New robotic gripper for automated apple picking developed

A robotic gripper developed by Washington State University researchers is able to gently grab the majority of apples out of a tree without damaging the fruit.

The innovative gripper is part of a robotic set-up that the researchers are hoping will someday do fruit picking and other farm chores for Washington farmers to help alleviate ongoing labor shortages. The researchers recently published their work on the gripper in the proceedings of the IEEE 7th International Conference on Soft Robotics.

“We’re hoping that we can help a lot of people with this project,” said Chris Ninatanta, a Ph.D. student in the WSU School of Mechanical and Materials Engineering and first author on the paper. “Labor shortages in Washington can be very hurtful to orchards.”

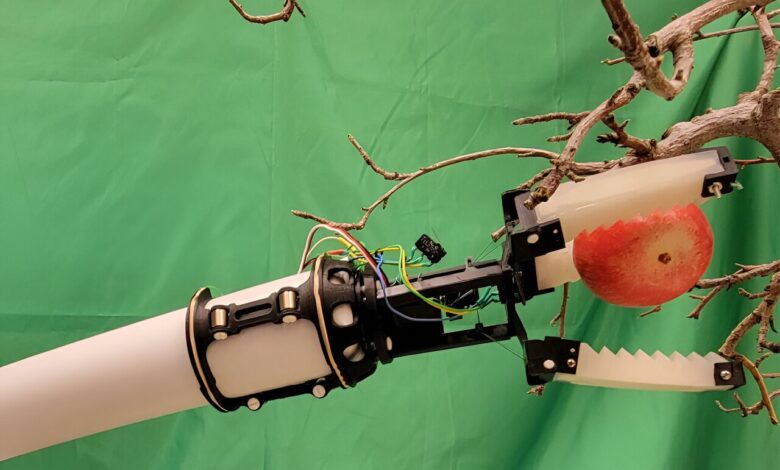

Weighing about two-thirds of a pound, the gripper uses three cables to move 3D-printed hard plastic and silicone rubber-tipped fingers. The fingers have to be gentle enough that they don’t damage the apples but strong enough to pull the apple off the tree. At a cost of about $30 to produce, the gripper includes a switch to grasp the apple and let go. It was able to successfully grab more than 87.5% of the apples in an orchard without damaging them.

“We’re always aiming to increase that with new designs,” said Ming Luo, Flaherty Assistant Professor in the School of Mechanical and Materials Engineering. Luo and Manoj Kakee, professor in Biosystems Engineering and director of WSU’s Center for Precision & Automated Agricultural Systems, led the work.

Washington state leads the nation in apple production, and in 2022, the industry contributed more than two billion dollars to the U.S. gross domestic product. Throughout Washington, farms employ anywhere from a dozen to hundreds of workers each year for orchard operations, including for pollination, pruning, flower thinning and fruit harvesting. With an aging population and a decrease in migrant farm workers, however, farmers have struggled to meet their needs for workers during harvest season.

In recent years, researchers have started developing robotic apple harvesting systems, but the ones that have been developed are expensive and complex to use in orchards.

Ninatanta, who grew up in Yakima, Washington, picked fruit alongside his parents during his childhood. When he began his work with Luo on a robotic apple gripper, he had his parents videotape their work, so he could model his gripper on their handiwork.

“So some of the design for this is actually inspired by my parents,” he said.

The WSU team will next connect their light-weight gripper to a low-cost robot system that they are developing. Similar to inflatable tube-people often used in outdoor advertising at car dealerships, the robot arm is made of a soft fabric filled with air that is similar but stiffer than the car dealership version.

As part of the project, the researchers are also working to add an onboard camera to their system that can precisely guide the arm as well as a gripper that can twist, similar to a human hand’s rotation to reduce the damage of the apple stem. They expect to try the system out in their lab and then farm fields later this year.

More information:

Chris Ninatanta et al, Design and Evaluation of a Lightweight Soft Electrical Apple Harvesting Gripper, 2024 IEEE 7th International Conference on Soft Robotics (RoboSoft) (2024). DOI: 10.1109/RoboSoft60065.2024.10521995

Citation:

New robotic gripper for automated apple picking developed (2024, June 13)

retrieved 13 June 2024

from https://techxplore.com/news/2024-06-robotic-gripper-automated-apple.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.