Why we’re seeing more robots inside plants

Long used mostly for the “dull, dirty and dangerous” tasks in manufacturing, robots are increasingly considered “desirable” amid rising labor costs and shortages, strike risks and the need for flexibility in navigating the bumpy electric vehicle transition.

A record contract between the United Auto Workers and the Detroit Three following an up-to 46-day strike last fall might’ve been the final “catalyst” for a boom in investment in more automation, according to Lou Finazzo, a vice president at Japanese robot supplier Fanuc Corp. Some workers at automakers as well as suppliers already are seeing it affect their jobs at assembly plants, too.

UAW Local 2209 Shop Chairman Rich LeTourneau, in recent months, has watched General Motors Co. install new robots inside its body shop at the Fort Wayne Assembly Plant in Indiana. It’s affected about 30 jobs at the three-shift plant. Although nobody is being laid off because of attrition, LeTourneau is concerned about the overall job count going down at the plant. The plant that makes the Chevrolet Silverado and GMC Sierra trucks has more than 4,200 employees, including salaried workers, according to GM’s website.

“They’re working on all kinds of automation all over the whole plant,” LeTourneau said. “We keep hearing there’s gonna be some in general assembly. There’s gonna be some in the material department.”

In a statement, GM spokesperson Kevin Kelly said the automaker is a “people-centric employer” that deploys “technology to aid our team members in making our work environments safer.” The technology aids with quality goals and “helps our team minimize ergonomic stressors and achieve productivity goals which will help ensure the viability of the business for all of us into the future.”

That, however, is likely just a glimpse for what it is to come, say executives and other experts in the industry.

“With the UAW negotiations and the result of higher labor costs, it’s sort of like that last tipping point where a lot more automation programs and requests now are also financially desirable and justifiable,” said Finazzo, contrasting it to the past when a return on the investment in robots could’ve taken four years compared to a more desirable two years. “Now, many of these drop right into available funding based on return on investment.”

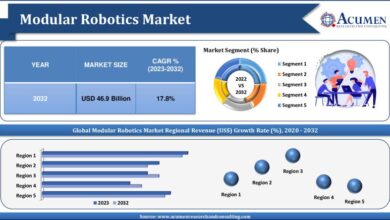

In 2022, the global automotive industry installed 135,000 new industrial robotics, according to the International Federation of Robotics. The only industry to surpass that installation rate was electronics. In 2023, though, robot manufacturers saw a 30% decrease in orders in total across industries, including e-commerce, agriculture and other areas, according to Association for Advancing Automation. Finazzo called it a “reconciliation” after 15% to 20% year-over-year growth during the pandemic compared with a more typical 2½% to 4% annual growth.

Companies bought these robots to take advantage of downtime in response to labor shortages and in preparation for new products as EV demand soared during a low-inventory vehicle environment. But now those timelines are adjusting amid a slower adoption than expected because of affordability, charging infrastructure and range anxiety challenges. On top of that, a shortage of robot technicians and other integration workers to install the machines have resulted in a consumption problem, Finazzo said.

As a result of shifting EV program timelines, there’s greater uncertainty on when a new program will launch, which offers a smaller window for the integration of robots, Finazzo said: “That is putting a little bit of labor pressure on us, as well, to align with their programs and timing.”

Automation at Detroit Three plants

In addition to the truck plant at Fort Wayne, GM is also increasing automation at aftersale parts distribution centers. It pointed to work being done at a warehouse in Charlotte, North Carolina, that is reducing stress on workers. GM is investing $23 million there to modernize operations at the facility.

The investment will be used to maximize storage, reduce physically demanding work and improve order fulfillment times by implementing an automated storage and retrieval system where machines pull specific parts from shelving to reduce how much walking and lifting employees have to do; robotics and conveyance systems to bring materials to employees; and autonomous mobile robots to bring orders to employees for shipping.

GM also made more than $120.5 million in investments at its Customer Care and Aftersales facilities in Memphis, Tennessee; Ypsilanti and Burton near Flint. These investments also brought new technology to increase workplace safety.

According to the company’s contract with the UAW, it must notify the local union about the introduction of “new or advanced technology” to allow “meaningful discussion of its impact.” If unresolved issues ensue, the contract does outline a grievance procedure.

The UAW didn’t provide comment on automation in response to multiple inquiries.

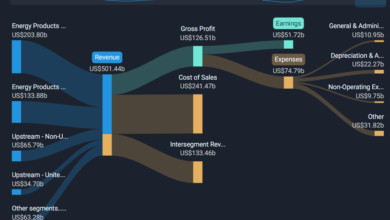

Ford Motor Co. says this year it’s cutting $2 billion to cover increased labor and product refreshments costs. On an investor call late last year, Chief Financial Officer John Lawler mentioned “opportunities in automation” in reference to covering the cost of the new UAW contract, in addition to reductions in vehicle combinations.

In a news release last week, the Dearborn automaker highlighted that its new Tennessee Electric Vehicle Center, set to begin deliveries of its next-generation electric truck in 2026, will be the automaker’s first “Industry 4.0 plant, combining automation and connectivity to help elevate quality and efficiency.”

Ford declined an interview to discuss its automation plans.

During a tour of its Dearborn Truck Plant producing F-150 trucks on Thursday in Dearborn, Plant Manager Corey Williams emphasized many of the technologies being added to the plant are to simplify workers’ jobs or make them more efficient. With the 2024 refresh of the pickup, he pointed to additional cameras added during the quality check process to flag fixes up the line.

“A lot of people think it’s a reduction or replacement,” Williams said of new technologies in manufacturing. “It’s not. It’s more of how to use technology to enhance the job or make it easier.”

At Stellantis NV, Mark Stewart, the Ram and Jeep truck maker’s former chief operating officer in North America, during last fall’s negotiations, discussed modernizing its Mopar aftersales parts plants to be more like Amazon.com Inc.’s fulfillment centers. He said there wouldn’t be any jobs eliminated from these updates.

Stellantis CEO Carlos Tavares earlier this year said much of the company’s body-in-white welding and paint shops have high rates of automation, while general assembly is trickier because the work there is more variable and tends to be more complicated to program, like grabbing the correct item from a bin. But Tavares emphasized in thinking about the matter that it’s the company’s job to provide affordable vehicles. It sees “transformation” as “less of this here, more of that over there.”

“You’ll need more people, perhaps making batteries or making the electric drivetrains,” he said, adding there might be less people in general assembly if there is more automation.

Foreign automakers, like South Korean automaker Hyundai Motor Co., are also diving into robots helping run assembly plants. Late last year, Hyundai revealed its Hyundai Motor Group Innovation Center Singapore, which introduced a “smart urban mobility hub” concept with its “highly automated flexible production system.”

Inside the facility, about 50% of all tasks are completed by 200 robots with human collaboration, according to Hyundai.

General assembly has been the focus of research and development for the past several years, Fanuc’s Finazzo said. It offers the most potential for revenue growth. Finazzo expects general assembly will see the largest growth in automation over the next five years as companies rethink assembly and manufacturing in response to challenges with finding enough workers.

The solutions often involve smaller, faster robots or ones with a longer or more accurate reach. Additionally, it presents opportunities for Fanuc’s collaborative robots that are designed with greater safety in mind by being able to stop when they bump into something or someone.

The biggest gains in efficiency, though, typically come from robots being able to put multiple steps together to create one part, said Mark Wakefield, global co-leader of the automotive and industrial practice at consulting firm AlixPartners LLP.

“The savings from that dwarf being slightly faster, more repeatable in the operations,” he said.

Robotic increases across the industry

Suppliers — especially tier-one operators with more capital to invest, facing labor supply issues and the need to quickly adapt in the EV transition — are also turning to robots for help. Forvia SE, a French auto supplier formed in 2022 after Faurecia SE acquired Hella KGaA Hueck & Co., is one of those.

The world’s seventh-largest auto supplier has installed highly automated flexible door assembly lines at plants in southeast Michigan’s Saline and Spring Hill, Tennessee.

The automated line is more adaptable than the standard comparison operated mostly by humans. Forvia says it can use this automated line to adjust more easily to customer needs, including with volume and variants, which is helpful in the transition to EVs when automakers are guessing what demand will be.

“We’re seeing the customers’ low volume, high variability, and so being able to adapt to what the customer actually wants to build, this line is perfect for it,” said Matt Myrand, digital transformation director for North America for Forvia.

The highly automated line is also a way to achieve higher quality. The standard line requires more manual handling, while on the automated line the doors are inside what’s called a “nest” getting the welds it needs. Here, the door is more “protected,” he explained.

And then there’s the people aspect. Forvia, like other suppliers, has had a “hard time finding labor,” Myrand said: “Being able to find the people to run it, improved quality and then really being flexible and modular are the key topics in why we drive towards that.”

Automation also increases with new plants, AlixPartners’ Wakefield said. There’s more construction ongoing in the industry with the move to electrification.

“Automation in existing plants is suboptimal,” he said. With new construction, it’s designed to be “built upfront and optimized.” Automation that works well won’t just replace labor, he added. It creates quality improvements, too, such as reducing scraps.

But there are downsides. More automation can make a line less flexible, which can be a challenge when something goes wrong for just-in-time parts delivery. Additionally, when something goes wrong, fixing it can take time, so companies have to factor in efficiency gains and costs related to maintenance and repairs.

Fanuc’s newer robots connect to the cloud, and manufacturers can pay a subscription to receive information on when a robot might need maintenance to avoid downtime.

Other ways industry players are looking at cost savings include potentially investing in Mexico, where labor is less expensive and manufacturers can take advantage of tariff-free trade under the United States-Mexico-Canada agreement, Wakefield said. In public remarks earlier this year, Ford CEO Jim Farley suggested the automaker would “think carefully” about its manufacturing footprint after its Kentucky Truck Plant was the first truck plant hit in the UAW’s targeted strike last fall, despite Ford building all of its full-size trucks in the United States and it employing more UAW members than its crosstown rivals.

Tom Kelly, president of Automation Alley, which calls itself “Michigan’s Industry 4.0 Knowledge Center,” says the industry needs to move faster to increase automation. Doing so could increase jobs here rather than seeing them go to lower-cost countries like China and Mexico since the automation offsets the cost of labor.

“The rubber band’s been pulled so far to the low-cost labor countries that, now, automation is actually our friend,” he said. “It allows us to compete and bring jobs back, and you’re seeing that around the U.S. You’re seeing this reshoring, and it’s actually creating manufacturing jobs, over the last year, not destroying them because we’re able to pay higher wages and actually get the workforce.”

Fanuc contends robots don’t take away jobs, Finazzo said. He emphasized how the largest generation, baby boomers, also are retiring and leaving the workforce without people to fill the jobs.

New jobs are also created, such as robot technicians to install, maintain and repair machines. Fanuc, in the past few years, resumed an apprentice program and has expanded education programming to as young as elementary school.

“We are showing that it’s a great career,” Finazzo said. “It’s a great way to make a good living and raise a family, and you’re using your mind, not your back. I think the stigma around working in a plant was it’s very physical. Now, it’s very mental.”