Two-Finger Robotic Hand for Precise Object Manipulation

In a recent article published in the journal Sensors, researchers introduced a two-finger haptic robotic hand for manipulating objects with varying stiffness and shapes without causing damage or slippage. They employed force sensors and servomotor currents to categorize objects based on their stiffness and apply appropriate force for grasping and lifting. A novel impedance control algorithm that adjusts the stiffness and damping properties of the robotic fingers based on the object characteristics was also designed in this study.

Background

Haptic technology refers to the technology that uses touch and tactile sensations to enable interactions between humans and machines or between machines and objects. Haptic hands and grippers are devices that mimic the capabilities of the human hand for grasping and manipulating objects. These devices are especially useful in fields such as minimally invasive surgery, prosthetic limbs, and industrial automation and manufacturing, where they enhance the accuracy, tactile feedback, functionality, and flexibility of robotic systems.

However, designing and controlling haptic hands and grippers that can handle diverse objects with unknown properties and dynamic interactions pose several challenges, especially when dealing with unknown objects that have diverse sizes, shapes, and stiffness levels. Various control strategies, such as tactile, visual, and force feedback, have been proposed and implemented to address these challenges and to improve the performance of haptic hands and grippers. However, most of these strategies have limitations in terms of accuracy, complexity, dexterity, or adaptability.

About the Research

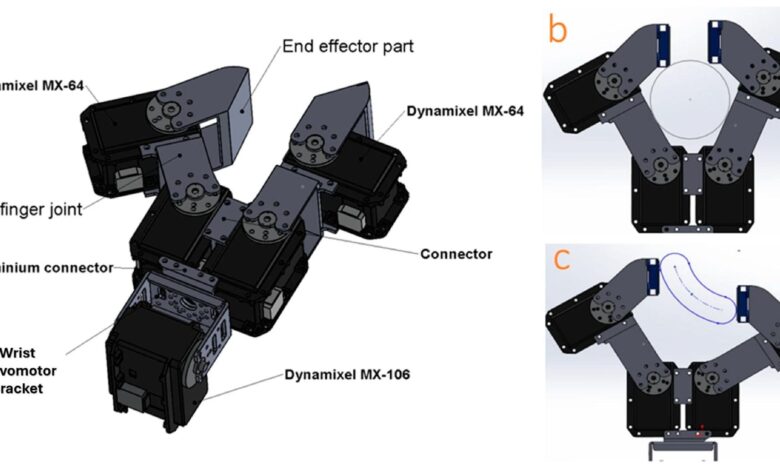

In this paper, the authors presented the design and evaluation of a unique two-finger robotic hand for grasping unfamiliar objects. The two-finger design, inspired by the thumb and index finger, offers essential functionalities for object manipulation. Each finger has two joints controlled by servomotors and a force-sensitive resistor (FSR) sensor at the tip for touch sensitivity. The wrist joint allows for flexion and extension.

The study introduced a novel impedance control algorithm that dynamically adjusts the stiffness and damping properties of robotic fingers based on the object’s characteristics. Impedance control, a versatile control strategy, enables the robot to switch between rigid and flexible states depending on the task and environmental conditions. To simulate impedance control, a mass-spring-damper system was employed, utilizing current values measured at each servomotor to estimate external forces acting on the hand.

The impedance control algorithm comprised three phases: close, load, and load adjustment. Initially, in the close phase, the fingers approached the object until contact was detected by the FSR sensors.

Subsequently, in the load phase, the fingers applied a slight additional force to the object and measured the current difference between the close and load phases to categorize the object’s stiffness. Finally, in the load adjustment phase, the fingers adjusted their force and position based on the stiffness category and inverse kinematic equations to achieve a secure and reliable grasp.

Additionally, the authors evaluated the performance of the robotic hand using six objects sourced from the Yale-CMU-Berkeley (YCB) object set, commonly employed for benchmarking robotic manipulation capabilities. These objects comprised a sponge ball, an empty soda can, an apple, a glass cup, a plastic cup, and a small milk packet, varying in size, shape, and stiffness levels from soft to stiff.

Each object underwent ten grasping experiments, during which the study recorded current values and servomotor angles at each stage of the grasping process. The grasping process encompassed five key steps: approaching the object, establishing contact, lifting, setting down, and releasing the object.

Research Findings

The results demonstrated the robotic hand’s adeptness in successfully grasping and lifting all six objects across 60 experiments without any instances of damage or slippage. It effectively categorized object stiffness by analyzing measured current difference values at the close and load phases. This allowed for tailored application of force and position corresponding to each object’s stiffness category and FSR values obtained from manual experiments. Moreover, the close alignment between servomotor angles during load adjustment and manual experiment angles underscored the hand’s ability to maintain secure and reliable gripping configurations.

For example, the hand-applied minimal force utilized a wider grip for soft and deformable objects like the sponge, whereas it exerted greater force and employed a narrower grip for hard and rigid items like the metal clamp. Additionally, it adeptly managed objects with variable stiffness, such as the banana, by adapting its grip accordingly.

Comparative analysis highlighted the proposed hand’s superiority over the baseline hand in terms of success rate, grasp force, and grasp position metrics. The baseline hand exhibited shortcomings, including failure to lift certain objects due to slippage or instability, like the tomato and mustard bottle, and the application of excessive force or improper positioning for objects like the sponge and metal clamp, potentially resulting in damage or inefficiency.

The proposed robotic hand holds promise for diverse applications requiring precise object manipulation and tactile feedback. It could enhance surgical precision and minimize tissue damage in minimally invasive procedures, enhance functionality and tactile sensation in prosthetic limbs, and optimize efficiency, safety, and flexibility in industrial automation and manufacturing processes.

Conclusion

In conclusion, the novel robotic hand effectively manipulated objects of varying stiffness levels using haptic feedback and impedance control. It demonstrated precise grasping and lifting abilities with objects from the YCB set, highlighting simplicity, cost-effectiveness, and efficacy. The researchers suggest further enhancements by integrating more sensors, actuators, and degrees of freedom and extending the control algorithm for handling complex scenarios like object slippage, deformation, or rotation.

Journal Reference

Mohammadi, V.; Shahbad, R.; Hosseini, M.; Gholampour, M.H.; Shiry Ghidary, S.; Najafi, F.; Behboodi, A. Development of a Two-Finger Haptic Robotic Hand with Novel Stiffness Detection and Impedance Control. Sensors 2024, 24, 2585. https://doi.org/10.3390/s24082585, https://www.mdpi.com/1424-8220/24/8/2585.