MIT engineers design breakthrough flexure for muscle-powered robots

Engineers at MIT have unveiled a spring-like device that promises to drive the next generation of muscle-powered robots

This feature, similar to a basic skeleton module, has the potential to become a universal blueprint for a variety of biohybrid bots, from walking and swimming machines to gripping mechanisms.

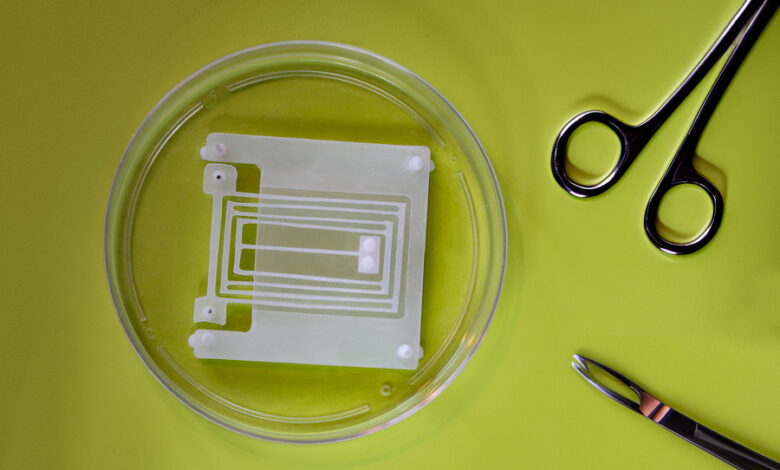

This new flexure represents a significant jump forward in the field of robotics. Their research, detailed in the journal Advanced Intelligent Systems, introduces a flexible structure that maximises the efficiency and range of movement achievable with muscle tissues.

Muscle powered robots

Muscles possess power and precision unmatched by synthetic devices. Using this potential for robotic applications has caused challenges due to the unpredictable nature of muscle contractions when not anchored properly. Raman and her colleagues set out to create a design that could reliably convert muscle contractions into precise and powerful movements.

The flexure can focus a muscle’s contraction along a specific direction, optimising the transfer of force into motion. This is achieved by ensuring the device is soft and flexible in one direction while stiff in others, effectively magnifying the muscle’s output.

When muscle tissue is attached to the flexure, it pulls on the spring-like structure with consistency and efficiency, stretching it up to five times more than previous designs.

Predictable and reliable

Unlike conventional muscle actuator setups, where muscles often produce erratic movements, the MIT flexure offers a predictable and reliable mechanism. By using precision-engineered flexures, robotics can now create muscle-powered robots with multiple degrees of freedom, enabling them to perform complex tasks with agility and control.

“These flexures are like a skeleton that people can now use to turn muscle actuation into multiple degrees of freedom of motion in a very predictable way,” explains Ritu Raman.

Could robots perform surgical procedures?

With this flexible skeleton module as a foundation, engineers can construct a wide range of artificial skeletons tailored for various robotic configurations. By combining these flexures, they can design robots capable of performing tasks ranging from surgical procedures to delicate manipulations in environments where traditional robots struggle to operate.

One promising application highlighted by Raman is the development of small-scale surgical robots with enhanced strength, efficiency, and adaptability. These biohybrid robots, powered by natural muscles, could change minimally invasive procedures, offering greater precision and control inside the human body.

As the team continues to refine and expand upon their flexure design, the future of muscle-powered robotics appears increasingly promising. By using the outstanding capabilities of muscle tissues, these robots may unlock new boundaries in automation and healthcare.