Robot designed to jump higher than Big Ben, even 200 meters on the moon

Researchers have designed a system that enables robots to record the highest-ever jumps.

A team at the University of Manchester has developed a design that allows robots to clear obstacles many times their size. They utilized a combination of computer simulations, laboratory experiments, and mathematical principles.

The system helped the team optimize the robot’s size, shape, and arrangement of parts and achieve the desired results.

According to researchers, the current highest-jumping robot can reach up to 33 meters, equivalent to 110 times its own size. The new robot can jump over 120 meters in the air or 200 meters on the moon—more than twice the height of Big Ben’s tower.

The details of the team’s research were published in the journal Mechanism and Machine Theory.

Efficient robot jumps

Traditionally, robots are designed to move by rolling on wheels or walking on legs. However, jumping is an effective way to navigate locations with uneven terrain or numerous obstacles.

Although jumping robots are currently on the market, their design presents a number of significant hurdles, the primary one being the ability to jump high enough to clear substantial and intricate barriers.

The team aimed to find a design that would “dramatically improve the energy efficiency and performance of spring-driven jumping robots,” said Dr. John Lo, Research Associate in Space Robotics at The University of Manchester and co-author of the study, in a statement.

The researchers discovered that conventional jumping robots frequently launch themselves before completely releasing the accumulated spring energy, which limits their maximum height and produces inefficient jumps. Additionally, they tend to waste energy by spinning or moving sideways instead of jumping straight up.

The researchers aimed to eliminate these undesirable movements with their new designs while maintaining the necessary rigidity and structural integrity.

Optimizing jump dynamics

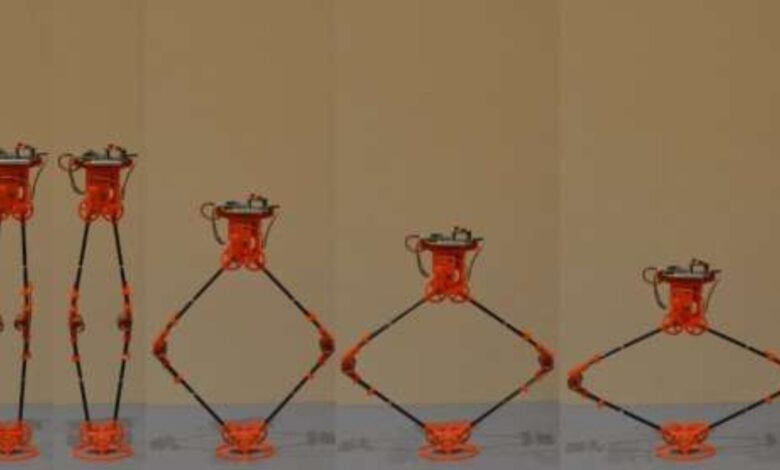

The team studied how prismatic and rotational spring-driven models jump and used this information to create a multibody model of a rhomboidal linkage for a physical jumping system.

According to the team, deciding on the robot’s shape involves choosing between leg-based propulsion akin to a kangaroo or a piston-like mechanism with a large spring.

Shape options range from simple symmetrical designs like diamonds to more complex, organic forms. The team then had to decide on the robot’s size: small ones are nimble, while larger ones can accommodate stronger motors for higher jumps. Finding the optimal size likely means striking a balance between agility and power.

The team’s design improvement involves redistributing mass towards the top and optimizing link structures, though these enhancements must be tailored to each design.

“Lighter legs, in the shape of a prism, and using springs that only stretch are all properties that we have shown to improve the performance and, most importantly, the energy efficiency of the jumping robot,” said Dr. Ben Parslew, Senior Lecturer in Aerospace Engineering at the University and the co-author of the study.

Although the researchers have identified a viable design alternative to significantly enhance performance, their next step is to control the direction of the jumps and determine how to utilize the kinetic energy from landing to increase the number of jumps the robot can perform on a single charge.

Researchers say they will also investigate smaller versions for space missions.

ABOUT THE EDITOR

Jijo Malayil Jijo is an automotive and business journalist based in India. Armed with a BA in History (Honors) from St. Stephen’s College, Delhi University, and a PG diploma in Journalism from the Indian Institute of Mass Communication, Delhi, he has worked for news agencies, national newspapers, and automotive magazines. In his spare time, he likes to go off-roading, engage in political discourse, travel, and teach languages.