Manufacturing CRM Implementation: A Complete Guide

The manufacturing industry has undergone a revolutionary transformation in recent years. While transitioning from a distribution-centric model to a customer-centric approach, the sector has witnessed dramatic changes in its operations. One technological advancement that has proven to be instrumental in facilitating this digital transformation is Customer Relationship Management (CRM).

In the manufacturing industry, where time and customers are of utmost importance, manufacturing CRM implementation emerges as a game-changer that can efficiently revolutionize workflows and elevate customer relationship management.

Imagine a solution that not only keeps the wheels of manufacturing running smoothly but also adds a personalized touch to customer service. This is where the power of a manufacturing CRM systems implementation truly shines. It delves into intricate details—handling inventory, catering to client’s needs, and forecasting sales— all while seamlessly blending into your existing workflows. In essence, manufacturing CRM systems implementation is not just about innovation and efficiency; it is about making and maintaining customer connections.

The Impact of Manufacturing CRM Implementation

A Statista report indicates that revenue in the CRM software market is poised to reach a market volume of $88.19 billion by the end of 2024 and $131.90 billion by 2028, growing at a CAGR of 10.59% from 2024 to 2028. The average spend per employee in the CRM software market is projected to reach $25.14 in 2024. These statistics highlight why the implementation of CRM systems in manufacturing is critical to capturing market share and driving innovation.

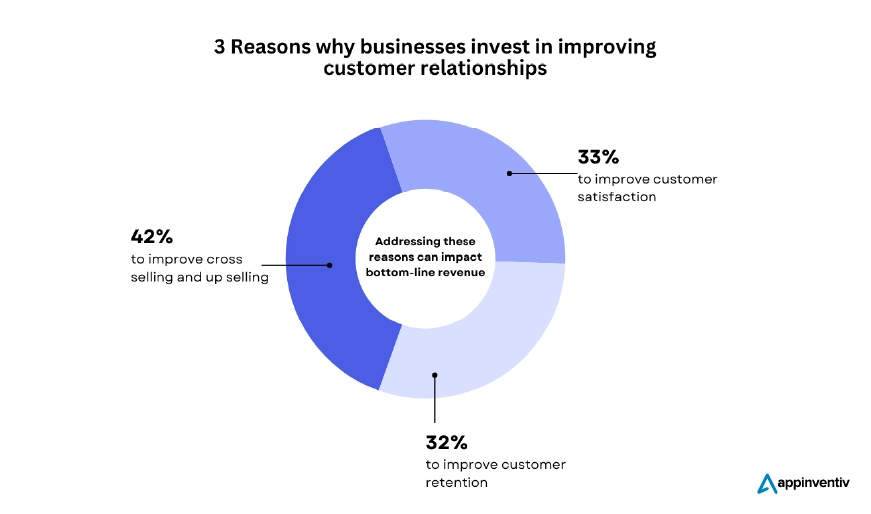

Here are some other reasons that indicate why CRM implementation in the manufacturing industry is essential:

Streamlined Operations and Processes

CRM implementation in the manufacturing industry can efficiently automate and streamline many manual processes, such as order management, inventory tracking, and customer support. By eliminating redundant tasks and improving workflow efficiency, manufacturers can reduce costs, minimize errors, and deliver products to market faster.

Enhanced Customer Relationships

One of the biggest reasons manufacturing businesses should implement CRM is to improve customer relationships. Customer satisfaction is a core component in driving business growth, as 86% of customers are willing to pay more for great customer service.

CRM allows manufacturers to build stronger and more personalized relationships with their customers. By centralizing customer data and interactions, manufacturers can better understand their customers’ needs, preferences, and purchase history. It enables them to tailor their products and deliver better customer services accordingly.

You may like reading: How AI in CRM Transforms Customer Engagement

Increased Efficiency and Productivity

Since a manufacturing CRM system automates all repetitive and rule-based tasks such as data entry, reporting, etc., it frees your employees to focus on more value-added activities. This boosts productivity and empowers employees to deliver better service and support to customers.

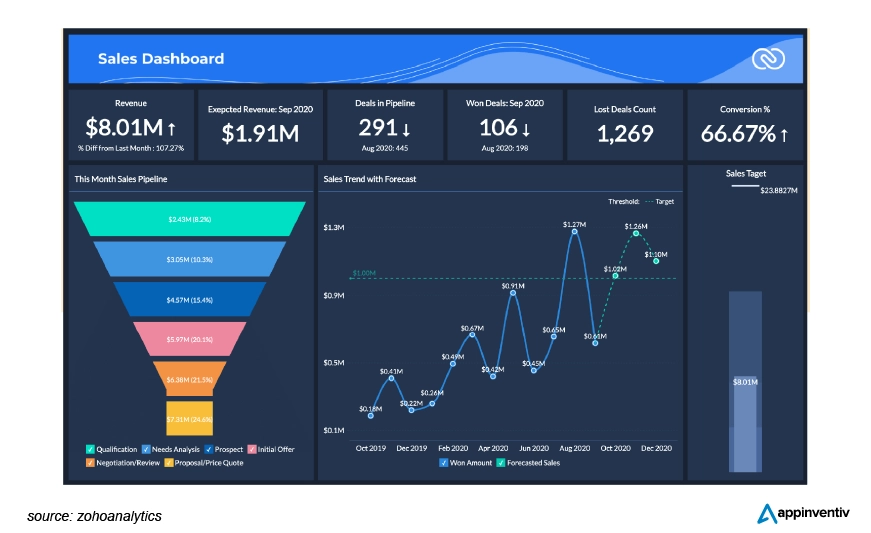

Improved Sales and Marketing Efforts

Manufacturing CRMs give businesses valuable insights into the sales pipelines, allowing you to automatically track leads, opportunities, and sales activities more effectively. With this information, manufacturers can redefine their sales and marketing strategies, target the right prospects, and nurture leads through the sales funnel.

You can even set the manufacturing CRM software to notify sales and marketing when a lead moves forward in the pipeline or hits a milestone, eliminating communication delays and mistakes.

Data-Driven Decision-Making

Data-Driven Decision-Making

Manufacturing CRM systems collect and analyze vast amounts of customer data, providing manufacturers with actionable insights into customer behavior, market trends, and product performance. By leveraging this data insight, you can find areas of improvement, identify new business opportunities, make informed decisions, and gain competitive advantages.

Scalability and Growth

As manufacturing companies expand and diversify their product lines, manufacturing CRM software provides a scalable platform to manage and nurture customer relationships across different markets and channels. This scalability enables you to adapt to changing business needs, enter new markets, and fuel long-term growth.

Improved Product Quality

CRM software development enables manufacturers to capture and analyze customer feedback and product performance data more efficiently. A feedback mechanism makes it easy to identify customer pain points and cater to their needs more effectively. By monitoring quality metrics and knowing issues early in the production process, manufacturers can take proactive measures to improve product quality, remove defects, and enhance customer experience.

Accurate Demand Forecasting

As a manufacturer, you often face the challenges of overstocks or stockouts. Overstocking costs extra money and product wastage, while stock outs cause you to lose valuable deals and customers. Manufacturing CRM systems implementation helps better predict what your customers want and when, balancing production and demand to protect your bottom line.

CRM systems leverage historical sales data, market trends, and customer insights to forecast current demand and future sales. By predicting current and future demand more precisely, you can optimize inventory levels, minimize stockouts and overstock situations, and ensure timely production and delivery of products to meet customer demand.

Enhanced Supply Chain Visibility

From sourcing raw materials to delivering the final products to customers, manufacturing CRM software provides end-to-end visibility into your supply chain management. By tracking supplier relationships, inventory levels, and production schedules in real time, you can identify bottlenecks, reduce risks, and optimize supply chain operations for greater efficiency and cost-effectiveness.

Related Article: Salesforce Integration Solutions – A Comprehensive Guide

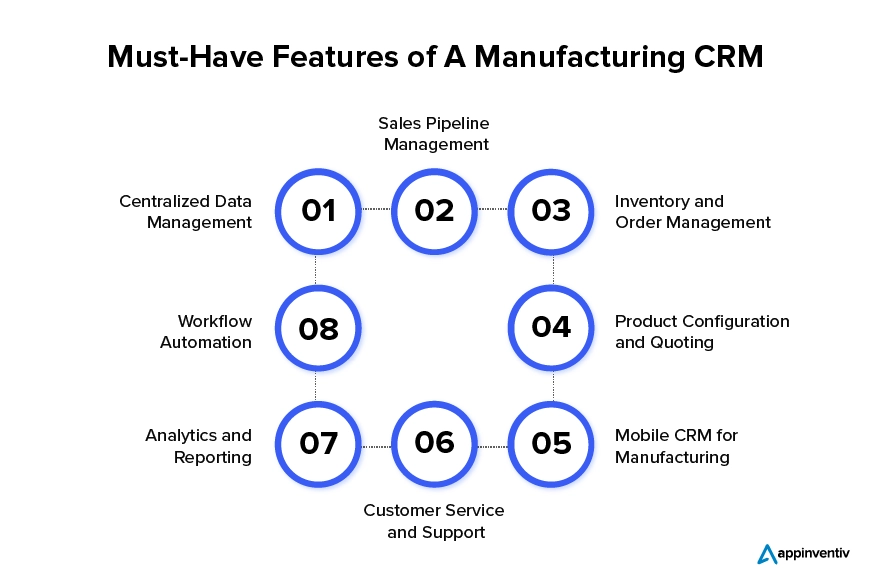

Key Functions & Features of Manufacturing CRM Systems

A custom CRM in the manufacturing industry encompasses a library of features and functions that add value to your business. Below are some essential features that will maximize the impact of a CRM in manufacturing.

Centralized Data Management

Manufacturing CRM software should be capable of centralizing customer data, making tracking customer behavior, purchase history, and interactions easier. Your sales and marketing team can use this centralized customer information to predict customer needs, personalize communication, and improve sales/marketing strategies.

Sales Pipeline Management

CRM systems should have features to manage the sales pipeline, including lead tracking, opportunity management, and quotation generation tailored to the manufacturing sales process. This feature helps you focus on the most profitable leads, contributing to your revenue operations.

Inventory and Order Management

It is one of the most important features of manufacturing CRMs, helping manufacturers manage orders and inventory levels. Knowing your inventory ensures timely product fulfillment, reduces stockout risk, and streamlines order processing.

Product Configuration and Quoting

CRM features uniform quoting capability and retains quote information within the system. You can use this information to configure complex products based on customer requirements and generate accurate quotes that reflect pricing, discounts, and customizations.

Mobile CRM for Manufacturing

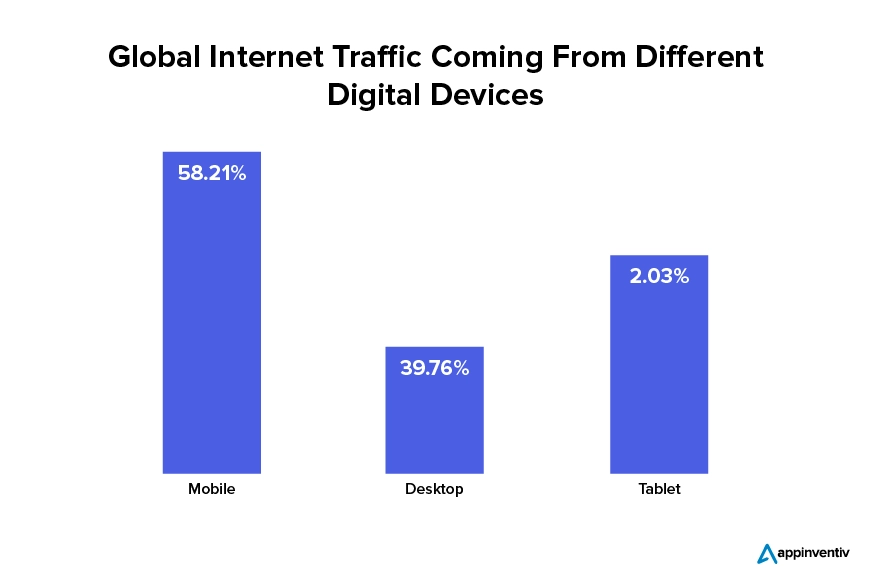

Mobile CRM is considered a best practice for improving customer experience in today’s digital age. Since around 59% of global internet traffic now comes from mobile, it is no surprise that mobile CRM is essential for manufacturing businesses.

Mobile-friendly interfaces or dedicated mobile CRMs enable sales representatives and field service technicians to access CRM data and functionality even on the go, improving productivity and responsiveness.

You may like reading: Mobile Application Development for Businesses

Customer Service and Support

CRM for manufacturing should have a tool that can provide a 360° view of customer interactions. Your customer service teams can access this information in real-time to manage customer inquiries and address issues remotely. This feature leads to higher customer satisfaction and retention rates.

Analytics and Reporting

Analytics and reports are the lifeblood of your manufacturing business. Thus, a CRM for manufacturing must have advanced analytics and reporting features to track key performance indicators (KPIs), analyze sales trends, forecast demand, and gain insights into customer behavior.

Workflow Automation

One of the most important features of manufacturing CRM is the ability to automate your workflow. Automation of repetitive tasks, such as lead nurturing, order processing, and follow-up communications, allows your teams to focus on higher-value activities.

Also Read: Business process automation – Top use cases and benefits

Best Practices for Implementing Manufacturing CRM

Manufacturing CRM is an advanced system that helps businesses improve customer service, sales, and marketing operations. However, simply implementing CRM in the manufacturing industry is not the right approach to getting the most out of your CRM investment. You need to follow a step-by-step process to ensure successful integrations of manufacturing CRM.

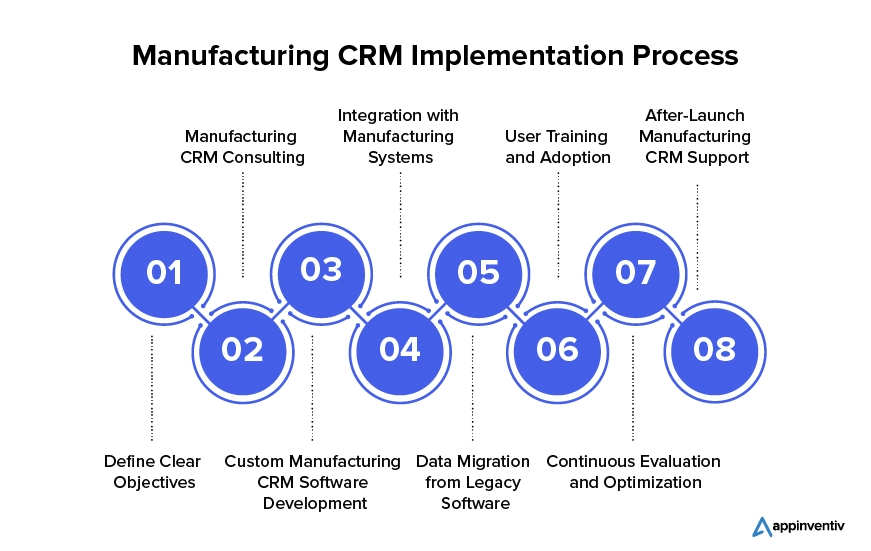

Let’s explore the best practices and key steps for manufacturing CRM implementation.

Define Clear Objectives

The first step in manufacturing CRM integrations is to set clear objectives. This initial step sets the foundation for the entire process, guiding subsequent decisions and actions. What do you want to achieve with custom manufacturing CRM software development and integration? Do you want to generate more leads, increase sales, or improve customer service? Once you know your goal, you can better leverage a CRM system to supercharge your growth strategy.

Manufacturing CRM Consulting

While defining objectives is crucial, navigating the complexities of CRM implementation often requires expert guidance. This is where manufacturing CRM consulting comes in. An experienced CRM consulting company like Appinventiv can provide valuable insights, helping businesses align their CRM strategy with broader organizational goals.

Custom Manufacturing CRM Software Development

Once you have a manufacturing CRM consulting partner in place, the next step is custom CRM software development. While the market has many off-the-shelf CRM solutions, they may not completely meet your unique requirements. Custom manufacturing CRM software development ensures the system is tailored to your organization’s unique workflows, processes, and goals.

Integration with Manufacturing Systems

Manufacturing CRM systems must seamlessly integrate with other key business systems such as MES (Manufacturing Execution System), PLM (Product Lifecycle Management), ERP (Enterprise Resource Planning), and accounting software. Integration enables data synchronization and streamlines processes across departments, enhancing efficiency and collaboration.

Data Migration from Legacy Software

Transitioning critical information from legacy systems to a new CRM platform requires careful data migration. This process must be handled with precision to ensure data integrity and continuity of operations. Partnering with an efficient tech provider experienced in data migration and CRM development services can ensure a smooth transition.

User Training and Adoption

Even the most advanced CRM system is only effective if users know how to utilize it. Therefore, comprehensive user training programs are essential to ensure successful adoption and maximize the system’s benefits. You must educate users on how to use the manufacturing CRM system, encouraging their active participation and engagement.

Continuous Evaluation and Optimization

Once your CRM system is up and running, you must continuously monitor and measure its results. This will help you evaluate whether the system meets your goals based on various metrics, such as improved customer satisfaction, increased sales, and reduced costs.

After-Launch Manufacturing CRM Support

Last but not least, opting for post-launch support and maintenance services ensures the ongoing success of your manufacturing CRM software. It helps you promptly address any issues, bugs, or user queries. This proactive support ensures smooth operations and maximizes the value derived from your manufacturing CRM implementation over time.

You may like reading: How Mobile Application Maintenance is a Key to Your App’s Success?

Challenges and Solutions in Manufacturing CRM Implementation

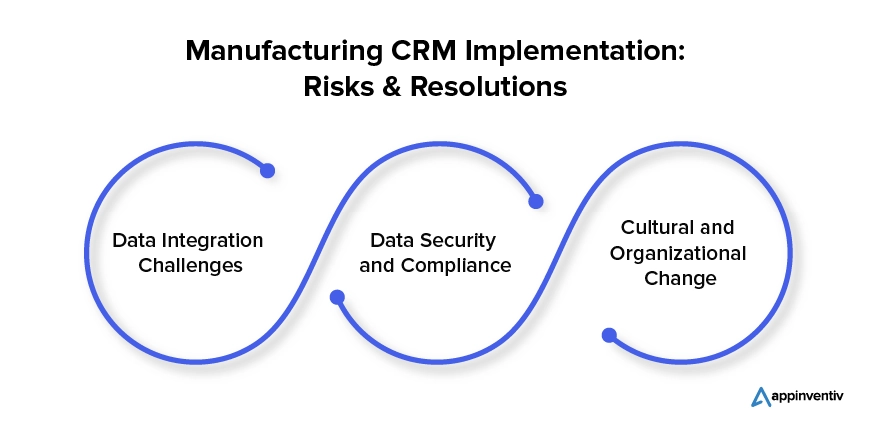

CRM implementation in the manufacturing industry involves critical challenges requiring strategic solutions. Let’s explore common challenges manufacturers face and provide practical solutions to overcome them.

Data Integration Challenges

Challenge: Manufacturers often deal with disparate data sources scattered across different systems, platforms, and departments. This makes consolidating and integrating data into a unified CRM platform challenging.

Solution: You need to invest in robust data integration tools that facilitate seamless data exchange between CRM systems and existing enterprise systems. Also, you should implement data standardization processes to ensure accuracy and consistency across all data sources.

Data Security and Compliance

Challenge: Data security is a prime concern in every industry, and manufacturing is no exception. Protecting sensitive customer data from cyber theft or breaches while adhering to data protection laws can be challenging when adopting manufacturing CRM trends.

Solution: You need to develop a custom manufacturing CRM system with stringent security measures such as encryption, access controls, and regular security audits. Also, ask the development team to adhere to compliance and regulatory standards such as GDPR, WCAG, etc.

Cultural and Organizational Change

Challenge: Manufacturing CRM integrations requires cultural and organizational change. Employees may resist adopting new CRM systems due to fear of change, lack of understanding, or perceived disruptions to existing workflows.

Solution: Foster a culture of collaboration, innovation, and continuous improvement by providing comprehensive training to ensure a smooth transition. Educate employees about manufacturing CRM benefits, involve them in the decision-making process, solicit feedback, and reward employees for embracing change and contributing to its success.

Also Read: Industry 5.0 – Revolutionizing the Factory Floor with Human-Centric Manufacturing

Embark on Your CRM Development and Implementation with Appinventiv

Choosing to develop and implement a CRM in the manufacturing industry is a decision that can greatly impact your ROI and business growth. With manufacturing CRM systems implementation, you can efficiently automate repetitive processes, drive innovation, and enhance customer service, resulting in improved customer experience, retention rate, and sales.

Unsurprisingly, the impact of a CRM in manufacturing is vast and growing. So, if you are looking for a trusted tech partner for custom manufacturing CRM software development or implementation, Appinventiv is here to help.

Being a trusted provider of CRM development services, we can help you navigate the complexities of custom CRM development and implementation with confidence and security. Our team of 1500+ tech professionals will stand by you through every step of the manufacturing CRM implementation process, from defining clear objectives to providing post-launch support and maintenance.

Whether you want to automate sales processes, improve customer service, or gain actionable insights from data analytics, we have proven expertise and experience to help you achieve your goals.

Interested in manufacturing CRM implementation or development? Partner with us now!

FAQs

Q. What is a CRM for manufacturing?

A. A CRM for manufacturing is a software solution designed specifically to help manufacturing companies manage their relationships with customers and prospects. It enables manufacturers to track and analyze customer interactions, streamline sales processes, manage orders and inventory, and provide better customer service. By centralizing customer data and automating key processes, CRM systems help manufacturers improve efficiency, enhance customer relationships, and drive business growth.

Q. What are the different types of manufacturing CRM systems?

A. There are three types of manufacturing CRM systems:

- Operational CRM systems: These focus on streamlining daily operations like sales, marketing, and customer service. They help manage customer interactions and support smooth workflows.

- Analytical CRM systems: These are all about digging into data. They analyze customer information to uncover trends and insights that can drive better business decisions and strategies.

- Collaborative CRM systems: These systems aim to enhance communication and collaboration among different departments. By sharing customer data and insights, they ensure everyone is on the same page, enhancing overall customer satisfaction and efficiency.

Q. Why is it important to implement manufacturing CRM systems?

A. CRM implementation in the manufacturing industry is essential for several reasons, including:

Enhanced Customer Relationships: CRM systems enable manufacturers to build stronger relationships with customers by understanding their unique needs and delivering personalized experiences.

Improved Sales and Marketing: Implementing CRM in the manufacturing industry streamlines sales and marketing processes, leading to more targeted and effective campaigns.

Workflow Automation: Manufacturing CRM implementation automates repetitive tasks and processes. It helps improve efficiency and productivity in manufacturing operations while freeing up employees to focus on more value-added activities.

Data-Driven Decision-Making: Advanced analytics and reporting capabilities of a manufacturing CRM provide valuable insights into customer behavior and market trends. It enables manufacturers to make informed decisions.

Q. What is the cost of manufacturing CRM development?

A. The cost of manufacturing CRM development varies significantly based on several factors, such as the complexity of features, location of the development team, platform compatibility, technology stack, integration with existing systems, and so on.

Typically, the cost of manufacturing CRM development ranges from $30,000 to $300,000 or more, depending on your unique project requirements. It is essential to discuss your project idea with a reputable CRM development company to get a detailed quotation of timeline and cost estimate tailored to your specific needs.

Q. What are the emerging manufacturing CRM trends?

A. There are several trends shaping the landscape of manufacturing CRM systems implementation, each aimed at enhancing efficiency, improving customer relationships, and driving growth. Some of the most influential manufacturing CRM trends include:

AI and ML Integration: Businesses should leverage AI and ML for predictive analytics and personalized customer experiences.

IoT Integration for Predictive Maintenance: The trend of integrating IoT devices with CRM systems allows manufacturers to monitor equipment performance, predict maintenance needs, and proactively address issues before they escalate.

Enhanced Mobility and Remote Accessibility: One of the most prevalent trends for manufacturers is using mobile CRM solutions for remote work and field service operations.

Cloud-Based CRM Solutions: Cloud-based CRM solutions are gaining traction in the manufacturing industry due to their scalability, flexibility, and cost-effectiveness.It ensures business continuity and future growth.

Data Security and Compliance: With the growing importance of regulatory compliance and data privacy, manufacturing businesses must prioritize data security and compliance adherence when implementing CRM.

Advanced Analytics and Business Intelligence: Utilizing advanced analytics tools for deeper insights into sales performance and customer behavior.

THE AUTHOR

Sudeep Srivastava

Co-Founder and Director