Nio exec explains how its factories use humanoid robots

Nio assembled a humanoid robot team in 2023 and has made two major attempts.

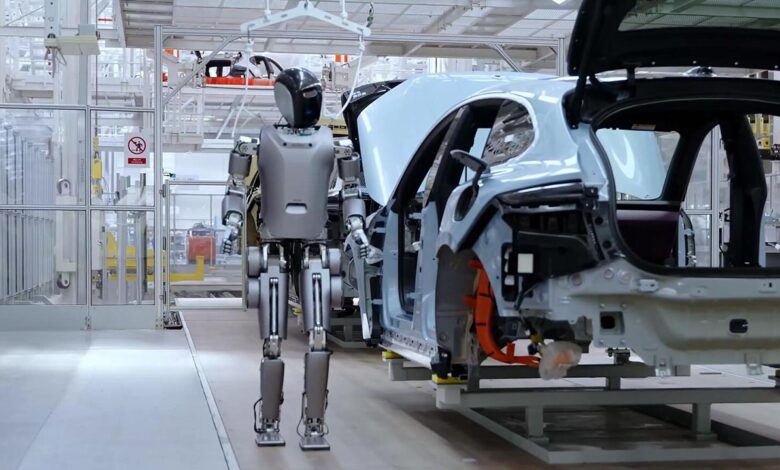

(A video screenshot shows a UBTech humanoid robot walking in a Nio plant.)

CnEVPost reported in late February that Nio (NYSE: NIO) was testing the use of humanoid robots on its factory production lines. Now, an executive at the electric vehicle (EV) maker has shared more details about the endeavor.

Based on its thinking and understanding of humanoid robots, Nio has assembled a humanoid robot “squad” in 2023, said Yi Peng, the EV maker’s head of humanoid robots for intellectual engineering.

Yi revealed the information at the China Humanoid Robot Ecology Conference 2024 in Shanghai earlier this month, explaining how Nio will use humanoid robots in its factories.

Nio has made two main attempts with humanoid robots, according to Yi:

Fixing humanoid robotic arms in tight spaces and multitasking with 5G and vision algorithms.

Using humanoid robots in some quality control processes.

On February 22, Hong Kong-listed humanoid robot maker UBTech Robotics (HKG: 9880) shared a video on Weibo showing its Walker S robot working on an assembly line at a factory of Nio.

In the training session, the Walker S utilizes its real-time image capture and transmission capabilities to participate in quality inspections of door locks, seat belts, headlight covers, and can affix vehicle identification, according to the video.

Nio’s vehicles are produced at its F1 and F2 plants in Hefei, in eastern China’s Anhui province, which were originally the assets of its automotive production partner, Anhui Jianghuai Automobile Group, but were acquired by the company late last year.

Both plants have highly automated production lines, and CnEVPost visited the F1 plant in December 2020 and the F2 plant in November 2023.

Nio completed the integration of the humanoid robot with the tools of the production system and utilized the humanoid robot’s on-board visual sensors to capture the appearance of the vehicle and use algorithms to judge the quality of the images for quality control, according to Yi.

Traditional industrial automation in the automotive sector has struggled to address the increased demand for smart manufacturing in automobiles, according to Yi.

However, humanoid robots, which are integrated tools with human form and intelligence, have a greater potential in automotive manufacturing for the replacement and automation of hazardous operations, he said.

Humanoid robots also offer new solutions in dealing with increasing labor costs in the global automotive industry, according to Yi.

“We believe that the scaled application of humanoid robots can facilitate the transformation of the automotive industry towards intelligence, globalization and decarbonization,” Yi said.

Nio focuses on the underlying technology of humanoid robots, including algorithms, dynamic sensing, large models, and has conducted some research, he said, adding that the company is pushing the application of humanoid robots in automobile manufacturing.

With the help of humanoid robots, automotive manufacturing assembly lines, which inevitably require human involvement, are expected to be fully automated in the future, according to Yi.

Notably, Yi believes that it will take a long time for humanoid robots to achieve widespread adoption.

The commercialization of humanoid robots in automotive manufacturing can be divided into three phases — scenario-driven, efficiency-driven, and cost-driven, according to Yi.

In the scenario-driven phase, typical scenarios need to be found to provide opportunities to help humanoid robots iterate.

In the efficiency-driven stage, Nio will focus more on the system operation capability of humanoid robots, and more on the real value that humanoid robots create in real business.

In the cost-driven phase, the overall adoption scale of humanoid robots, including the level of embodied intelligence, will play a decisive role, according to Yi.

Yi believes that in automotive manufacturing, logistics handling, parts assembly, quality inspection are currently more appropriate scenarios for humanoid robots.

Nio testing use of humanoid robots on factory production line