Optimized Multisensory Interface for Precise Liquid Pouring by Robots

In a recently published article in the journal Actuators, researchers from the USA introduced an advanced multisensory interface for robots to pour liquids accurately. Their system offers detailed sensory feedback while allowing the robots to maintain the high visual precision needed for precise pouring tasks.

The research suggested using an optimization method to figure out the best way to match different feedback types with the senses, aiming to give the most useful feedback without overwhelming the user’s brain.

Background

Robot-assisted manipulation finds use in various tasks and environments like surgery, exploration, hazardous situations, and assistive technology. Yet, users relying on robotic manipulators lack direct sensory information like touch, temperature, and force feedback, which affects their interaction experience. Such sensory feedback can provide crucial details about manipulated objects, boosting situational awareness and decision-making during tasks.

Multimodal feedback interfaces may provide effective solutions to bridging this gap and have been explored previously in several applications. However, some studies suggest that certain combinations of modalities may counter-productively prove to be burdensome, and an optimal combination may be dependent on the task type, individual differences, and context. Hence, evaluative studies of multimodal feedback have yielded conflicting outcomes across the literature.

About the Research

In this paper, the authors developed a multisensory interface aimed at enhancing robot-assisted pouring tasks. This interface provides nuanced sensory feedback crucial for precise robot operation while managing the high visual demand inherent in such tasks. The study employed an optimization approach to determine the most effective combination of feedback properties and modalities, aiming to maximize feedback perception while minimizing cognitive load.

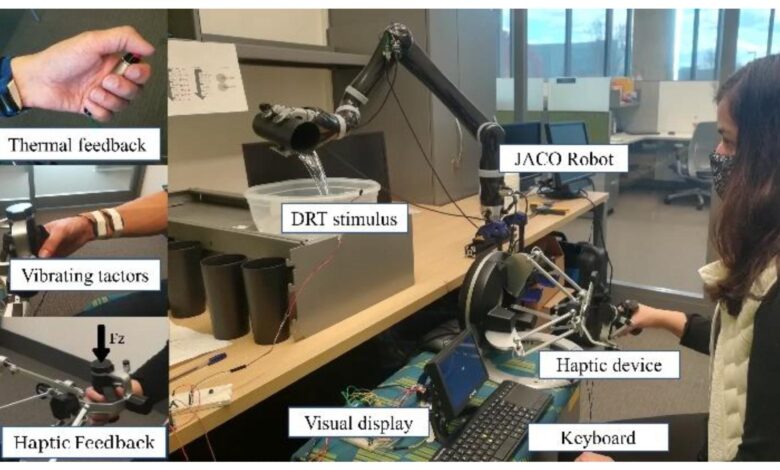

The presented system integrates various components, including a haptic device, a visual display, vibrating tactors, and a thermal feedback module with the robotic arm. These modalities provide information on temperature, weight, and liquid level properties during pouring tasks.

To optimize the interface, the researchers selected a set of metrics to model the cost, including resolution and perception accuracy, cognitive load measures, and subjective preference ratings. They utilized a linear assignment framework to derive the optimal mapping according to these metrics.

Furthermore, two experiments were performed to validate the effectiveness of the developed interface. The first one gathered data to generate a minimum-cost solution. The second experiment assessed the efficacy of this solution for decision-making tasks compared to a control case with no feedback and an arbitrary design. This comprehensive approach enables a systematic evaluation of the interface’s performance and its impact on task efficiency and user experience.

Research Findings

The outcomes of the first experiments revealed significant differences between modalities for perception accuracy, detection response task (DRT) hit rate, and subjective preference across all three properties. However, no significant differences were found in change response accuracy and DRT reaction time. Subjective preference, in particular, exhibited considerable variation among modalities, reflecting a range of factors worth considering.

To formalize these results, a cost function was defined, incorporating only the significant metrics identified from the screening experiments. The weights for these metrics were determined subjectively during the screening phase. The optimal solution, derived from this cost function, assigned liquid level feedback to vibration, weight feedback to audio, and temperature feedback to the visual display.

The second set of experiments demonstrated that the optimal solution significantly outperformed the control treatment of no feedback across all three metrics in the first and second use cases. Additionally, the tilt angle use case showed improvements in response time and subjective demand metrics compared to the control.

Furthermore, in comparison to the arbitrary design, the optimal solution performed better in success and subjective demand metrics in the temperature and empty vessel use cases, although these differences did not reach statistical significance.

Applications

The proposed interface can be applied to various scenarios where users need to remotely manipulate objects with different properties and make decisions based on sensory feedback. For example, the interface can be used for assistive technology to help individuals with disabilities perform daily living activities, such as making a drink or preparing a meal.

The interface can also be used for exploration or hazardous situations, such as handling hot or cold substances or liquids with different levels. The interface can enhance the user’s situational awareness, task performance, and user satisfaction.

Conclusion

In summary, the paper introduced an optimization approach for designing a multisensory feedback interface tailored for robot-assisted pouring tasks. Leveraging a linear assignment problem framework, the method produced a minimum-cost solution by considering metrics, such as feedback perception, cognitive load, and subjective preference. Results indicated that the developed feedback system significantly outperformed both the control case and an arbitrary design.

Moving forward, the researchers acknowledged limitations and challenges and suggested directions to further enhance the effectiveness and versatility of the interface in practical applications. They recommended expanding the scope by incorporating additional properties, modalities, and metrics, as well as conducting trials in more realistic and intricate task environments.

Journal Reference

Marambe, M.S.; Duerstock, B.S.; Wachs, J.P. Optimization Approach for Multisensory Feedback in Robot-Assisted Pouring Task. Actuators 2024, 13, 152. https://doi.org/10.3390/act13040152, https://www.mdpi.com/2076-0825/13/4/152