Multi-physics simulation and its relevance for the EV ecosystem • EVreporter

The new EV reality requires a major rethink for auto manufacturers, says Subham Sett, VP of Multiphysics Solutions Group, Hexagon Manufacturing Intelligence. In this interaction, he discusses the relevance of multi-physics simulation for the electric vehicle ecosystem.

What does multi-physics simulation mean, and what areas of EV and battery design and development can use it?

Multiphysics simulation refers to the simulation of different aspects of a physical system simultaneously to study the interactions among them. The ability to accurately simulate real-world physics behavior can help gain valuable insights and inform innovative designs. Multiphysics simulation tools can help OEMs test and validate designs virtually to reduce physical prototypes and improve product performance. This can help speed up innovation and increase the agility of the design process by optimizing designs across interacting physics to improve performance and efficiency.

This is particularly valuable to the automotive industry, especially given the growing adoption of electric vehicles (EVs). Cars have typically been made to type on fixed assembly lines, but the new EV reality requires a major rethink for auto manufacturers. It requires both entirely new vehicle architectures and automotive OEMs to scale up production, accelerate innovation and time-to-market, vertically integrate the supply chain, and incorporate flexibility and automation into production.

For OEMs and suppliers, it is business critical that they quickly adjust their products to reflect both changing regulations and customer requirements. This is where digital transformation technologies become a game changer.

Can you give some examples highlighting the relevance simulation for batteries?

Batteries are critical to EV manufacturers’ commercial success because they represent 50% of the vehicle’s cost. Getting the design right while controlling costs is essential to producing a price-competitive end product. Quality plays a key role in the development of battery cell parts, such as electrodes and separators.

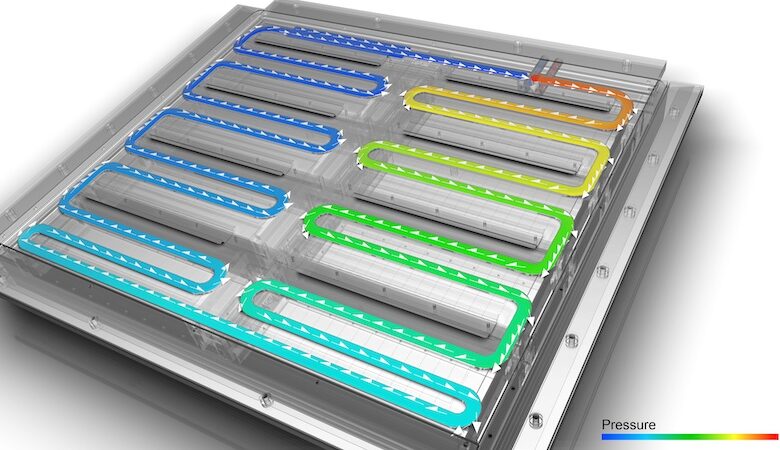

The production process for these parts must be designed to ensure non-contamination and non-defective products. Quality inspection must be specified to verify cells without damaging them. During design, manufacturers must also consider the thermal management of the battery system to ensure effective cooling as well as protect the battery units from damage in the event of any abuse to provide a safe, sustainable, battery-powered mobility solution. Our products can help manufacturers across all of these areas.

What is meant by a digital prototyping approach for product development?

Vehicle manufacturers today are under tremendous pressure to compress program duration. Development cycles have shrunk drastically from 48 months to 24 months or fewer.

Achieving such drastic reductions in development timetables demands that OEMs transition from unidirectional, waterfall processes to agile methods that can shift more CAE (computer-aided engineering) earlier in product development. This requires that they change their approach to how design tools are used and how groups collaborate. They must also leverage technologies such as Artificial Intelligence (AI) that facilitate more intelligent, efficient development. All these measures can help facilitate a move towards digital prototyping and reduced development cycles. As a result, this approach can also drive a shift towards substantial cost reductions during the design process.

How can Hexagon support local manufacturing of power electronics components?

The Electronics System Design and Manufacturing (ESDM) industry is one of the fastest growing in the world. Initiatives such as the Government of India’s Semicon India Program, with an incentive outlay of $10 billion, are set to position India as a global hub for semiconductor and display manufacturing.

For the industrial and power electronics sector, the focus is on improving performance and reliability at higher temperatures and higher voltages while reducing the size of products. Industrial and power electronics manufacturers are under pressure to innovate rapidly to assist in new sectors such as electric vehicles.

Our digital transformation solutions can help address these challenges by putting data to work in smarter ways, increasing efficiency and sustainability for industrial and power electronics.

Please tell us about Hexagon’s involvement and focus in the Indian EV ecosystem.

EVs have been one of the major growth areas for automotive players globally. Designing EV-specific subsystems, such as batteries, electric power trains, etc., has been a challenge for EV manufacturers, given that the industry is at a fairly nascent stage compared to IC engines. Several countries in Europe, etc., have already made great strides in innovating EV technologies and building the requisite ecosystems to facilitate adoption.

Hexagon has been working with automotive companies across the globe and has been able to bring this experience to Indian automotive companies by providing consultancy right from the design to the prototyping stage. Smart manufacturing can reduce this number (design to prototyping stage) to 10% or less, which is especially crucial for EV development. With our expertise and rich knowledge of best practices from automotive, electronics, and other key industries, Hexagon is equipped to make EV production easier, increasing productivity, lowering costs, and reducing time to market.

Our 100% EV program aims to accelerate the successful transition to electrification in the automotive industry. At the core of this is ensuring that batteries are safe. For instance, thermal runaway is a key issue that battery manufacturers deal with today. The battery pack’s design and application integration are crucial in preventing cell failure propagation. CFD tools such as Cradle CFD from Hexagon can help simulate various thermal upset conditions and assess the performance of the thermal management in avoiding thermal runaway.

This interview was first published in EVreporter May 2024 magazine.

Also read: India’s electric vehicle ecosystem | Policy updates in Mar 2024

Subscribe & Stay Informed

Subscribe today for free and stay on top of latest developments in EV domain.