Mishima Kosan partners with Ready Robotics to implement ForgeOS for simulation testing on the Nvidia Isaac Sim – Robotics & Automation News

Mishima Kosan, a diversified company with a strong presence in steel production, product manufacturing, and engineering services, has formed a strategic partnership with Ready Robotics, a pioneer in no-code software for industrial automation.

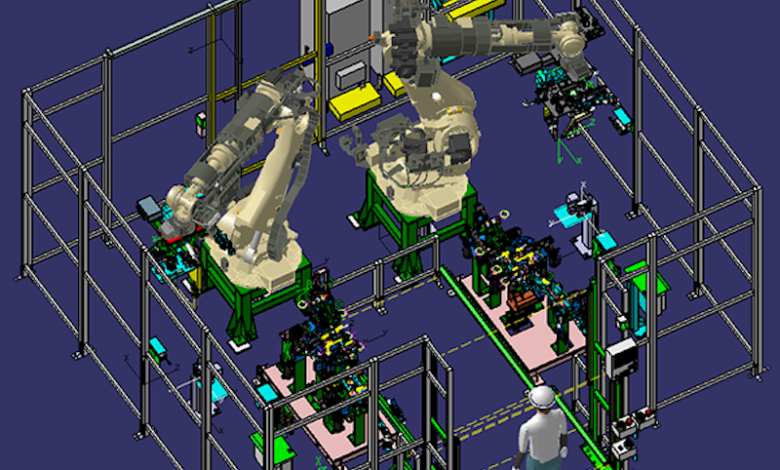

Through this collaboration, Mishima Kosan will deploy Ready Robotics’ ForgeOS, an innovative low-code/no-code platform that enables users to easily program and control robots and automation devices, in conjunction with Nvidia Isaac Sim, an extensible robotics simulation platform that gives users a faster way to design, test, and train AI-based robots.

By partnering with Ready Robotics, Mishima Kosan aims to enhance its automation capabilities with simulation and provide even more advanced solutions to its clients across various industries, including steel works, chemical plants, auto glass, and building materials factories.

The low-code/no-code nature of ForgeOS will empower Mishima Kosan’s team to quickly and efficiently develop and deploy automation solutions.

Yoshifumi Mizomoto, executive officer of Mishima Kosan, says: “We are pleased to partner with Ready Robotics and leverage their ForgeOS platform.

“As we continue our own industrial automation journey, we look forward to collaborating with Ready Robotics.

“The low-code/no-code capabilities and robot-agnostic control of ForgeOS, combined with the ability to simulate and test automation workflows using Nvidia Isaac Sim, will offer a significant advantage in delivering innovative solutions and driving the future of automation in Japan and beyond.”

ForgeOS, developed by Ready Robotics, is a device-agnostic, low-code/no-code platform that allows users to easily program and maintain automation systems, regardless of the brand of robot, sensor, or other hardware.

By integrating ForgeOS with Nvidia Isaac Sim, users can access virtual robots and simulate manufacturing lines from the comfort of a desktop computer without the need for specialized hardware or extensive programming knowledge.

Uniquely, ForgeOS allows for a bi-directional connection from simulation to the real workcell, meaning programs can be pushed easily from sim to real, while data and updates to the physical workcell can be pulled back to sim.

Kel Guerin, co-founder and chief innovation officer at Ready Robotics, says: “Our partnership with Mishima Kosan demonstrates the growing demand for accessible and user-friendly automation solutions.

“By combining the power of ForgeOS’ low-code/no-code capabilities with Nvidia Isaac Sim, we are enabling manufacturers to build and test automation workflows in simulation before deploying them in real-world environments, saving time and resources.”

As Mishima Kosan and Ready Robotics embark on this strategic partnership, powered by simulation tools from Nvidia, industries in Japan and worldwide can look forward to a future where automation is more accessible, efficient, and adaptable to the ever-changing needs of the market.