteries. One implication of these findings is that investments, both public and private, might enable faster technological improvement if they support technologies whose designs allow different components to be easily incorporated without needing to reinvent the whole technology every time a component is improved. For storage technologies especially, the support could be combined with support for continued exploration of an array of chemistries.

Kristin Hayes: Very interesting. All right. I know we’re almost at the end of time. I do want to ask you one more substantive question and then of course, we’ll close with our regular feature, but that question is actually about battery recycling, which is something that we haven’t really talked about so far in our conversation today.

I wondered if you could say just a little bit about that particular topic, whether some of these chemistries in fact lend themselves more easily to recovery of materials and reuse of those materials. How important would you say innovation in that particular space around the reuse of materials is in comparison or alongside the development of these actual new chemistries themselves?

Micah Ziegler: I think both are important complementary investments in our future. Developing new chemistries can improve performance, lower cost, and as we’ve discussed, maybe reduce our reliance on any given set of materials. Developing our capacity to recycle batteries is also vitally important. We’re making many billions of lithium-ion battery cells a year, and building the capacity to recycle them can help ensure that the effort we put into mining and refining the materials doesn’t go to waste when batteries need to be replaced. We still have a lot to learn about how to recycle batteries efficiently and cost-effectively and how to ensure that the recycled materials are of the quality necessary to make new batteries.

However, the contribution of recycling to the supply of materials for new batteries is going to remain limited for years to come. This results from a lag between when batteries are produced and when they’re recycled. The batteries going into electric vehicles today will last for years and thus, the materials in them won’t be available to be recycled into new batteries for quite a while. In the meantime, we’ll still need materials to meet the growing demand for batteries.

Kristin Hayes: Fair enough. Having just obtained my electric vehicle, I can personally say I hope that battery lasts for many years, and you will not be seeing my lithium anytime soon.

This has been a great conversation. I really appreciate this introduction, and I hope folks have enjoyed as much as I have, learning about both the history and the future of what is, again, I would argue a really critical part of the EV revolution, if you will. Thanks.

We’ll close the recording with our regular feature, Top of the Stack. I think all of our listeners know what that is at this point. Micah, let me just ask you, what’s on the top of your stack?

Micah Ziegler: I have an eight-month-old daughter, so honestly, my stack is mostly composed of board books. The Very Hungry Caterpillar and All The World are really big hits.

When it comes to energy and sustainability, what I’m keeping an eye out for are articles and reports that describe community-engagement efforts around energy projects. I’m reading about local groups that support and oppose solar and wind projects and researchers’ efforts to interview stakeholders and understand their concerns. Transitioning our energy system to low-carbon options requires building many new things. Battery and EV factories, charging stations, mines, recycling facilities, solar and wind farms, transmission lines—these things will not be built in a vacuum. They’ll be built in and near communities, and the local officials who represent the people who will work and live near our existing and proposed energy infrastructure should be included as decisionmakers alongside project developers and regulators. Two-way communication and education between these decisionmakers is important, and effective community engagement can foster constructive relationships that extend beyond an individual project or proposal.

This is really challenging work, and one-size-fits-all approaches seem to be few and far between, but it’s important work, so that’s why I’m paying attention to it.

Kristin Hayes: Great. All right. Well, hopefully, we’ll have more opportunities to talk here on Resources Radio about that topic, because I agree with you, it is a really important and interesting space to understand how best to move forward.

Thanks again, Micah. It’s been a pleasure to talk with you.

Micah Ziegler: Thank you so much. I enjoyed our time.

Kristin Hayes: You’ve been listening to Resources Radio, a podcast from Resources for the Future, or RFF. If you have a minute, we’d really appreciate you leaving us a rating or a comment on your podcast platform of choice. Also, feel free to send us your suggestions for future episodes.

This podcast is made possible with the generous financial support of our listeners. You can help us continue producing these kinds of discussions on the topics that you care about by making a donation to Resources for the Future online at rff.org/donate.

RFF is an independent, nonprofit research institution in Washington, DC. Our mission is to improve environmental, energy, and natural resource decisions through impartial economic research and policy engagement. The views expressed on this podcast are solely those of the podcast guests and may differ from those of RFF experts, its officers, or its directors. RFF does not take positions on specific legislative proposals.

Resources Radio is produced by Elizabeth Wason, with music by Daniel Raimi. Join us next week for another episode.