Robotic-AI prototype a ‘first’ for tunnels

A consortium of technology and mechanical/civil engineering firms released new details on the ‘first’ robotic and artificial intelligence (AI) robotic solution for the installation of mechanical and civil services in on tunnels projects.

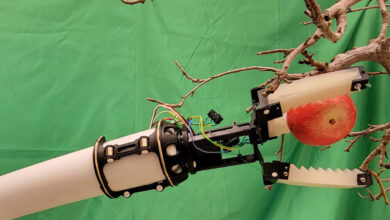

Named ATRIS (Automated Tunnel Robotic Installation System), the prototype can autonomously select brackets, locate their end location along a tunnel wall, and install them.

“In doing so, the automated solution can improve on-site health and safety by reducing the risks associated with manual labour at the tunnel work face,” said Costain, one of the companies involved with the venture. “For example; working at height in confined spaces, and hand-arm vibration experienced by workers during installation.”

Costain said traditional and manual execution of these services in tunnels has a higher degree of potential hazard, and can be more labour-intensive and time-consuming.

“Once fully developed, the final system can be deployed in tunnel construction for a variety of sectors including transport, water and energy,” added Costain. “It is expected to increase productivity by 40% due to faster installation, reduce installation costs for new mechanical and electrical systems by 30%, and cut construction plant movements by 40% to decrease embodied carbon.”

Robotic-AI tunnelling solutions for a difficult labour market

The prototype was also developed to help offset the challenges caused by a thin skilled labour market.

Steve Nesbitt, chief technologist for built environments at consortium member Manufacturing Technology Centre (MTC), said, “Like many sectors, construction has faced labour challenges over the past few years which has driven greater interest in using robots, beyond manufacturing and logistics, to address these issues.”

Nesbitt hopes further advancement in robotics and automation in the tunnelling sector could benefit the global segment.

“We are paving the way for construction companies to adopt technology for greater control and structuring of on-site works, making infrastructure delivery safer, more productive, and more sustainable,” he said.

About the ARTIS consortium

Five organisations in total – Costain, MTC, Tunnel Engineering Services (TES), i3D robotics (i3D), and VVB Engineering – are involved in ATRIS’ development, with all of the consortia headquartered in the UK.

Costain said that the 22-month project is partly funded by Innovate UK’s Smart grant, and led by TES, which developed the initial concept in partnership with the consortium. MTC spearheaded the design and manufacture of the robot’s end effectors, while i3D developed visualisation software for navigation. Costain and VVB provided industry knowledge and expertise in tunnelling and fit-out requirements.

Lee Bateson, mechanical and engineering manager and robotics lead at Costain, said of the initiative, “Teaching the robots to learn seemingly simple tasks – such as how to avoid cross-threading the screws that go into the sockets – has been hugely fulfilling, thanks to the consortium’s collaborative spirit.

“This is transformative technology that will have enormous benefits for the customers that we build tunnels for.”