secret to leading Japanese logistics solution vendors

The rush to embrace smart technology in the manufacturing and logistics industries means that smart warehouse systems are an increasingly common sight in factories and warehouses. Smart conveyor belts, smart pallets, autonomous mobile robots (AMR), as well as automated handling systems such as robotic arms with integrated AI visual recognition technology are becoming widespread. The traditional paradigm of manual picking, sorting, and handling has been gradually rendered obsolete. The boost in operational efficiency has been accompanied by a reduction in dependence on human resources as well as fewer occupational injuries.

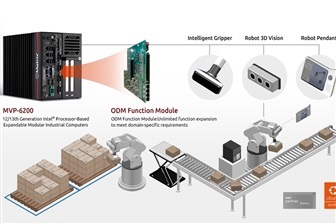

Growing demand for smart warehousing has spurred the emergence of related start-ups looking to capitalize on these new business opportunities. A certain start-up in Japan for example leveraged its innovative motion control software and algorithm to incubate an acclaimed smart robotic arm that has since been adopted by smart warehouse projects in Japan, America, and Europe. After careful assessment, the Japanese company decided a little over two years ago to introduce ADLINK’s MVP-6200 fanless embedded computer as its robotic arm controller.

Proprietary AFM Design Supports High Level of Customization and Expandability

Taita Chou, ADLINK’s Senior Product Manager of Edge Computing Platforms BU explained that there were several reasons why MVP-6200 was given the nod. Firstly, ADLINK has been working on industrial automation applications for a long time and has built a solid body of knowledge on industrial robot controllers. Secondly, an AI camera is integrated into the start-up’s robotic arm, and AI visual recognition technology is employed to execute tasks. ADLINK’s extensive experience with Edge AI in recent years was therefore considered another plus.

The MVP-6200 itself also incorporated many advanced technical features so this was probably the main reason for its selection. For example, the 12/13-generation Intel Core i9/i7/i5/i3 processor onboard is about 30% faster than the 8/9th generation Intel CPUs generally used in industrial computing today. Memory is also upgraded from DDR4 to DDR5 to boost overall performance by more than 50%, a very considerable improvement. In other words, a robotic arm with MVP-6200 as the controller can pick and move an even larger quantity of goods within the same given period. The attendant increase in order fulfillment rate made for a strong selling point.

At the same time, ADLINK’s proprietary Adaptive Function Module (AFM) design allowed for a high level of customization and expansion in functionality based on client requirements. In this particular case, ADLINK provided the start-up with a function module corresponding to its signal expansion requirement. Integrating the signals directly into the mainboard eliminated unnecessary accessories and wiring that increase the risk of short circuits or oxidization from card contacts, as well as loose or worn wiring due to vibrations in the arm mounting over extended periods. Both maintenance costs and the potential risk of failure are reduced as a result. Thanks to AFM, the end customer can use a single controller to seamlessly connect 2D/3D cameras, tablet teach pendants, conveyor belt sensors, barcode scanners, and other external hardware. Robotic arms and AMRs can then operate smoothly and precisely together to execute the entire shipping process.

ADLINK MVP-6200

Embracing Complex Verification Challenges to Meet Customer Requirements

A strategy of diversification was adopted by ADLINK in industrial computing to better meet market and client requirements. Chou noted that in addition to the flagship MVP-6200 series ADLINK also designed the MVP-5200 series for different application scenarios. The two series share the same technical platform but the MVP-5200 is targeted at specialized applications that do not require PCIe expansion slots. Maintaining a flexible approach to design ensured that the product could be adapted to different production environments and effectively meet the needs of different customers.

The performance of industrial computers is continuing to increase thanks to new generations of CPUs but this also brings even greater challenges in heat dissipation. Effective heat dissipation is of particular importance in the confined environments of factories and warehouses. It is here that the MVP series from ADLINK demonstrates its outstanding innovation. These models are based on a fanless design that delivers high-performance cooling in a small footprint to ensure the machine’s continued stability and reliability under heavy workloads.

The MVP series not only satisfies current industrial automation requirements through its powerful processing performance and exceptional heat dissipation. It is also a demonstration of ADLINK’s leadership in product design and innovation. These models are suitable for applications that require high-performance AI computing. Their compact footprint and outstanding cooling performance provide users with more flexibility during deployment which translates into even greater value for money and a better overall user experience.

“ADLINK was not just chosen for the exceptional performance of the product hardware itself, but its total approach to customer service!” said Chou. Instead of just being a traditional hardware vendor, ADLINK went the extra mile by making an in-depth study of the customer’s requirements and then satisfied those requirements by providing a tailor-made solution. In this case, ADLINK did not just employ AFM design to seamlessly connect all the external devices specified by the client. To ensure the most stable operating environment, ADLINK also introduced Ubuntu Linux compatibility verification services from Canonical, the original manufacturer, to ensure that no matter what OS updates are introduced in the future, all MVP models will remain fully compatible with the OS; the effort is not limited to Ubuntu either. ADLINK will work to maintain stability and compatibility with other platforms such as Debian, Yacto, and Windows as well.

It is worth noting that the new start-up required ADLINK to undergo rigorous whole-machine encryption testing during delivery to maximize supply chain security. The testing ensured every component in the computer was a 100% match for the list of previously verified components. For example, everything on the Flash SSD including the chips, firmware, or even tiny screws had to match or it would fail verification. ADLINK knew that such testing may result in additional hidden costs. Nevertheless, the project will be used with AI applications and industrial automation so this requirement was aligned with ADLINK’s ultimate goal. Every effort was therefore made to meet the client’s expectations by the company philosophy of putting the client first.

It is this in-depth understanding of client requirements and total approach to technical support that gives ADLINK its edge in an extremely competitive market. ADLINK supplies not only high-quality products but is also a one-stop shop for solutions. From hardware to software, and from product configuration to after-market support, a total approach to satisfying customer requirements epitomizes ADLINK’s outstanding performance in customer service.

Learn more about the MVP-6200 or contact ADLINK for more information about products and solutions.