Toshiba Clip | Toshiba’s Hybrid Electric Vehicle Motors: Driving Ford and the Industry Forward

Did you know that one of today’s hottest new automotive technologies isn’t as brand new as it seems? It’s true. According to the United States Department of Energy (DOE), hybrid electric vehicles (HEV) date back to 1901*1, seven years before Ford unveiled its first Model T.

Now, more than a century later, HEVs are more popular than ever. They’ve evolved to become go-to choices for consumers looking to improve their own carbon footprints while holding onto the convenience gas-powered vehicles provide. In the United States, HEV sales soared 53% in 2023*2, while electric vehicle sales also rose by more than 40%*3, according to the DOE and the International Energy Agency.

Toshiba is at the forefront of the HEV revolution, having manufactured HEV systems since the early 1990s. Today, Toshiba’s U.S. HEV division actively collaborates on research and development with the parent plant in Japan, accelerating innovation and introducing new technologies that bring value to the automotive industry. Through the development and widespread adoption of motors for electrified vehicles, Toshiba is providing sustainable mobility solutions to people and contributing to a more sustainable future.

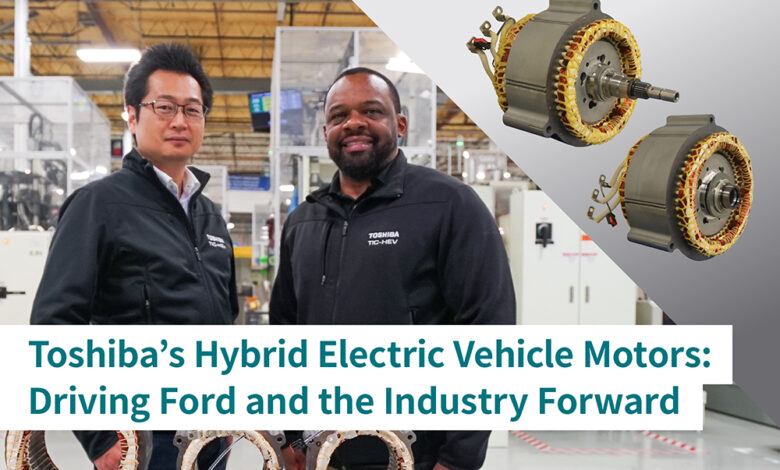

Collaboration with Ford and Toshiba’s Role

Toshiba’s work with Ford Motor Company started in 1999 with the co-development of a dual-motor HEV system that is specific and exclusive to Ford’s transmission. The innovative system launched Ford’s push into the HEV market, establishing the company as the second-largest supplier behind Toyota. Ford first deployed Toshiba’s HEV motor in its 2004 Escape-Hybrid, then installed it in the C-Max, Fusion and Lincoln MKZ.

Toshiba’s dual-motor HEV system touts both a conventional internal combustion engine, powered by gasoline, and an electric propulsion system. This design makes these vehicles suitable for drivers in areas with underdeveloped charging infrastructure while still contributing to the reduction of automotive exhaust emissions.

Toshiba began as a Tier 2 manufacturer for Ford in 2004, subcontracting components to direct Tier 1 suppliers. Ford elevated Toshiba to Tier 1 status in 2009. The partnership with Ford spurred Toshiba to shift its HEV motor development and engineering processes from Japan to the U.S. offices in Wixom, Mich., 30 miles west of Detroit. Three years later, Toshiba opened a manufacturing plant in Houston. This allows for domestic development and shipping of parts and products, resulting in fully American-made motors for Ford HEVs.

“‘Made in the USA’ still builds American consumer confidence,” said Achilles Harris, HEV Plant Manager in Houston, who has more than 20 years of experience in the automotive industry. “Consumers are happier buying products that have that tag as part of their make-up. Not to mention, when we build locally, we can resolve quality control issues in a timely manner.”

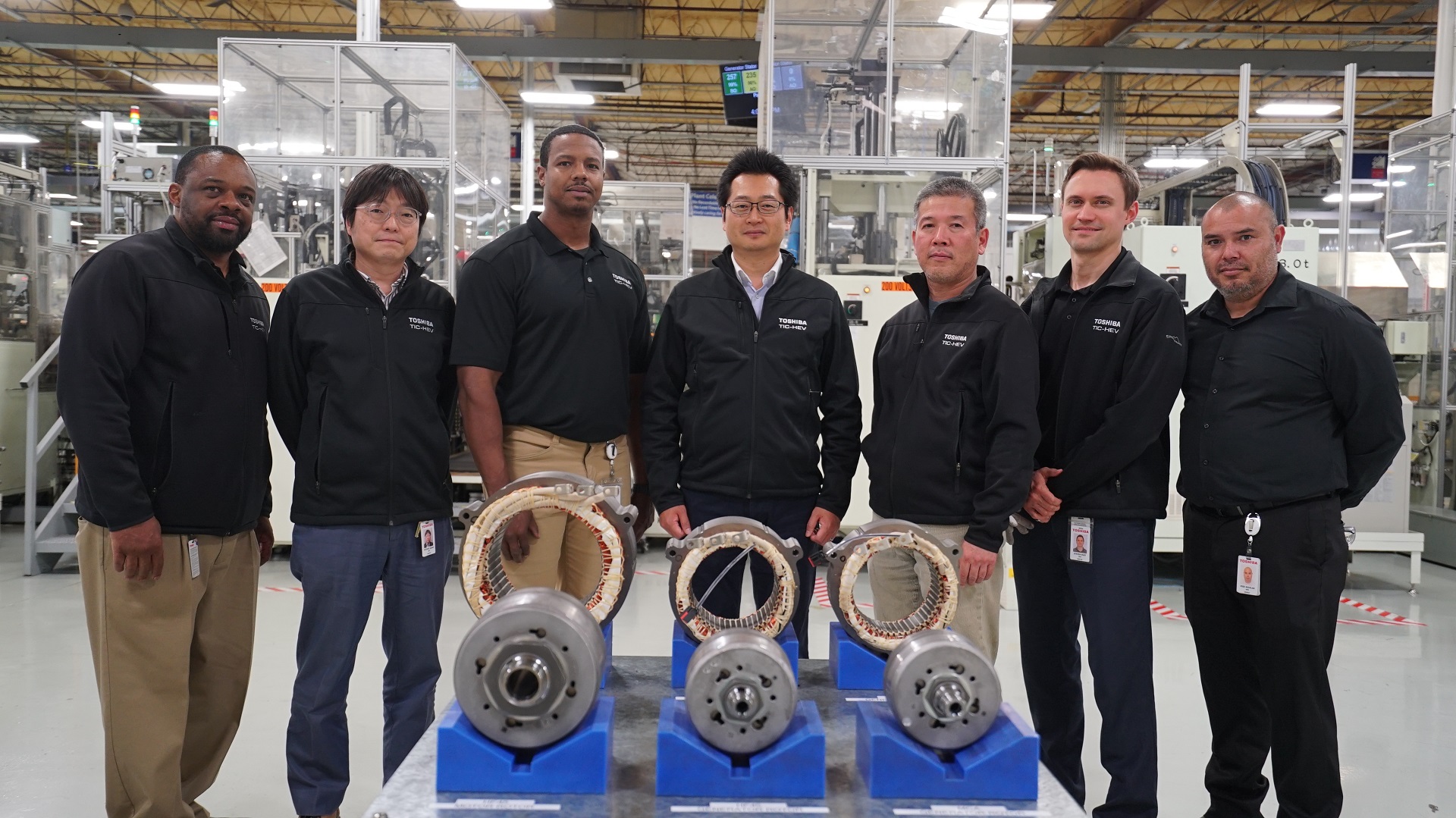

Toshiba’s HEV Plant in Houston

Driving Sustainable Automotive Innovation

John Hayden, a 30-year auto industry veteran who serves as Senior Sales Manager of the Automotive Systems HEV Division at Toshiba’s Wixom office, has been working directly with automakers for the past 15 years. Hayden said he particularly enjoys collaborating with his team and customers to solve everyday problems and develop strategies to improve the performance of individual components in the future.

“We’ve built a strong working relationship and a successful collaboration with Ford across our practices in Michigan, Houston, and Japan,” he said.

As the automotive sector continues to expand its lineup of HEVs, Toshiba is stepping up production of its high-performance motors, supplying more HEV motors to meet increasing demand. This enables automakers to offer a diverse range of hybrid and fully electric vehicle options, aiding consumers in smoothly transitioning to more sustainable driving options. Such efforts contribute to the growing consumer desire for environmentally friendly vehicles and help meet fuel efficiency regulations.

“Our collaboration with leading automakers successfully offers consumers sustainable vehicle options,” said Nobunori Mashimura, VP & General Manager, HEV at Toshiba’s Houston plant. “The ability of these companies to expand their HEV offerings with Toshiba’s high-quality and high-performance motors keeps them competitive among other hybrid and electric vehicle offerings.”

Mashimura has been with Toshiba’s automotive systems division for more than 15 years, beginning as a sales account manager and working his way up in the company. In his role, Mashimura enjoys collaborating with teams to lead the organization and achieve its mission. He takes pride in his daily work, knowing that he contributes to the advancement and improvement of technology.

Stator production line. All production stations are operated by certified operators.

Improving Energy Efficiency and Contributing to Carbon Neutrality

Ford is pleased with the reliability, durability, and quality of Toshiba’s motors, due in part to the efficient manufacturing practices at the Houston plant. In fact, Toshiba won the Ford Q1 Preferred Quality Status award in its second year of production, in January 2014, further solidifying itself as a trusted partner to Ford.

“Toshiba’s HEV motors positively impact energy usage and clean air,” Hayden explained. “Just take the hybrid Ford Escape as an example. It can get up to 42 miles to the gallon, resulting in reduced carbon emissions and reduced gasoline use. It’s a win-win for consumers who want to make more sustainable choices while decreasing their time and money at the pump.”

According to Consumer Reports, using less gas saves HEV owners a bundle of money—as much as $4,000*4 over the life of the vehicle compared to a conventional gas-powered vehicle. Not only that: HEV owners are being spared the inconvenience of spending hours every week waiting at a public plug-in recharging station or the costs (thousands of dollars) of having to install an at-home electric charging station.

“Hybrid provides a superior alternative when it comes to time saved for vehicle recharging compared to EVs,” HEV plant manager Harris said. “Hybrid vehicles also offer increased fuel efficiency without the range limitations of EVs, which is another perk for consumers wanting to contribute to a greener future.”

HEV Management Team of Toshiba International Corporation (TIC): Achilles Harris, Plant Manager (leftmost), Nobunori Mashimura (center)

Paving the Way for Electrified Vehicles

Looking ahead, demand for HEV sales is expected to grow by a compound annual growth rate of 7.3% between 2023 and 2030*5, according to Fortune Business Insights. However, HEVs are just one option consumers have as they seek to improve fuel efficiency. They can decide to purchase a plug-in hybrid electric vehicle (PHEV) or a fully electric vehicle. In the future, additional options may emerge based on technological advancements, changes in environmental regulations, and influx in consumer trends. While development of next-generation battery technology and improvements in charging infrastructure are expected to drive EV adoption, higher vehicle prices and delays in infrastructure development may have slowed the initial projected growth of battery electric vehicles (BEVs).

Knowing that consumers are becoming more carbon conscious and more interested in electrification, Toshiba’s motor technology can support full electric vehicle, also manufacturing batteries for fully electric vehicles.

“All vehicles are trending towards electrification,” said Mashimura. “Toshiba has been manufacturing automotive motors since the early 1990s. With decades of expertise in this field, we are well-equipped to navigate the competitive landscape of HEV and EV technologies.”

Although HEVs are positioned as vehicles meant to facilitate the transition to EVs, HEV demand cannot be ignored. Based on consumers’ location and transportation needs, HEVs will continue to be an essential choice for those seeking a sustainable transportation option, contributing to environmental well-being without relying on electric charging infrastructure.

As consumers transition from gas-powered vehicles to HEVs, and eventually to fully electric models, Toshiba will continue to support this shift with our advanced motor technologies. We are fully prepared for the future of electrified vehicles.

*1 https://www.energy.gov/articles/history-electric-car

*2 https://www.energy.gov/eere/vehicles/articles/fotw-1343-may-20-2024-hybrid-electric-vehicle-sales-united-states-grew-53

*3 https://www.iea.org/reports/global-ev-outlook-2024/trends-in-electric-cars

*4 https://advocacy.consumerreports.org/wp-content/uploads/2023/10/CR-Fact-Sheet-Hybrid-Cost-Savings.pdf

*5 https://www.globenewswire.com/en/news-release/2023/07/31/2714909/0/en/Hybrid-Vehicle-Market-Size-Worth-USD-443-91-Billion-Globally-by-2030-at-a-CAGR-of-7-3.htm

![]()