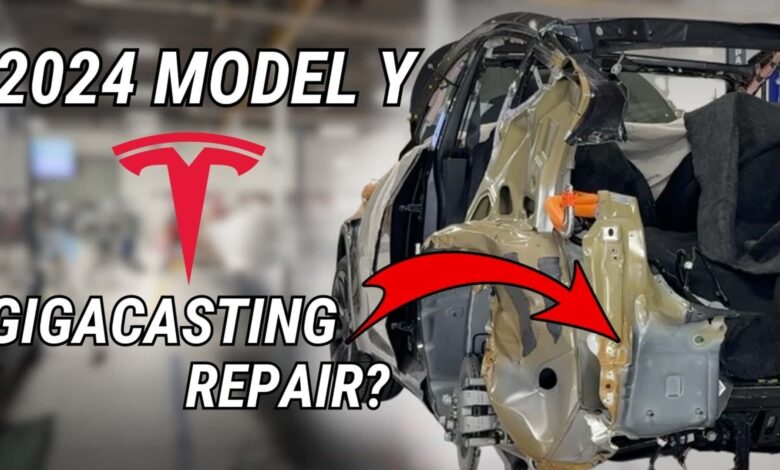

Tesla Model Y Gigacast Repairs Have Improved Greatly

A few years ago, any collision damage to a gigacast element would have meant replacing the entire piece. That’s no longer the case.

A few years ago, Tesla became an early mover in the use of a new vehicle manufacturing technique called gigacasting. Using a large casting machine, automakers could now assemble a vehicle’s underbody using only a handful of segments, greatly reducing the hundreds of individual components in a traditional car. Because of this, Tesla was able to drastically lower costs and improve production efficiency of the Model Y.

However, people have had understandable concerns about what happens when a Model Y is in a collision. How easy is it to find replacement parts? Are repairs more expensive than traditional manufacturing methods? Is repair work even possible or is your car more likely to be totaled?

Is Tesla Abandoning Gigacast Manufacturing? Probably Not.

Last month, Reuters reported that Tesla was dropping development of previously reported “gigacasting 2.0” techniques that were originally intended for future small vehicle platforms.

While the underbodies of the Model Y and Cybertruck are assembled using three large gigacast pieces, this next-gen version would instead be stamped out with a single piece for the entire underbody. It is too soon to say whether this new method eventually comes to fruition. However, there has been no reports of Tesla walking back their current implementation.

To answer some of these questions, John from the Evolve EV Specialists YouTube channel takes us through the inspection of a Model Y that was recently involved in a collision. He says the process of repair work on these vehicles has become much better recently. “Early on, it was sort of an all-or-nothing thing. We had to replace them.” Explains John. “But since then, there are lots of repair methods that have been developed.”

John points out a line running through the rear frame rail of the vehicle. If damage had occurred here, the portion could have been severed and replaced. “We have the option to literally cut this off and attach a new piece of cast aluminum to this spot.” The new piece would be attached using rivets, structural adhesives and a backing plate.

When inspecting a Model Y for damage, they’re looking specifically for cracks in the cast aluminum. He says that after a severe collision, most vehicles will see some movement in the multiple structural components that make up the underbody. However in a Tesla, while the Gigacast pieces do have some flexibility and the possibility to bend, in most cases they shatter.

Thankfully for this vehicle owner, there appear to be neither cracks nor bends in the rear frame rail. “What’s interesting is as hard as this thing was hit? There is no damage to the gigacasting. Incredibly well designed and an incredibly strong vehicle for a hit that hard.”

Still, repair cost and complexity can vary greatly depending on where that damage occurs. For many segments of a gigacast piece, small 50mm cracks can simply be welded up. Other areas can be welded up to 30mm as long as a backing plate is put behind it for support. However, there are several problem areas where a shop will need to consult with Tesla directly to assess the damage and confirm that a repair is possible. In some of these cases, the entire piece may need to be replaced.

So, while repair work can still be difficult, the process has improved significantly over the years. “As these develop, more and more repair options are becoming available. So the original thinking that gigacasting damage means total loss? It’s actually not real. We have certainly replaced entire giga castings, but we’ve also certainly repaired them as well.”

Was your early build Model Y totaled in a major collision due to a lack of affordable repair options? Let us know your experiences in the comments below.

Gallery: 2021 Tesla Model Y

27 Photos

Read more