Mitsubishi Electric leads Series B investment in Realtime Robotics – Robotics & Automation News

Realtime Robotics, a provider of collision-free autonomous motion planning software for industrial robots, has secured a strategic investment from Mitsubishi Electric.

This is the lead investment in Realtime Robotics’ recently opened Series B round.

Mitsubishi Electric was also a participant in the Series A round, and will be adding a senior representative to Realtime’s board of directors.

The funds will be used to support the refinement and scalability of the company’s revolutionary robot workcell optimization and runtime solutions, which significantly help engineers and manufacturers reduce costs and increase productivity.

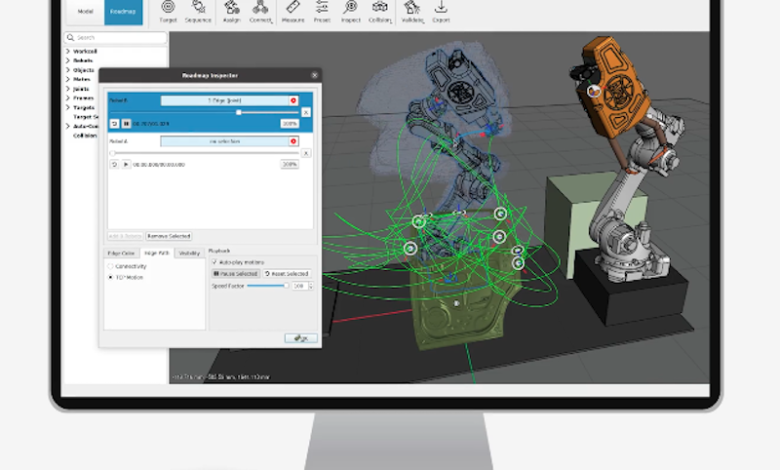

Realtime Robotics’ unique and innovative collision-free path planning technology provides solutions across the lifecycle of robotic workcells.

In iterative design stages, the award-winning multirobot optimization software rapidly generates and evaluates hundreds of thousands of possible solutions to identify the shortest cycle time.

Deployment and production are further simplified by runtime control, enabling multiple robots to work closer together, while simultaneously reacting to dynamic changes.

Finally, when the workcell needs to be retooled, the complex robot control is effortlessly reprogrammed for optimal cycle time from the first iteration.

Customers, including automotive manufacturers BMW and Volkswagen Commercial Vehicles, as well as integrators Valiant TMS and Schaeffler Group, report improved cycle times, reduced downtime, and increased throughput as a result of working with Realtime.

By increasing its stake, Mitsubishi Electric plans to further integrate Realtime’s cutting-edge motion planning technology into 3D simulators and other software to optimize manufacturing through the power of digital twins.

Later, Mitsubishi Electric expects to incorporate Realtime’s technology into factory automation (FA) control system devices, such as programmable logic controllers (PLCs), servo motors and computer numerical controllers (CNCs), to ensure uninterrupted plant operations by responding to needs for expanded automation capabilities, streamlined plant operations for improved efficiency, and fast responses to unexpected events.

Peter Howard, CEO of Realtime Robotics, says: “For years, industrial robot programming has remained a rigid, costly and labor-intensive process.

“Realtime is helping manufacturers realize the next wave of efficiency improvements necessary to get the most out of their new and existing automation applications.

“Our optimization and runtime technologies constitute a powerful Artificial Intelligence (AI) that operates much like the human brain’s motor cortex, efficiently managing multiple actions at the same time.

“Think of several cooks in a crowded kitchen being able to seamlessly work around each other to produce meals without error or collision. That’s the power of our technology.”

Realtime’s interfaces with leading simulation software brands and industry standard controllers help customers and partners access its powerful optimization and runtime solutions through their preferred method.

Howard says: “We will utilize these funds to accelerate the development of additional interfaces, driving toward full industry-wide accessibility in an increasingly user-friendly and efficient manner.

“Mitsubishi Electric understands manufacturers’ need to improve efficiency and productivity in the face of rising costs and diversifying customer needs. We’re thrilled to work closely with them to expand the use of our unique motion-planning technology.”