Transforming Indian industry: Robotics and automation lead the charge

Indian manufacturing stands at an inflection point today. We are well-positioned to take advantage of the realignment in global value chains and position ourselves as a meaningful alternative to our eastern neighbour. But we must move fast to achieve our ambitious goals.

GoI’s stated objective is to increase the share of manufacturing to 25% of GDP, up from the current ~15%, as part of Make in India. To achieve this, the Economic Survey of India 2019–20 paints a compelling narrative of an export-led strategy focused on product assembly / discrete manufacturing.

While this is a real and significant opportunity, it would require focusing effort towards industries (within the product assembly space) where large economies of scale and vertical integration can be achieved at a war footing.

Notably, the current industrial policy and fiscal incentives have been architected to achieve exactly this – 8 out of 14 sectors covered under the PLI constitute high-growth product assembly.

These sectors have already begun to show promise. Auto component exports exceeded the 30% figure (as a percentage of industry revenue) in FY24. Similarly, we witnessed a 22.24% surge in electronics exports in FY24, breaching the $20 billion milestone three quarters into the year.

Green shoots of progress, evidenced by growth in exports, credit and tax payments for both SMEs and large enterprises in these sectors underscore potential. But the key lies in increasing ecosystem competitiveness to create a viable manufacturing hub. We have already seen some success in sectors such as automotive, where Indian cos. have gone on to become global giants.

Building and Increasing Competitiveness

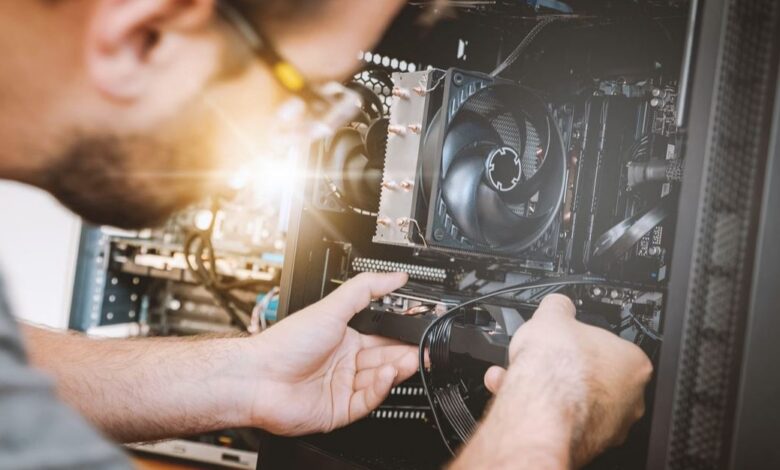

In order to achieve our economic goals while helping Indian cos. (i) compete in global markets and (ii) support higher wages / living standards for workers, we must work on increasing competitiveness. This will depend on improving long-term productivity (not low wages or currency arbitrage), majorly led by digital transformation and robotic automation.

Notably, product assembly based industries worldwide (especially automotive and electronics), have been at the leading edge of embracing robotic automation to streamline operations, enhance quality, and boost productivity. This trend is beginning to repeat itself in India.

The World Robotics Report 2022 highlights the correlation between presence of large manufacturing hubs and investment in robotics. China, Japan, US, South Korea and Germany account for 78% of global robot installations. India showed up in the 10th spot on the list, underscoring its nascent journey. With considerable whitespace waiting to be filled, the potential for growth of robotics in India is immense.

Robotics for the Indian market

While Indian manufacturing is well on its way to make its mark globally, solutions that work for the global market are often value-prohibitive for India Inc. As India navigates the complexities of manufacturing automation and robotics, the fundamental challenge of ROI remains. There is a sweet spot between full custom, and general autonomy, that is waiting to be built at the right price for Indian industrial use cases.

Finally, the vision to push manufacturing to 25% of GDP cannot be solely focused on financial metrics. The manufacturing sector’s success must extend beyond profitability to include enhancement of productivity, higher quality goods and creation of high skill jobs.

These are all benefits that will accrue as we build indigenous solutions for digital transformation and robotic automation specific to our use cases and ecosystem.