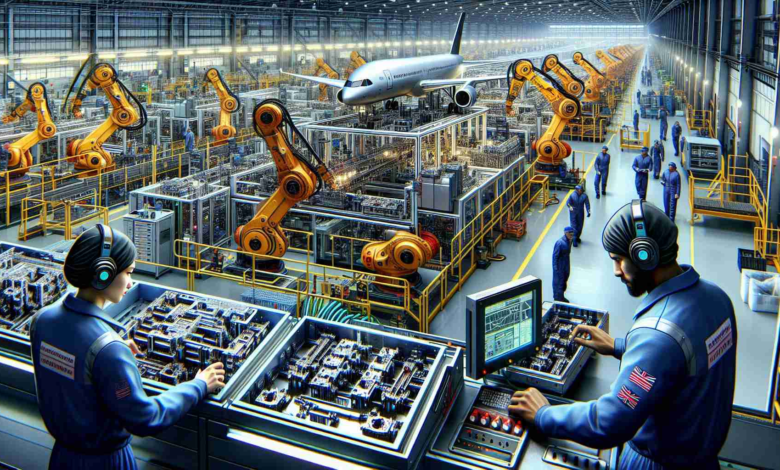

Large-Scale Robotics Enhance Aerospace Manufacturing in the UK

Summary: UK-based Loop Technology has partnered with FANUC to enhance aerospace manufacturing capabilities through the acquisition of the UK’s largest industrial robots. These robots will contribute to Project Compass, a significant aerospace R&D project aiming to accelerate manufacturing processes.

In a pioneering move to amplify their aerospace manufacturing capabilities, Loop Technology has entered into a significant agreement with robotics giant FANUC. The deal comprises the procurement of seven cutting-edge robots, four of which are the M-2000iA/1700L model – distinguished as the mightiest long-reach industrial robots that the UK has ever utilized.

This transaction underscores a broader initiative known as Project Compass, which focuses on advancing composite manufacturing in the aerospace sector. The University of Sheffield’s Advanced Manufacturing Research Centre (AMRC) stands as a central player in this project and will house three of these formidable six-axis robots at their new South Yorkshire innovation hub. The expansive £80 million investment underlying Project Compass brings together a coalition of industry leaders including Boeing, Spirit AeroSystems, and the AMRC itself.

The deal is not limited to the AMRC, but extends to North American aerospace sectors as well. Loop Technology has also secured additional robots for the development of a high-rate composite preforming cell, which will serve their transatlantic client’s manufacturing needs. With this venture, Loop Technology is set to cement its status as a global trailblazer in the application of industrial automation for aerospace production.

Enhancing Aerospace Manufacturing Through Robotics

The aerospace industry is witnessing a substantial transformation fueled by technological advancements, and the acquisition of large-scale industrial robots by Loop Technology underscores this evolution. The partnership with FANUC positions Loop Technology at the forefront of innovation in aerospace manufacturing.

Market Forecast and Industry Trends

The global aerospace robotics market is on an upward trajectory, and forecasts suggest a significant expansion in the coming years. The increasing demand for aircraft, coupled with the pressing need to expedite production processes while maintaining high-quality standards, presents ample growth opportunities for robotic solutions within the aerospace sector. According to market research, the integration of robotics in aerospace production is expected to enhance efficiency, reduce manufacturing time, and minimize costs.

One key factor driving the adoption of robots is the ever-growing composite materials market within aerospace applications. Composite materials are favored for their reduced weight and superior strength, which significantly improve aircraft performance and fuel efficiency. Consequently, robotic systems that can handle these advanced materials are increasingly sought after, making initiatives like Project Compass particularly pertinent.

Industry Issues and Challenges

While the integration of robotics in aerospace has numerous benefits, there are also challenges to be addressed. One such issue is the need for skilled labor to operate and maintain these advanced robotic systems. The industry faces a skills gap as it requires a workforce that is adept both in robotics and aerospace manufacturing complexities.

Moreover, stringent safety and quality standards in aerospace create a need for precise and reliable robotics solutions that can consistently achieve compliance. Companies must navigate these regulatory landscapes to ensure that robotic integration not only advances manufacturing capabilities but also aligns with industry regulations.

As Loop Technology embarks on this ambitious project, its contribution spans across the Atlantic, indicating the global implications of automation in aerospace manufacturing.

For those interested in gaining further insight into the industry trends and market forecasts, you can visit reputable resources like the Aerospace Industries Association and Robotic Industries Association.

Loop Technology’s venture with FANUC demonstrates not only the potential of robotics in revolutionizing aerospace manufacturing processes but also the global cooperation necessary to push the industry forward, fostering innovation and efficiency on an international scale.

Michał Rogucki is a pioneering figure in the field of renewable energy, particularly known for his work on solar power innovations. His research and development efforts have significantly advanced solar panel efficiency and sustainability. Rogucki’s commitment to green energy solutions is also evident in his advocacy for integrating renewable sources into national power grids. His groundbreaking work not only contributes to the scientific community but also plays a crucial role in promoting environmental sustainability and energy independence. Rogucki’s influence extends beyond academia, impacting industry practices and public policy regarding renewable energy.