Understanding the Role of IoT in Robotics for Transforming Industries

The integration of IoT in robotics is not just about connecting devices; it’s about creating intelligent systems that can adapt and learn from their environment. These interconnected robotic softwares can optimize processes, predict maintenance needs, and enhance decision-making capabilities by harnessing the power of real-time data exchange and advanced AI algorithms.

From smart factories where robots collaborate with humans to optimize production lines, to autonomous vehicles navigating city streets, the possibilities are endless. As IoRT continues to advance, it promises to revolutionize industries, unlocking new levels of efficiency, safety, and innovation in the ever-evolving automation landscape.

In this blog, we will study how IoT is used in robotics, its basic and advanced features, its applications, and how IoT in robotics impacts various sectors. However, we will first begin by analyzing the Internet of Robotic Things market. Let’s take a quick walkthrough.

IoT in Robotics Market Overview

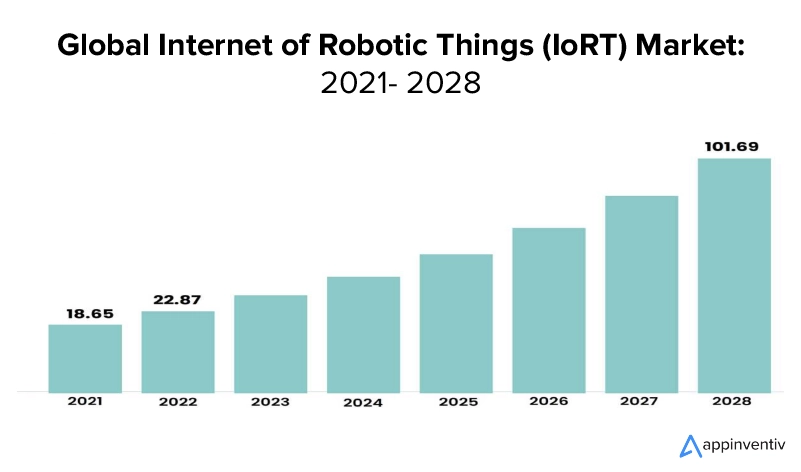

As per a report by Startview Research, the Internet of Robotic Things (IoRT) market is expected to reach a valuation of $101.69 billion by 2028, developing at a CAGR of 27.4% between 2021 and 2028. This growth is driven by the integration of IoT, which makes data sharing and networking easier. The surging adoption of IoT in industrial robotics is further propelled by the escalating industry demands for automation across various sectors.

IoRT is pivotal in enhancing control and monitoring capabilities, crucial for efficient remote management practices spanning multiple industries. Furthermore, IoRT devices are becoming more intelligent and adaptive due to sensor developments. Combining robotic software with IoT generally satisfies growing industry demands, promoting the growth of IoRT into industries such as manufacturing, healthcare, logistics, and more.

As businesses increasingly embrace IoRT solutions, they are poised to unlock unprecedented operational efficiency, agility, and innovation levels in the evolving automation landscape.

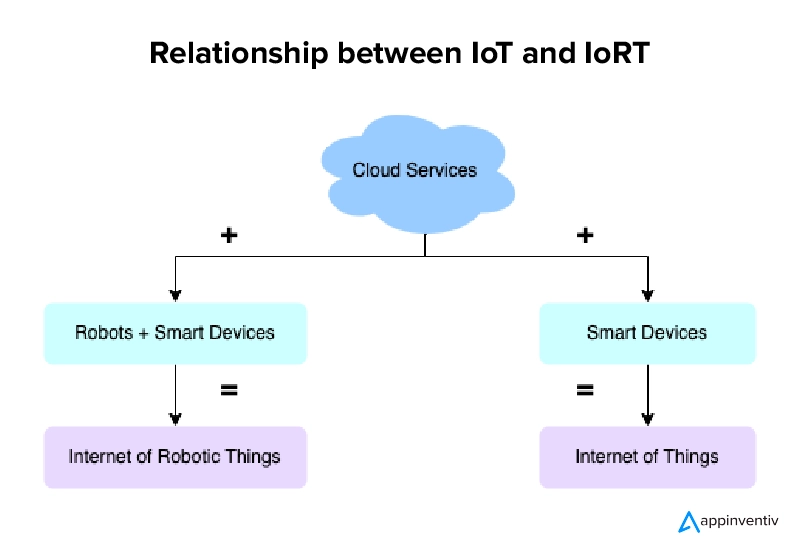

How is IoT Used in Robotics?

IoT enhances robotics software by providing a networked infrastructure for communication and data exchange. Robotic sensors gather real-time data on user interactions, performance indicators, and environmental factors. This data is then transmitted over the internet to centralized servers or cloud platforms, where it is analyzed to derive actionable insights.

These insights empower robots to adjust their behavior in real-time, optimize operations, and autonomously make informed decisions. Additionally, IoT facilitates remote monitoring and control of robotic systems, enabling operators to manage fleets of robots from anywhere worldwide efficiently. Overall, IoT integration revolutionizes automation across industries, enhancing robotics with greater capability, intelligence, and connectivity.

Also Read: The Handbook You Need to Understand Robotic Process Automation

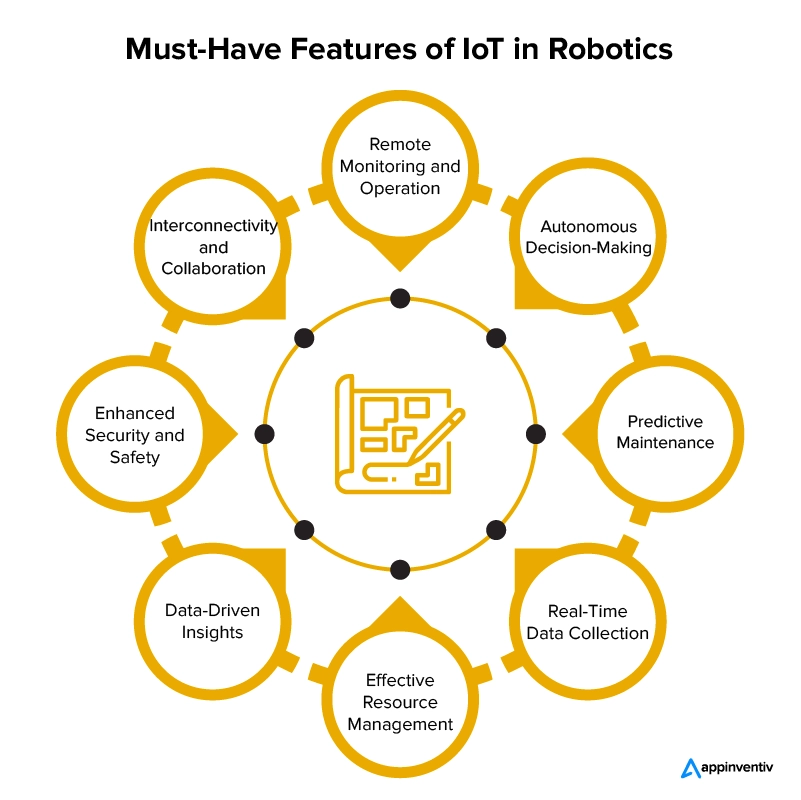

Key Features of IoT in Robotics

Integrating IoT technology in the robotics software enhances communication, collaboration, and adaptability in changing environments more effectively, improving performance and productivity. Let’s check out the top features of the Internet of Robotic Things software.

Remote Monitoring and Operation

With IoRT connectivity, operators can remotely monitor and control robotic systems from anywhere with internet access, enabling efficient management and supervision.

Autonomous Decision-Making

Robotics software effectively utilizes AI algorithms and IoT data to enable autonomous decision-making based on real-time information.

Predictive Maintenance

By utilizing the predictive maintenance feature, IoRT software provides valuable insights that facilitate timely maintenance interventions, ensuring equipment operates at peak efficiency while avoiding costly disruptions.

Real-Time Data Collection

The IoRT software gathers data in real-time from various sensors and devices, giving users insights into their surroundings, efficiency, and performance.

Effective Resource Management

The Internet of Things in robotics enhances resource efficiency by offering insights into energy usage, material usage, and workflow effectiveness. This results in financial savings and environmental advantages.

Data-Driven Insights

IoRT makes it easier to gather and analyze the vast amounts of data produced by robotic systems, giving businesses useful information for decision-making, process optimization, and ongoing development.

Enhanced Security and Safety

Implementing robust safety procedures and security measures in IoRT software solution ensures secure operations and safeguards against cyberattacks.

Interconnectivity and Collaboration

IoRT promotes interoperability and coordination in complex environments by enabling software to communicate and work with other IoT-enabled objects and systems.

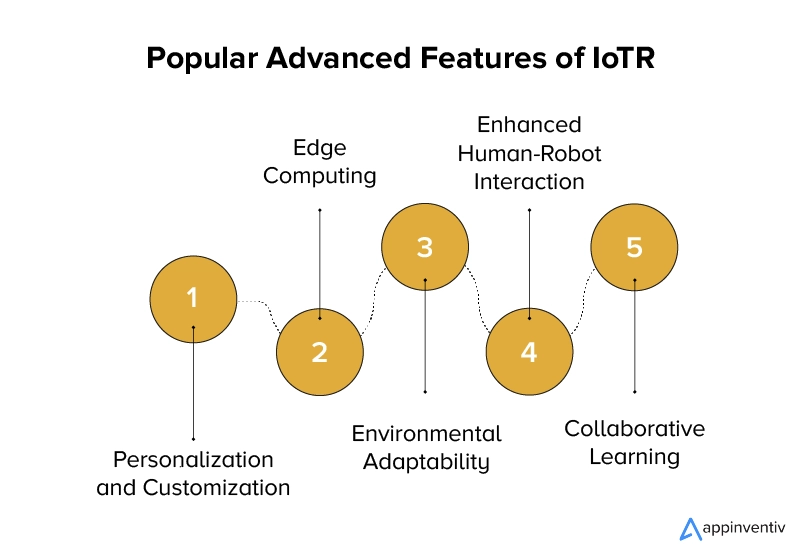

Exploring the Advanced Features of IoTR

Advanced features of IoRT enable systems to anticipate and prevent failures, continuously improve performance through data-driven insights, and foster more intuitive and collaborative relationships between humans and robots. Let’s examine those.

Personalization and Customization

IoT integration enables robotics software to tailor actions and tasks to individual needs, considering user preferences and environmental factors for enhanced user experiences.

Edge Computing

The Internet of Robotic Things can process data locally and in real-time by utilizing edge computing capabilities. This lowers latency and dependency on cloud infrastructure and allows for faster response times for important activities.

Environmental Adaptability

Using IoT sensors, robotics software can adjust to varying environmental factors like humidity, temperature, and illumination, resulting in optimal performance in various operational scenarios.

Enhanced Human-Robot Interaction

IoRT improves human-robot interaction by allowing software systems to understand and react to human speech, gestures, and commands. It also promotes more intuitive and natural communication.

Collaborative Learning

IoT in robotics facilitates collaborative learning among robotic systems by enabling them to share data, experiences, and insights, leading to collective improvements in performance and capabilities over time.

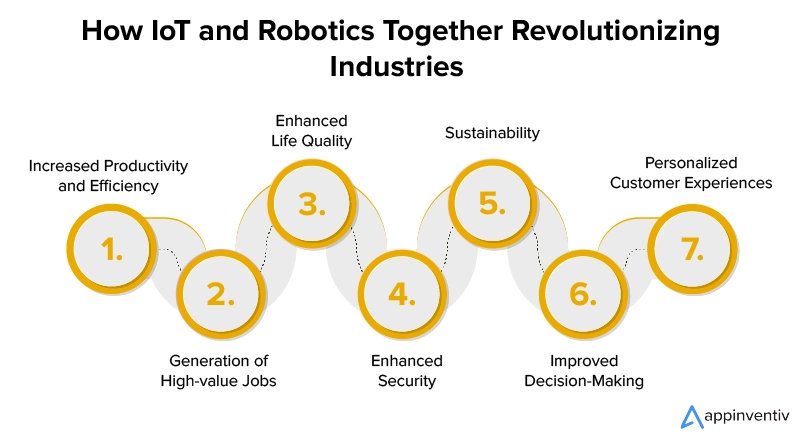

How IoT and Robotics Are Together Transforming Industries and Workforce

Integrating IoT and robotics profoundly transforms industries and the workforce, bringing in a new era of efficiency, innovation, and opportunity. Here are some of the positive impacts of IoT and robotics in various industries:

Increased Productivity and Efficiency

Robotics systems with IoT capabilities automate labor-intensive and repetitive operations, resulting in notable increases in productivity and efficiency. This translates into shorter lead times, lower error rates, and improved supply chains in sectors like manufacturing, all of which boost overall company expansion and competitiveness.

Additionally, this enhanced productivity and efficiency enable businesses to reallocate human resources to more strategic, innovative, and value-added activities, building a more engaging and fulfilling work environment. It also paves the way for businesses to achieve sustainable growth by optimizing resource utilization and minimizing waste, further reinforcing their competitive edge in a rapidly evolving marketplace.

Generation of High-value Jobs

Automation can replace certain manual tasks but also increase demand for high-paying positions in cybersecurity, artificial intelligence, robotics engineering, and data analytics. This change encourages a more trained workforce, which promotes innovation and economic expansion.

Furthermore, this shift to high-value positions emphasizes the significance of ongoing education and workforce adaptability, pushing professionals to pick up new skills in line with technology breakthroughs. Additionally, it encourages industry and academic partners to work together to create curricula that adapt to the changing demands of the labor market, ensuring a talent pool ready to fuel future innovations.

Enhanced Life Quality

Through telemedicine, robot-assisted surgery, and sophisticated diagnostic tools, IoT and robotics in healthcare enhance patient care. Robotic devices can provide much-needed independence and support for the elderly and disabled. Beyond healthcare, the Internet of Things and robotics improve people’s quality of life by automating daily duties.

For example, personal assistants and intelligent home security and comfort systems free up time for people to spend with their families. These innovations also enable remote monitoring and assistance, offering peace of mind to families with elderly members or individuals living alone, ensuring their safety and well-being even from a distance.

Enhanced Security

Robots can take over risky jobs in hazardous workplaces like chemical factories or construction sites, reducing workplace accidents and improving safety. IoRT sensors can also continuously monitor the surrounding environment to protect employees better. Additionally, incorporating wearable IoT devices adds a layer of personal safety by enabling employees to monitor their health in real-time and identify indicators of exhaustion, fatigue, or exposure to hazardous materials.

This proactive approach emphasizes the importance of each person’s health and safety and not only stops incidents before they happen but also fosters a workplace safety and well-being culture.

Sustainability

IoT in robotics optimizes energy use and reduces waste, promoting sustainability. Precision farming techniques, for instance, can reduce the amount of water, fertilizer, and pesticide used in agriculture, resulting in more environmentally friendly farming methods.

In addition to enhancing agriculture, these technologies allow smart cities to lower carbon emissions and manage waste better by implementing effective public transportation and energy-efficient construction. Integrating robotics and IoT into urban infrastructure improves inhabitants’ quality of life and leads to a more sustainable and ecologically conscious future.

Improved Decision-Making

IoT in robotic systems can streamline operations and foster innovation in data analysis and decision-making. IoT devices collect massive volumes of data; therefore, robotic systems with sensors and AI capabilities are necessary for effective data collection in various contexts.

By automatically analyzing machinery and identifying potential flaws early on, the IoRT software greatly aids predictive maintenance initiatives by reducing downtime and increasing asset lifespan. Moreover, these robotic systems optimize workflows and boost operational efficiency by streamlining procedures based on insights from IoT data analysis.

Personalized Customer Experiences

Owing to IoRT, businesses can better understand and anticipate customer needs, resulting in more engaging and tailored customer experiences. IoRT, for instance, can track retail goods in real-time, and robots can provide individualized shopping assistance.

Moreover, this technology makes it possible to create dynamic user profiles, allowing businesses to offer highly personalized marketing, goods, and services that appeal to certain tastes and habits. This degree of personalization creates a closer connection between the company and its customers by making them feel valued, thus increasing consumer satisfaction and loyalty.

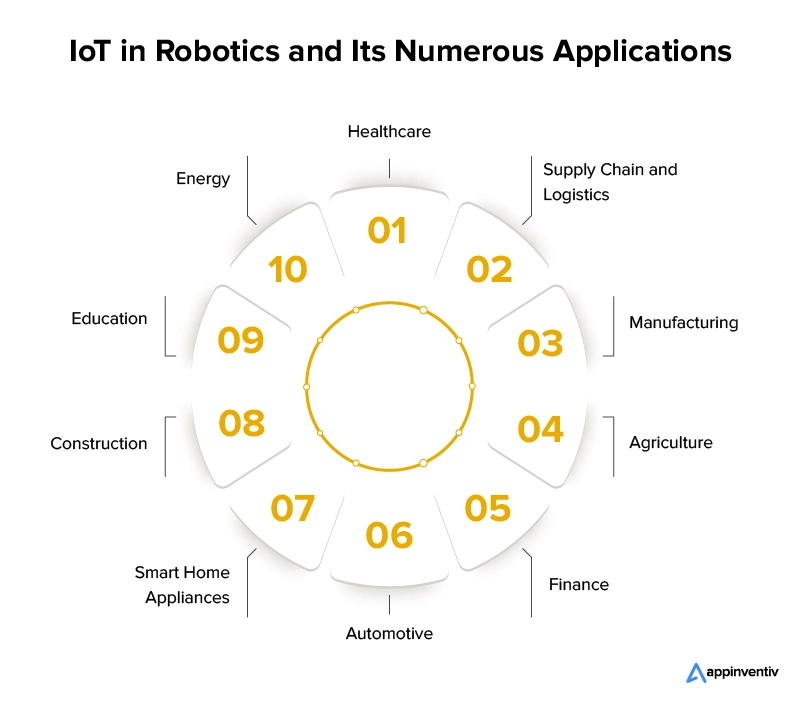

Industry Applications of IoT in Robotics

There are numerous applications of IoT in robotics, ranging from optimizing production processes and enhancing efficiency to facilitating remote monitoring and assistance. Let’s have a look at some of those.

Healthcare

IoT and robotics are essential for assisting patient care and enhancing operational effectiveness in healthcare environments. These robots help with several activities, such as drug distribution, patient monitoring, and rehabilitation exercises.

By utilizing IoT technology in healthcare, medical organizations can improve patient outcomes and safety by ensuring precise and timely medication administration, therapy sessions, and data collection. IoT-enabled robotic systems also lessen the workload for medical personnel, freeing them to concentrate on more intricate and important facets of patient care.

For instance, Johnson & Johnson utilizes robotics in healthcare with their robotic-assisted surgical systems, such as the da Vinci Surgical System. This advanced technology allows for minimally invasive procedures, reducing patient recovery times and improving surgical outcomes.

Also Read: IoMT in Healthcare: A Modern Approach to Patient Care

Supply Chain and Logistics

Our IoT-powered robotics software automates logistics processes such as picking, sorting, and replenishment, transforming inventory management. These systems efficiently navigate warehouse environments using IoT sensors and data analytics, cutting order fulfillment times and labor costs.

IoT technology’s real-time tracking and monitoring features help warehouses maintain ideal inventory levels, improving customer satisfaction and operational efficiency. Amazon, for example, extensively employs robots in its warehouses through its subsidiary , Amazon Robotics. Automating processes like ordering and sorting, these robots, including the Amazon Picking System, allow for quicker order fulfillment and effective inventory control.

Also Read: IoT in Supply Chain and Logistics – Benefits, Use Cases & Challenges

Manufacturing

IoT-enabled robotic systems are key in streamlining assembling, welding, and packing procedures in contemporary manufacturing processes. The underlying software in these robotic systems use IoT technology to gather and analyze data in real-time, optimizing workflow efficiency and enabling preemptive maintenance to avoid expensive downtime.

Integrating robotics with IoT in manufacturing improves operational performance by increasing productivity and guaranteeing constant quality control across the production line. For instance, General Electric (GE) uses IoT-enabled robots in its manufacturing processes. Integrating IoT sensors and analytics, its Brilliant Factory program optimizes production efficiency and quality control, enhancing operational performance throughout its manufacturing sites.

Agriculture

IoT-powered robotics software in agriculture enhances precision farming methods, which maximize resource efficiency and crop management. These systems monitor environmental variables, crop health, and soil conditions, giving farmers important information they may use to make informed decisions.

IoT-enabled robots increase production and efficiency with minimal negative environmental impact by autonomously planting, applying pesticides, and harvesting. Utilizing IoRT in agriculture yields numerous benefits, including increased crop yields, reduced input costs, and the implementation of sustainable farming practices for long-term viability. Deere & Company, a globally reputed agricultural machinery manufacturer, incorporates IoT-enabled robotic softwares into their equipment. Utilizing IoT sensors and robotics, their precision agricultural solutions, like the John Deere Precision Planting system, optimize the planting, fertilizing, and harvesting processes to boost crop yields and efficiency.

Also Read: Impact of IoT in the Agriculture Industry

Finance

The merger of robotics and IoT for the finance industry can accomplish tasks such as risk assessment, fraud detection, and automated client support. Real-time financial transaction monitoring by IoT devices allows for detecting irregularities and possible fraud attempts.

The underlying robotics software can automate back-office tasks like data entry, customer service, and even algorithmic trading to increase productivity and decrease human error. For instance, JPMorgan Chase, a leading Fortune 500 financial services company, leverages robotic process automation (RPA) in its back-office operations. They deploy RPA bots to increase operational efficiency and shorten financial transaction processing times by automating data input and reconciliation processes.

Automotive

IoRT-enabled sensors are included in cars for several uses, such as telematics, driver assistance programs, and predictive maintenance. By gathering information on driving behavior, fuel economy, and vehicle performance, these robotics sensors help manufacturers enhance safety features and provide predictive maintenance services. IoRT in the automotive industry improves production efficiency and quality control in manufacturing processes by doing welding, painting, and assembly jobs.

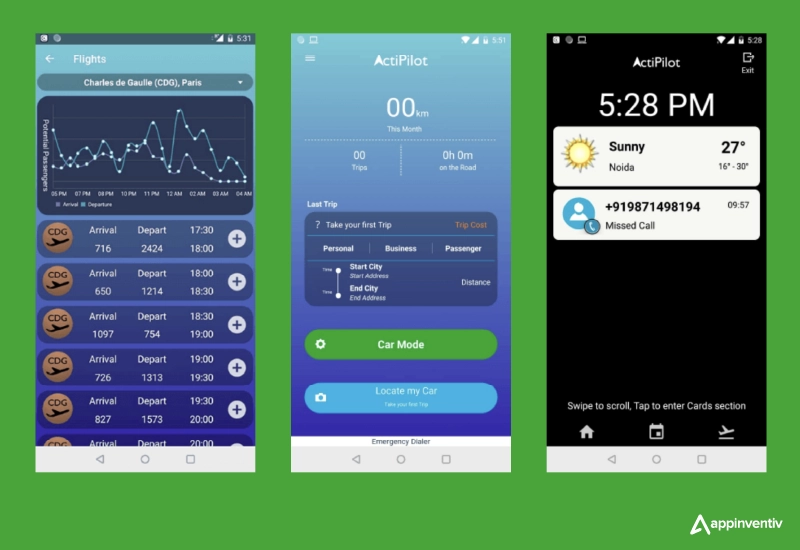

Our experts at Appinventiv developed ActiDrive, a groundbreaking gesture-recognition application built on IoT technology. By harnessing the power of intuitive gestures, ActiDrive empowers drivers to seamlessly access their mobile device’s functionalities without diverting their attention from the road.

This innovative solution prioritizes safety and convenience, allowing drivers to stay connected while keeping their focus on the driving experience. With ActiDrive, drivers can navigate effortlessly and stay connected with unparalleled ease, setting a new standard for in-car connectivity and enhancing the overall driving experience.

Also Read: Real-Time Benefits, Use Cases, and Future of Automotive IoT

Smart Home Appliances

IoT-enabled robots that clean houses and mow lawns are examples of smart home appliances revolutionizing domestic duties. These self-navigating robots provide homeowners with efficiency and convenience in indoor and outdoor areas.

In smart home applications, IoRT technology enables devices to adapt to changing environments, navigate obstacles, and optimize cleaning or maintenance schedules. This integration enhances the comfort and convenience of modern living spaces and frees up occupants’ time for other pursuits.

Whirlpool Corporation, a Fortune 500 manufacturer of home appliances, utilizes IoT-enabled robotics software in their smart appliances. IoT sensors and robots are used in products like the Whirlpool Smart Front Load Washer and Dryer to optimize laundry cycles, increasing user convenience and energy economy.

Also Read: The Future of Smart Homes with IoT in Real Estate

Construction

IoT-enabled robots assist with various jobs in the construction industry, from building inspection and maintenance to site surveying. In difficult conditions, these robots evaluate structural integrity, spot flaws, and repair using sensors and cameras.

Incorporating IoRT technology in construction projects increases productivity, accuracy, and safety. Robots can perform jobs precisely and navigate dangerous environments independently. This integration guarantees adherence to quality and safety standards, expedites project deadlines, and lowers costs.

Caterpillar Inc., a renowned construction and mining equipment manufacturer, incorporates IoT-enabled robotics software in its machinery. Its self-driving excavators and bulldozers are examples of autonomous construction equipment that use robotics and Internet of Things sensors to increase productivity and safety on the job site.

Education

IoT-connected robots are revolutionizing education by giving students immersive and engaging learning experiences. These robots use practical exercises and real-world applications to engage students in learning programming, robotics, or STEM subjects.

Educational institutions can deepen students’ grasp of complicated subjects by enhancing their involvement and comprehension through IoT technology. These robots also help students develop their creativity, problem-solving abilities, and teamwork, which will help them in their future employment.

With its STEM instructional kits, Pearson plc uses robots in classroom environments. Educational institutions can cultivate STEM abilities and experiential learning by introducing children to robots and coding ideas through products like Pearson’s Robots for Kids program.

Energy

IoT and robotics are essential in the energy sector to optimize resource management, increase operational efficiency, and guarantee safety. IoRT sensors enable predictive maintenance and optimize energy output by monitoring environmental factors, equipment performance, and energy consumption in power plants and distribution networks.

Robotics reduces downtime and improves worker safety in hazardous situations by performing jobs like infrastructure inspection, maintenance, and repair. Exxon Mobil Corporation, for instance, integrates IoT-enabled robots into its oil and gas operations. Their use of robotic inspection and maintenance systems, such as drones and remote-operated vehicles (ROVs), enhances safety and efficiency in oilfield operations, reducing downtime and mitigating risks.

Challenges associated with IoT and Robotics Adoption

While implementing IoT with robotics, different challenges might occur that can lead to increased complexities in integration. Let’s have a look at some of the top associated challenges and the solutions to overcome those.

Data Privacy

Collecting and analyzing vast amounts of data from IoT sensors and robotics operations raises concerns about privacy infringement. Safeguarding sensitive and personal information is one of the biggest challenges in data protection law compliance.

Encryption technology and establishing explicit data governance standards can improve data privacy protection. Implementing tactics such as anonymization and data reduction can decrease the gathering and storage of excessive personal information to ensure compliance with data protection requirements.

Security Concerns

IoT devices and robotics systems are susceptible to cybersecurity threats such as hacking, data breaches, and malware attacks.

Implementing robust cybersecurity measures such as encryption, multi-factor authentication, and access control can help mitigate security risks associated with IoT devices and robotics systems. Regular security audits, firmware updates, and intrusion detection systems are essential for proactively identifying and addressing vulnerabilities.

Also Read: How to Ensure Cybersecurity in the Age of IoT

Ethical and Regulatory Challenges

The adoption of IoT and robotics technology is significantly hampered by the need to balance regulatory compliance and ethical considerations. While regulations provide a framework for ensuring safety, privacy, and accountability, ethical dilemmas may arise when regulatory standards fail to adequately address emerging issues.

Therefore, establishing a culture of ethical consciousness and responsibility is vital for organizations. This can be achieved by including varied viewpoints in decision-making procedures and encouraging transparency in creating and implementing IoT and robotics technologies.

Integration with Legacy Systems

Integrating IoT and robotics technologies into legacy systems and existing infrastructure can be difficult because of compatibility issues and the requirement for significant system modifications or retrofitting.

Organizations can use standardized APIs and middleware solutions to solve the problem of integrating robotics and IoT technologies with legacy systems. By resolving compatibility challenges, these technologies enable smooth communication and data interchange between new and old infrastructure.

What Lies Ahead: The Future of IoT Robotics

Despite the current challenges, the future of IoT in robotics holds immense promise, poised to revolutionize industries and redefine daily routines. Enhanced automation and seamless communication will make IoT-enabled robotics software safer, more productive, and more efficient across diverse sectors. Real-time data collection and predictive maintenance capabilities will further optimize operations, minimizing downtime and maximizing efficiency.

Improved flexibility and autonomy will enable robotics software to operate in challenging circumstances and work in unison with people. The combination of IoT and robotics will open up new possibilities as technology develops, paving the way for a time when intelligent, networked robots will be integral to shaping our world.

In addition, the integration of Generative AI into IoRT promises to empower innovation by leveraging its ability to create intuitive designs, automate robotic actions, and optimize manufacturing processes, propelling the field toward unprecedented efficiency and creativity.

How Appinventiv Can Support Your IoT and Robotics Project

Navigating the transition into the era of advanced robotics requires a keen focus on safety and regulatory compliance to ensure seamless human-robot coexistence. Alongside these considerations, there are significant financial benefits, including heightened productivity, cost savings, and avenues for growth. Appinventiv, with its decade-long experience and technical expertise, is ready to help you with your IoRT projects, opening up new opportunities for innovation and efficiency.

Driven by a steadfast commitment to innovation, we ensure that your projects are equipped with the most advanced technological solutions available. Our comprehensive IoT software development services are meticulously crafted to cater to the unique needs of diverse sectors, offering tailored solutions that seamlessly integrate with your objectives. With a proven track record of success, we have consistently supported numerous startups, enterprises, and Fortune 500 companies in navigating their journey toward digital transformation, empowering them to stay ahead in today’s evolving tech landscape.

Trust our experienced team to simplify your IoRT project, optimize your company’s potential, and remain ahead of the competition with innovative solutions. Connect with our experts to get started with your IoT robotics project.

FAQs

Q. What are some of the top trends of the Internet of Robotic Things?

A. Some of the top trends of the Internet of Robotic Things include:

Human-Robot Collaboration: The Internet of Things (IoRT) is propelling development in this field, where humans and robots collaborate in shared workplaces, enhancing each other’s skills and talents. This approach emphasizes efficiency, safety, and smooth communication between people and robots.

Predictive Maintenance: IoRT enables predictive maintenance solutions by monitoring robotic systems’ condition and functionality continuously. This proactive approach helps prevent equipment failures, prolongs robotic device lifespans, and detects sensor data anomalies.

Drones and Autonomous Vehicles: The Internet of Things (IoRT) is propelling the development of drones and autonomous vehicles for a range of uses, such as delivery, transportation, and surveillance.

Edge Computing: IoRT devices are increasingly equipped with edge computing capabilities, enabling data processing and analysis to occur closer to the source of data generation. This reduces latency and bandwidth usage while enhancing real-time decision-making capabilities.

AI and Machine Learning Integration: IoRT systems incorporate advanced AI and machine learning algorithms to enhance robotics autonomy, adaptability, and intelligence. This enables robots to learn from data, make predictions, and optimize their actions in complex environments.

Cybersecurity and Privacy: Due to the growth of linked devices on the Internet of Things, there is a greater emphasis on cybersecurity and privacy safeguards to safeguard sensitive data and guarantee the integrity of robotic systems. This includes implementing access control, authentication, and encryption techniques.

Q. What is the role of IoT in the robotics industry?

A. IoT in robotics is a key enabler of connectivity and data exchange. IoT sensors enable autonomous operation, predictive maintenance, and remote monitoring by gathering and analyzing data from robotic systems.

This connectivity enhances efficiency, reduces downtime, and enables seamless interoperability among robotic devices and other IoT-enabled platforms. Furthermore, IoT robotics helps in data-driven decision-making and performance optimization across a range of applications and industries.

Q. What are some of the benefits of IoT in robotics?

A. Some of the major benefits of IoT in robotics include:

Real-time Monitoring: By gathering and transmitting data in real-time, IoT sensors enable operators to monitor robotic activities remotely and make necessary adjustments promptly.

Predictive Maintenance: Using IoT analytics to anticipate possible problems and failures in robotic systems, proactive maintenance may be carried out to minimize downtime and maximize efficiency.

Enhanced Efficiency: IoT optimizes workflows and boosts robotics’ operational efficiency by automating data collecting and analysis, which raises output and lowers costs.

Greater Autonomy: IoT provides robots with access to vast amounts of data and information, empowering them to make autonomous decisions and adapt to changing environments without human intervention.

Improved Connectivity: The Internet of Things (IoT) allows robotic devices and other linked systems to communicate and exchange data seamlessly, promoting cooperation and interoperability.

Q. How are robotics and IoT evolving together?

A. IoT and robotics are evolving by progressively incorporating connectivity and data exchange capabilities into robotic systems. Robots with inbuilt IoT sensors can gather and analyze data in real-time, enabling them to act independently and adjust to changing surroundings.

Owing to this connectivity, robotic devices and other IoT-enabled systems collaborate and communicate more effectively, promoting automation, efficiency, and intelligence gains. It is anticipated that when these technologies develop further, their integration will further transform businesses and open the door to innovative applications across various fields.

THE AUTHOR

Sudeep Srivastava

Co-Founder and Director