SwRI demonstrates robotics for in-space manufacturing

Innovative technologies are being used for space exploration, especially rovers equipped with advanced software and microprocessors. These capabilities enable them to analyze and navigate unfamiliar terrain with great precision.

US-based Southwest Research Institute (SwRI) has been developing technologies for lunar surface robots and testing cutting-edge robotic capabilities for in-space servicing, assembly, and manufacturing (ISAM) capabilities.

“SwRI is developing solutions to leverage Earth-based industrial robotics with advanced automation and simulation so we can help clients develop new capabilities for the complex conditions of space,” said Meera Towler, a SwRI engineer who leads SwRI’s Space Robotics initiative.

The Space Symposium brings together the best and brightest minds from all over the world to discuss the future of space exploration. Through ISAM, NASA and others envision a space industry with agile vehicles that will deploy parts and materials into space for robotic manufacturing and assembly. An important enabling step for ISAM includes developing Earth- and lunar-based test beds and even research facilities on the surface of the Moon.

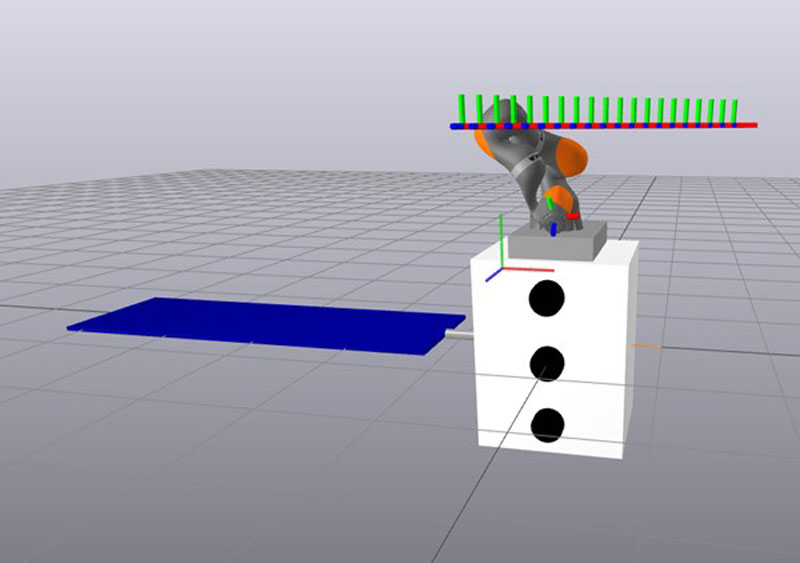

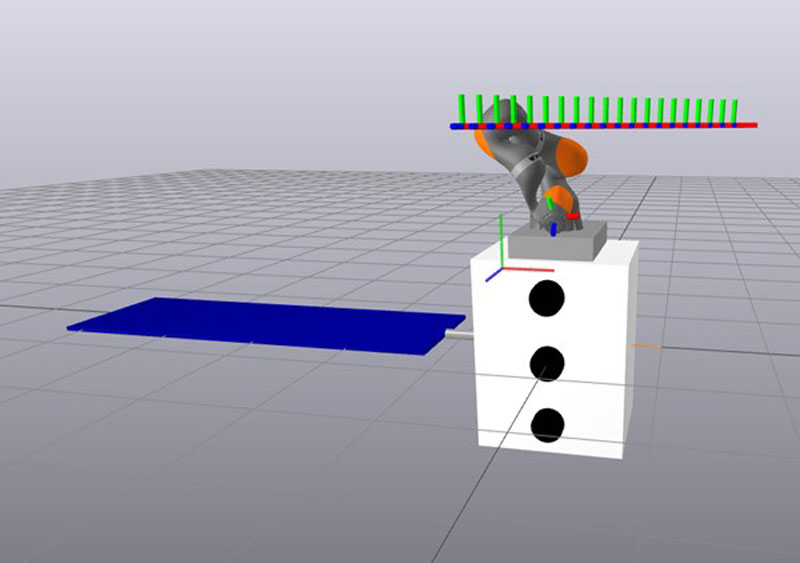

SwRI’s space robotics research focuses on high-fidelity simulation, advanced perception, robotic manipulation in space, and extraterrestrial automated driving. SwRI’s new Space Robotics Center supports this research, including an air-bearing table, a motion capture system, a seven-degree-of-freedom robot arm, test fixtures, and more.

Engineers at SwRI have developed software and modeling tools to help robots plan motion for complex on-orbit conditions. Additionally, the development of efficient low-power vision for lunar rovers or small aerial systems is a crucial step toward making space exploration more accessible and efficient.

“We are excited to share these R&D projects with the space community to help bridge the gap between today’s power-hungry, Earth-based industrial robots and the near-future ISAM ecosystem where advanced automation will help build the next generation of space infrastructure,” said Dr. Steve Dellenback, vice president of SwRI’s Intelligent Systems Division.

SwRI used a physics-based simulation tool to develop a robotics simulation package to address challenges associated with object identification, trajectory tracking, and dynamic motion planning. They will evaluate these simulation models using a robot arm on an air-bearing table in the Space Robotics Center. The company investigated deploying its Ranger localization system on lunar rovers. The ground-facing cameras and automation software have successfully guided a rover across a simulated regolith.

In addition, SwRI is using caves as testbeds to evaluate unmanned aerial systems (UAS) for future space applications. Their new algorithms have successfully used stereo cameras to autonomously guide a small UAS.

SwRI is evaluating the next generation of fast, reliable microprocessors for embedded spaceflight systems. Some space-ready FPGAs outperformed conventional processors, and an Advanced RISC Machines (ARM) processor outperformed a legacy space processor, using a fraction of the energy.